A modified polymer microporous membrane and a preparing method thereof

A polymer and microporous membrane technology, applied in chemical instruments and methods, membrane, membrane technology, etc., can solve the problems of degradation of modification effect, decline of membrane mechanical properties, poor compatibility, etc., and achieve simple process, mild conditions, The effect of stabilizing surface properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

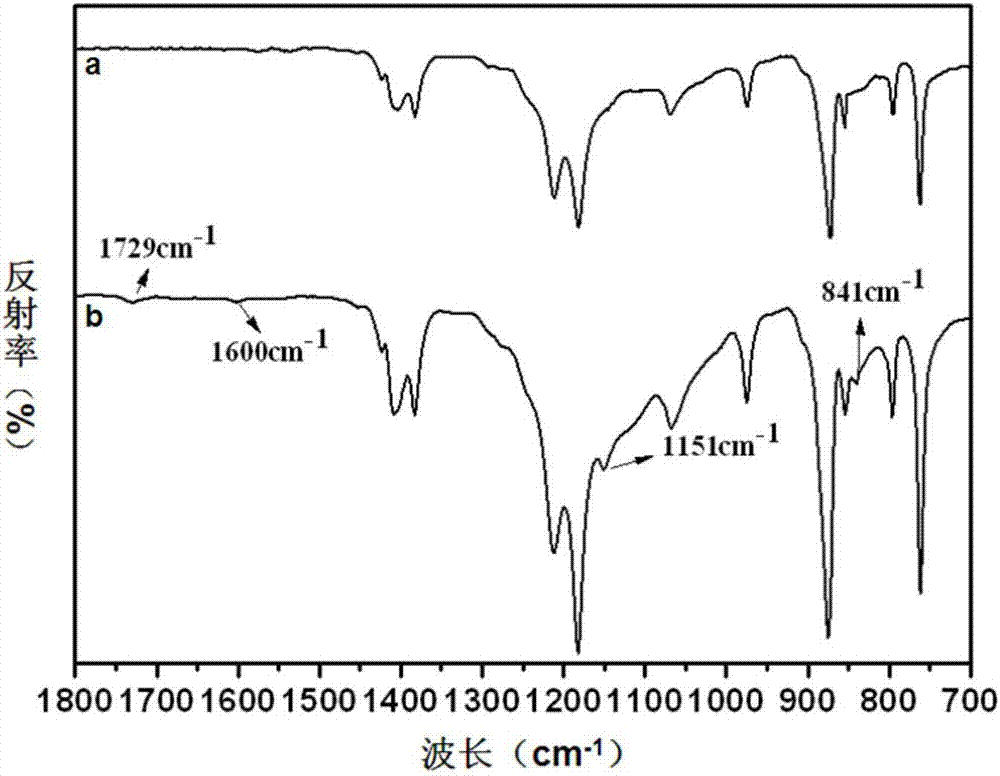

[0028] The invention provides a preparation method of a modified polymer microporous membrane, which comprises the following steps:

[0029] S1, providing a siloxane prepolymerization solution, and diluting the siloxane prepolymerization solution with a diluent;

[0030] S2, placing the polymer microporous membrane in the diluted siloxane prepolymer solution for immersion treatment; and

[0031] S3, performing a pre-crosslinking reaction on the impregnated polymer microporous membrane to obtain the modified polymer microporous membrane.

[0032] In step S1, the diluent is used to dilute the siloxane prepolymer solution. The diluent is a mixture of water and ethanol. The mixing ratio of the water and ethanol is not limited. The volume ratio of the siloxane prepolymer liquid to the diluent is 1:4˜4:1.

[0033] The preparation method of described siloxane prepolymer liquid is as follows:

[0034] S11, adding polyalkoxysilane, functional monomer and initiator into an inert or...

Embodiment 1

[0054] (1) Add 3g of hydroxyethyl methacrylate, 2g of vinyltrimethoxysilane and 0.06g of benzoyl peroxide to 100mL of dehydrated ethanol in turn, pass through industrial nitrogen, and 200r at room temperature / min Mechanical stirring for 20min. Then turn on the heating and gradually increase the temperature to 65° C., and react with mechanical stirring at 200 r / min for 36 hours in an industrial nitrogen atmosphere. Turn off the heating, and obtain a hydrophilic hydroxyethyl methacrylate / vinyltrimethoxysilane copolymer prepolymer liquid after cooling down sufficiently. Add 40mL of deionized water to the obtained 100mL prepolymerization solution to obtain a diluted prepolymerization solution.

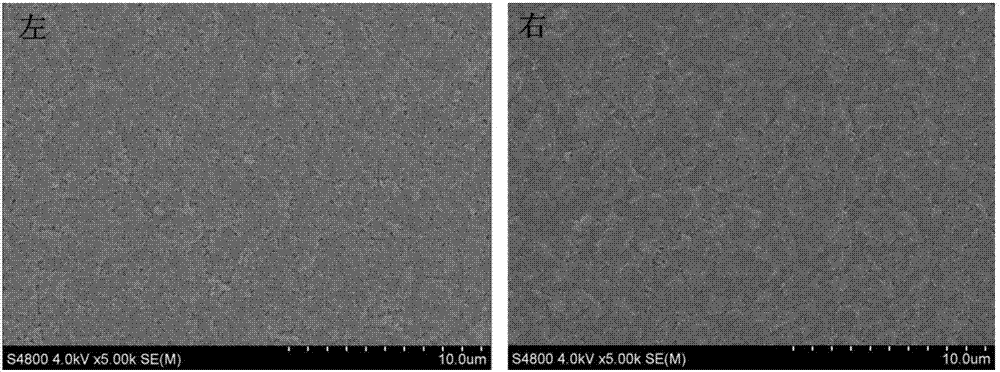

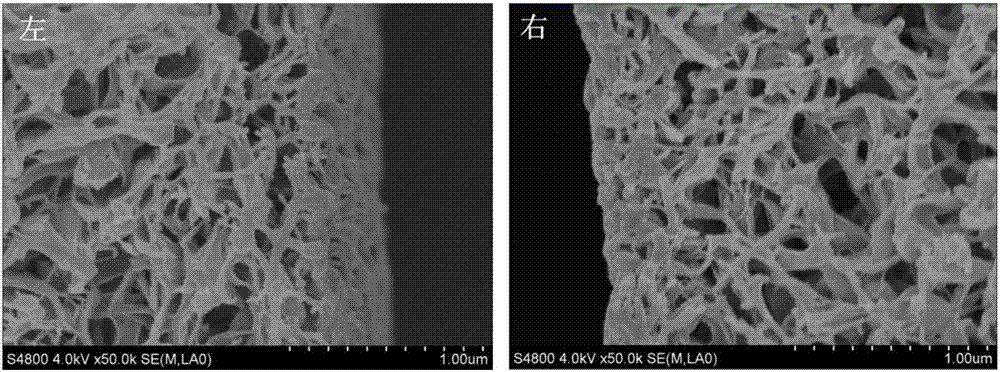

[0055] (2) Soak the polysulfone microporous membrane with a surface average pore diameter of 500nm into the diluted pre-polymerization solution, remove the air bubbles in the pre-polymerization solution by shaking, and then soak for 5 hours.

[0056] (3) Take out the polysulfone micropo...

Embodiment 2

[0059] (1) Add 4g of N-vinylpyrrolidone, 3g of vinyltriethoxysilane and 0.1g of azobisisoheptyl cyanide to 100mL of triethyl phosphate successively, feed high-purity nitrogen, and Mechanically stir at 250r / min for 30min at room temperature. Then turn on the heating and gradually increase the temperature to 80°C, and react with mechanical stirring at 250r / min for 24 hours in an industrial nitrogen atmosphere. Turn off the heating, and obtain a hydrophilic N-vinylpyrrolidone / vinyltriethoxysilane copolymer prepolymer liquid after cooling down sufficiently. Add 100 mL of 50% ethanol aqueous solution to the obtained 100 mL prepolymer solution to obtain a diluted prepolymer solution.

[0060] (2) Soak the polyvinylidene fluoride pore membrane with a surface average pore diameter of 2 μm in the diluted pre-polymerization solution, remove air bubbles in the pre-polymerization solution by shaking, and then soak for 2 hours.

[0061] (3) Take out the polyvinylidene fluoride porous mem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com