Method for determining content of chromium in paper-making reconstituted tobacco

A technology for reconstituted tobacco leaves and chromium content, applied in measuring devices, color/spectral characteristic measurement, and material analysis through optical means, can solve the problems of high detection limit, cumbersome maintenance, low sensitivity, etc., and achieve convenient maintenance, Safe and efficient operation, the effect of meeting the detection requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

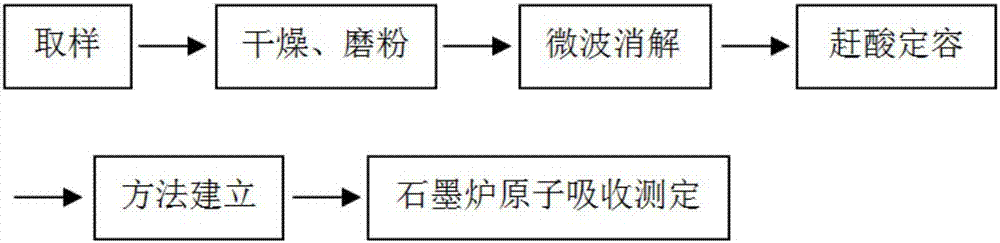

Method used

Image

Examples

Embodiment 1

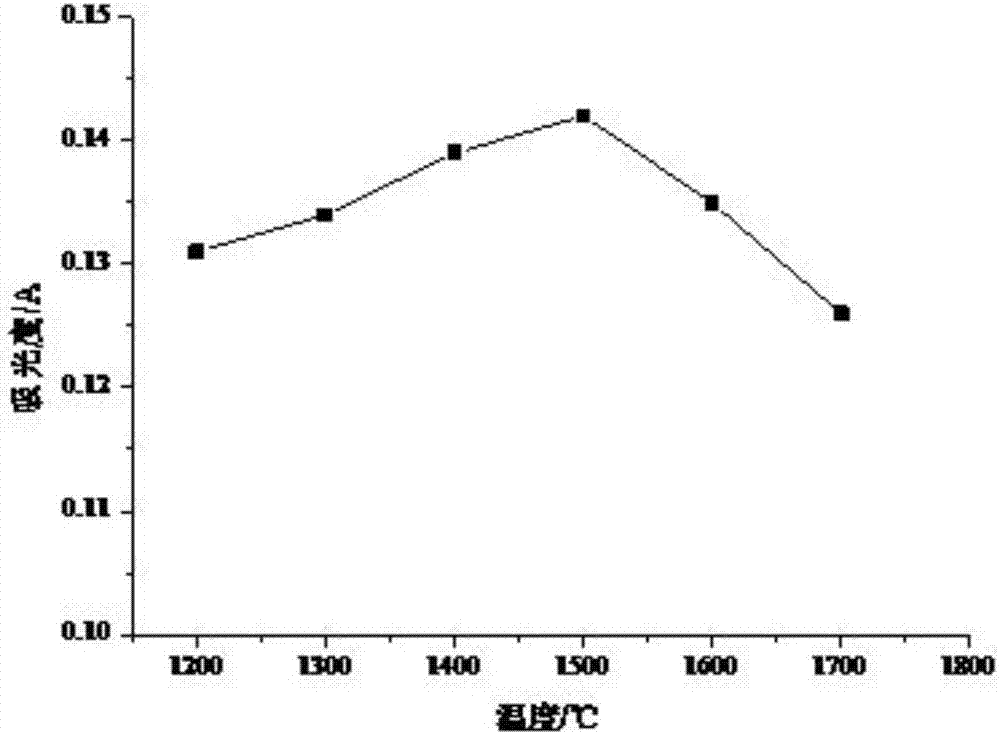

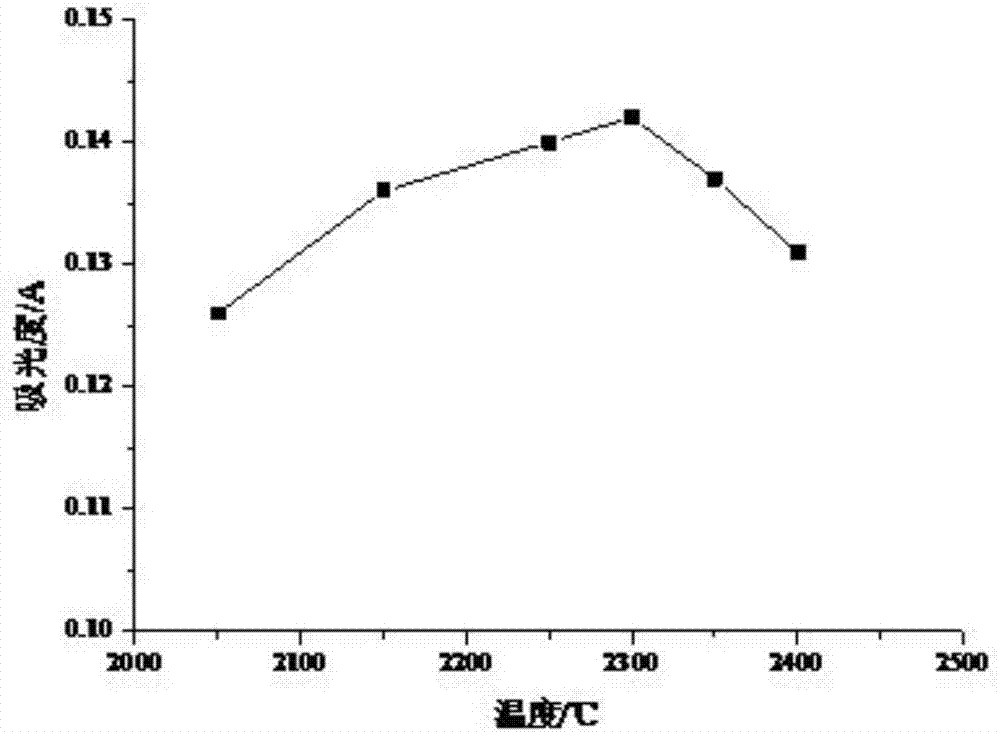

[0083] 1. Instruments and reagents: graphite furnace atomic absorption spectrometer. High-throughput closed microwave digestion instrument (equipped with TFM microwave digestion tank). Acid catcher. Plastic volumetric flask (50mL). Electronic balance (sensitivity 0.000 1g). Laboratory pure water meter. whirlwind mill. Electric blast drying oven. 1000μg / mL chromium standard solution, 10000mg / L palladium nitrate (excellent grade). 65% nitric acid (excellent grade). 37% hydrochloric acid (excellent grade). 40% hydrofluoric acid (excellent grade). Argon (99.999% pure). Ultrapure water (conductivity 18.2MΩ·cm).

[0084] 2. Sample treatment: Weigh a certain amount of reconstituted tobacco leaf samples, put them in an oven at 100-110°C to dry for 4 hours, crush them to 40 meshes, and place them in a desiccator for later use. Accurately weigh 0.2g of powdered reconstituted tobacco leaf sample, accurate to 0.0001g, place it in a 50mL microwave digestion tank, add 5mL of 65% ...

Embodiment 2

[0087] As described in Example 1, a reconstituted tobacco leaf sample with brand A was selected, and its chromium content was measured to be 1.82 mg / kg.

Embodiment 3

[0089] As described in Example 1, a reconstituted tobacco leaf sample with brand C was selected, and its chromium content was measured to be 3.74 mg / kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com