Wood preservative

A technology of wood preservatives, parts by weight, applied in wood treatment, impregnation of wood, wood impregnation, etc., can solve the problems of anti-wood rot fungus, narrow range of insects, single preservative performance, environmental and human hazards, etc., to achieve Excellent antibacterial properties, excellent stability, and high efficacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

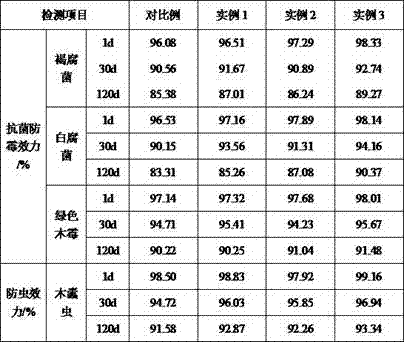

Examples

example 1

[0019] According to the mass ratio of 1:4, weigh cornstarch and deionized water to mix, stir and mix at 800r / min for 1h to obtain cornstarch dispersion, add cornstarch dispersion quality 3% sodium periodate to the cornstarch dispersion , after stirring and mixing for 20 minutes, adjust the pH value to 4.0 with a mass fraction of 15% hydrochloric acid solution to obtain a mixed solution, put the mixed solution into a three-necked flask, put it in a water bath, set the temperature of the water bath to 80°C, keep stirring for 3 hours, and react After the end, mix the reactant with acetone at a mass ratio of 1:10, stir and mix for 30 minutes, and then filter to obtain a filter residue, put it in an oven, and dry it for 5 hours at a temperature of 55° C. to obtain modified starch, at a mass ratio of 3:2: 1. Mix nonylphenol polyoxyethylene ether, dodecyl dimethyl betaine and sodium benzoate respectively to obtain a mixed solution, then mix the mixed solution with soybean oil at a mas...

example 2

[0021] According to the mass ratio of 1:4, weigh cornstarch and deionized water to mix, stir and mix at a speed of 9000r / min for 1h to obtain a cornstarch dispersion, add 4% of the cornstarch dispersion to the cornstarch dispersion quality sodium periodate , after stirring and mixing for 25 minutes, adjust the pH value to 4.5 with a mass fraction of 15% hydrochloric acid solution to obtain a mixed solution, put the mixed solution into a three-necked flask, put it in a water bath, set the temperature of the water bath to 85°C, keep stirring for 4 hours, and react After the end, mix the reactant with acetone at a mass ratio of 1:10, stir and mix for 40 minutes, and then filter to obtain a filter residue, put it in an oven, and dry it at 60°C for 6 hours to obtain modified starch, at a mass ratio of 3:2: 1. Mix Tween-20, dodecylsulfopropyl betaine and triadimenol respectively to obtain a mixed solution, then mix the mixed solution with peanut oil at a mass ratio of 1:2, stir and m...

example 3

[0023] According to the mass ratio of 1:4, weigh cornstarch and deionized water to mix, stir and mix at a speed of 1000r / min for 2h to obtain a cornstarch dispersion, add cornstarch dispersion quality 5% sodium periodate to the cornstarch dispersion , after stirring and mixing for 30 minutes, adjust the pH value to 5.0 with a mass fraction of 15% hydrochloric acid solution to obtain a mixed solution, put the mixed solution into a three-necked flask, put it into a water bath, set the temperature of the water bath to 90°C, keep stirring for 5 hours, and react After the end, mix the reactant with acetone at a mass ratio of 1:10, stir and mix for 50 minutes and then filter to obtain a filter residue, put it in an oven, and dry it at 65°C for 7 hours to obtain modified starch, at a mass ratio of 3:2: 1. Mix Span 80, lauryl ethoxy sulfobetaine and dimethyl fumarate respectively to obtain a mixed solution, then mix the mixed solution with sesame oil at a mass ratio of 1:2, at 500r / min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com