Alkaline cleaning composition for dairy product processing equipment and preparation method of alkaline cleaning composition

A technology for cleaning compositions and processing equipment, applied in the field of cleaning agents, can solve the problems of large environmental impact, large equipment burns, strong corrosiveness, etc., and achieves good cleaning effect, short defoaming time, and low corrosiveness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

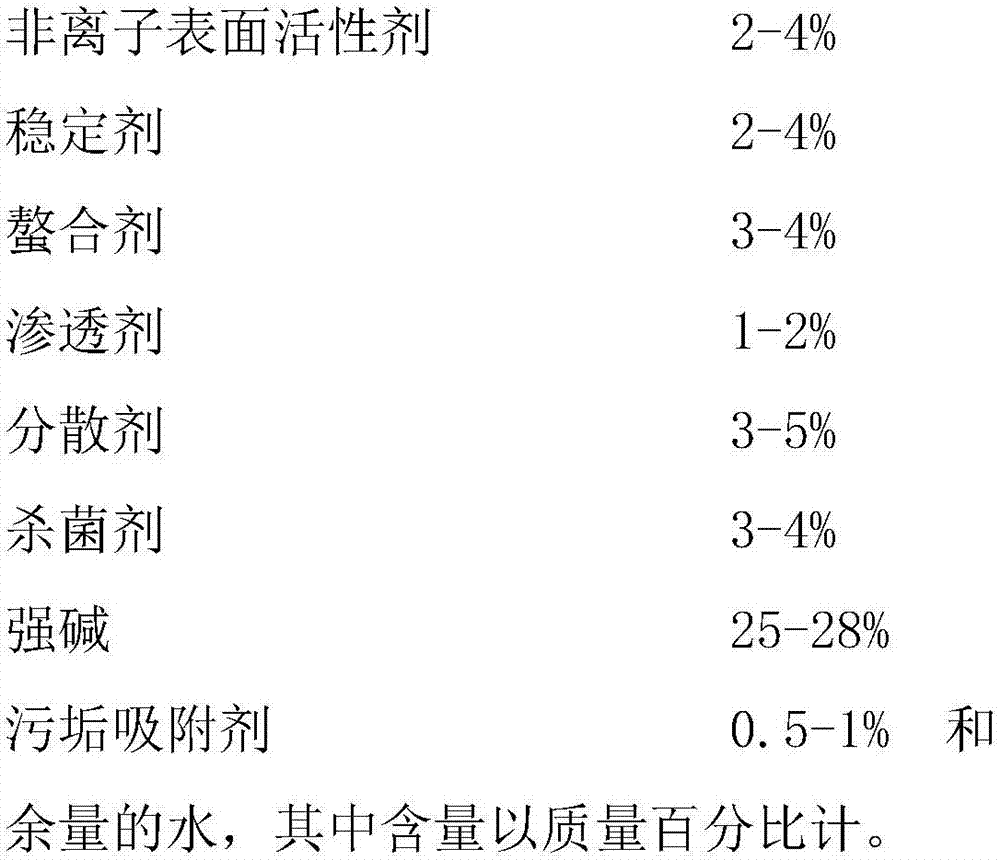

[0050] The alkaline cleaning composition for dairy processing equipment disclosed in Example 1 is composed of a mixture of 2% alkyl glycoside (APG IC06), 2% sodium silicate and sodium carbonate (sodium silicate: sodium carbonate = 1:1, by mass ratio), 2% tetrasodium 2-phosphonic acid butane-1,2,4-tricarboxylate, 1% AEO7-Me, 3% sodium polyacrylate, 3% sodium hypochlorite , 25% sodium hydroxide, 0.5% hydroxypropyl distarch phosphate, and the balance is water, and the content of each component is calculated by mass percentage.

[0051] The preparation method is:

[0052] According to the above ratio, mix deionized water and strong alkali, stir until dissolved;

[0053] Add chelating agent, dispersant, fungicide, and stabilizer in sequence, stir until dissolved, and control the reaction temperature at 50°C during the stirring process;

[0054] Add penetrant, non-ionic surfactant, and dirt adsorbent in sequence, stir until the solution is completely dissolved and the solution is ...

Embodiment 2

[0062] The alkaline cleaning composition for dairy processing equipment disclosed in Example 2 is composed of a mixture of 4% alkyl glycoside (APG IC06), 3% sodium silicate and sodium carbonate (sodium silicate: sodium carbonate = 4:3, by mass ratio), 4% tetrasodium 2-phosphonic acid butane-1,2,4-tricarboxylate, 2% AEO9-Pr, 5% sodium polyacrylate, 4% sodium hypochlorite , 28% sodium hydroxide, 0.8% hydroxypropyl distarch phosphate, and the balance is water, and the content of each component is calculated by mass percentage.

[0063] The preparation method is:

[0064] According to the above ratio, mix deionized water and strong alkali and stir until dissolved;

[0065] Add chelating agent, dispersant, bactericide, and stabilizer in sequence, stir until dissolved, and control the reaction temperature at 55°C during the stirring process;

[0066] Add penetrant, non-ionic surfactant, and dirt adsorbent in sequence, stir until the solution is completely dissolved and the solutio...

Embodiment 3

[0074] The alkaline cleaning composition for dairy processing equipment disclosed in Example 3 is composed of a mixture of 2% alkyl glycoside (APG IC06), 2% sodium silicate and sodium carbonate (sodium silicate: sodium carbonate = 1:1, by mass ratio), 2% sodium gluconate, 1% AEO7-Pr, 3% sodium polyacrylate, 3% sodium hypochlorite, 28% sodium hydroxide, 2% hydroxypropyl di Starch phosphate, the balance is water, and the content of each component is calculated by mass percentage.

[0075] The preparation method is:

[0076] According to the above ratio, mix deionized water and strong alkali and stir until dissolved;

[0077] Add chelating agent, dispersant, bactericide, and stabilizer in sequence, stir until dissolved, and control the reaction temperature at 60°C during the stirring process;

[0078] Add penetrant, non-ionic surfactant, and dirt adsorbent in sequence, stir until the solution is completely dissolved and the solution is clear and transparent, and cool to room te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com