Method of treating nitric-acid-type fluorine-bearing ammonia-nitrogen-containing wastewater

A technology for ammonia nitrogen wastewater and treatment methods, which is applied in metallurgical wastewater treatment, water/sewage treatment, heating water/sewage treatment, etc., can solve the problems of limited treatment process, high treatment requirements, secondary pollution, etc., and achieve simple process, The treatment conditions are mild and the effect of promoting adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

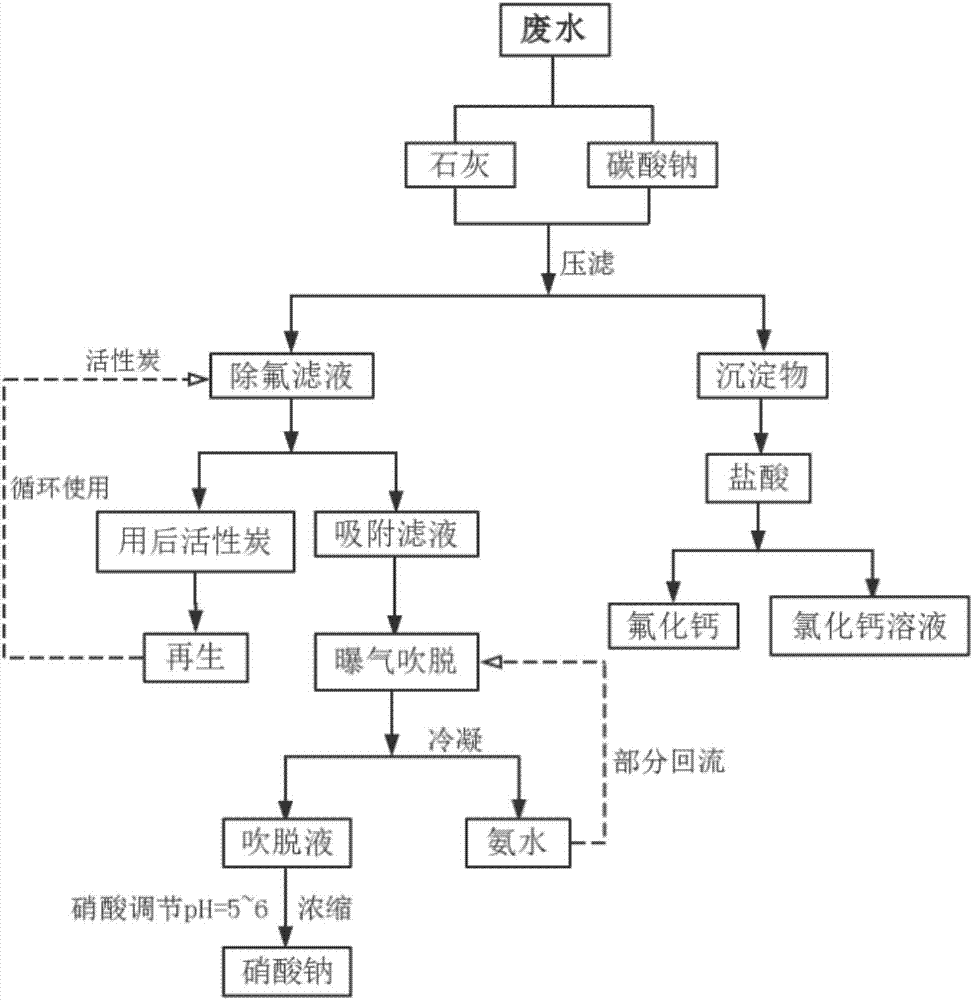

Image

Examples

Embodiment 1

[0028] During the smelting process of a certain metal, a large amount of nitric acid-type fluorine-containing ammonia nitrogen-containing wastewater was produced, in which the fluorine content was 5g / L, the ammonia nitrogen content was 2g / L, and the COD and BOD content were 4g / L. The following procedures are now used for processing:

[0029] Get 1 ton of above-mentioned waste water, successively add the lime that quality is 4 times of fluorine content, 3% sodium carbonate (unit is kg / L) in waste water, press filter after stirring 1h and obtain defluoridation filtrate (fluorine content 3.16ppm) and Precipitate; Precipitate is dissolved in the hydrochloric acid solution of 30wt% by solid-to-liquid ratio 1:1.5 (unit is kg / L), pressure filtration separates after reaction 2h and obtains calcium chloride solution (calcium chloride content 42.5wt%) and Calcium fluoride (purity 98.3%). The obtained calcium chloride solution is colorless and transparent, the specific gravity can reach...

Embodiment 2

[0033] During the smelting process of a certain metal, a large amount of nitric acid-type fluorine-containing ammonia-nitrogen-containing wastewater was produced, in which the fluorine content was 5.5g / L, the ammonia nitrogen content was 2.5g / L, and the COD and BOD content were 4.5g / L. The following procedures are now used for processing:

[0034] Get 1.5 tons of above-mentioned waste water, successively add the lime that quality is 4.5 times of fluorine content, 4% sodium carbonate (unit is kg / L) in waste water, press filter after stirring 2h and obtain defluoridation filtrate (fluorine content 4.86ppm) and Precipitate: Dissolve the deposit in the hydrochloric acid solution of 30wt% by solid-liquid ratio 1:1.8 (unit is kg / L), press filter and separate after reacting 3h to obtain industrial grade calcium chloride solution (calcium chloride content 45wt%) With calcium fluoride (purity 99.1%). The obtained calcium chloride solution is colorless and transparent, the specific gra...

Embodiment 3

[0038] During the smelting process of a certain metal, a large amount of nitric acid-type fluorine-containing ammonia-nitrogen-containing wastewater was produced, in which the fluorine content was 6g / L, the ammonia nitrogen content was 3g / L, and the COD and BOD content were 5g / L. The following procedures are now used for processing:

[0039] Get 2 tons of above-mentioned waste water, successively add the lime that quality is 5 times of fluorine content, 5% sodium carbonate (unit is kg / L) in waste water, press filter after stirring 3h and obtain defluoridation filtrate (fluorine content 6.58ppm) and Precipitate: The deposit is dissolved in the hydrochloric acid solution of 30wt% by solid-to-liquid ratio 1:2 (unit is kg / L), press filter separation after reaction 4h obtains technical grade calcium chloride solution (calcium chloride content 48.5wt%) ) and calcium fluoride (purity 99.3%). The obtained calcium chloride solution is colorless and transparent, the specific gravity ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com