Autoclaved brick prepared from sodium jarosite residue, and preparation method thereof

A technology of jarosite slag and autoclaved bricks, which is applied in the field of building materials, can solve problems such as land occupation, environmental pollution, and environmental threats, and achieve the effects of saving resources, wide sources, and good physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

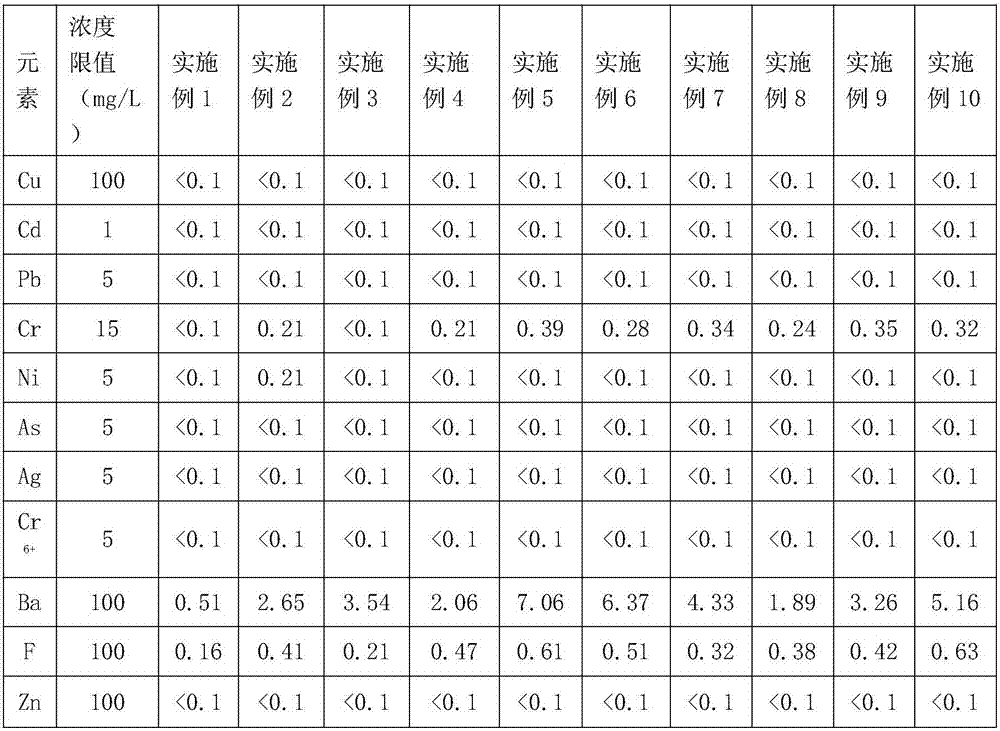

Examples

Embodiment 1

[0033] A preparation method of an autoclaved brick made of jarosite slag, comprising the following steps:

[0034] S1: Airing or drying the jarosite slag until the moisture content is ≤20%;

[0035] S2: Grind tempered slag and wollastonite to <0.08mm respectively;

[0036] S3: Weigh the raw materials according to the following parts by weight: 300 parts of jarosite slag, 350 parts of cement, 100 parts of wollastonite, 8 parts of naphthalene-based water reducer, 8 parts of iron oxide red, and 30 parts of artificial sand;

[0037] S4: Put the measured jarosite slag, cement, wollastonite powder, and artificial sand into the wheel mill mixer for dry material rolling and mixing for 10 minutes;

[0038] S5: Add the measured naphthalene-based water reducer and red iron oxide into an appropriate amount of water and mix well, then add them to the wheel mill and roll and stir with the dry materials for 10 minutes to make the bricks form a semi-dry and wet brick with an appropriate degr...

Embodiment 2

[0043] A preparation method of an autoclaved brick made of jarosite slag, comprising the following steps:

[0044] S1: Airing or drying the jarosite slag until the moisture content is ≤20%;

[0045] S2: Grind tempered slag and wollastonite to <0.08mm respectively;

[0046] S3: Weigh the raw materials according to the following parts by weight: 800 parts of jarosite slag, 100 parts of cement, 190 parts of tempered slag, 10 parts of calcium lignosulfonate, 15 parts of iron oxide yellow, and 50 parts of natural sand;

[0047] S4: Put the measured jarosite slag, cement, tempered slag powder, and natural sand into the wheel mill mixer for dry material rolling and mixing for 15 minutes;

[0048] S5: Add the measured calcium lignosulfonate and iron oxide yellow into an appropriate amount of water and mix well, then add them to the wheel mill and roll and stir with the dry materials for 15 minutes to make the bricks form a semi-dry and wet brick with an appropriate degree of cohesion...

Embodiment 3

[0053] A preparation method of an autoclaved brick made of jarosite slag, comprising the following steps:

[0054] S1: Airing or drying the jarosite slag until the moisture content is ≤20%;

[0055] S2: Grind tempered slag and wollastonite to <0.08mm respectively;

[0056] S3: Weigh the raw materials according to the following parts by weight: 800 parts of jarosite slag, 350 parts of cement, 20 parts of polycarboxylate water reducing agent, 20 parts of iron oxide black, and 75 parts of artificial sand;

[0057] S4: Put the measured jarosite slag, cement, and artificial sand into the wheel-mill mixer for rolling and stirring for 15 minutes;

[0058] S5: Add the measured polycarboxylate water reducer and iron oxide black to an appropriate amount of water and mix well, then add them to the wheel mill and dry them together with the dry materials for rolling and stirring for 15 minutes to make the bricks form a proper degree of cohesion Semi-dry and wet uniform brick materials; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com