Gliclazide sustained-release tablets

A technology for gliclazide and sustained-release tablets, which is applied in the field of gliclazide sustained-release tablets and their preparation, can solve the problems of reaching a very high blood drug concentration, low medication compliance of patients, and many daily doses, and the like. The effect of stable drug release rate, good drug stability and high bioavailability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

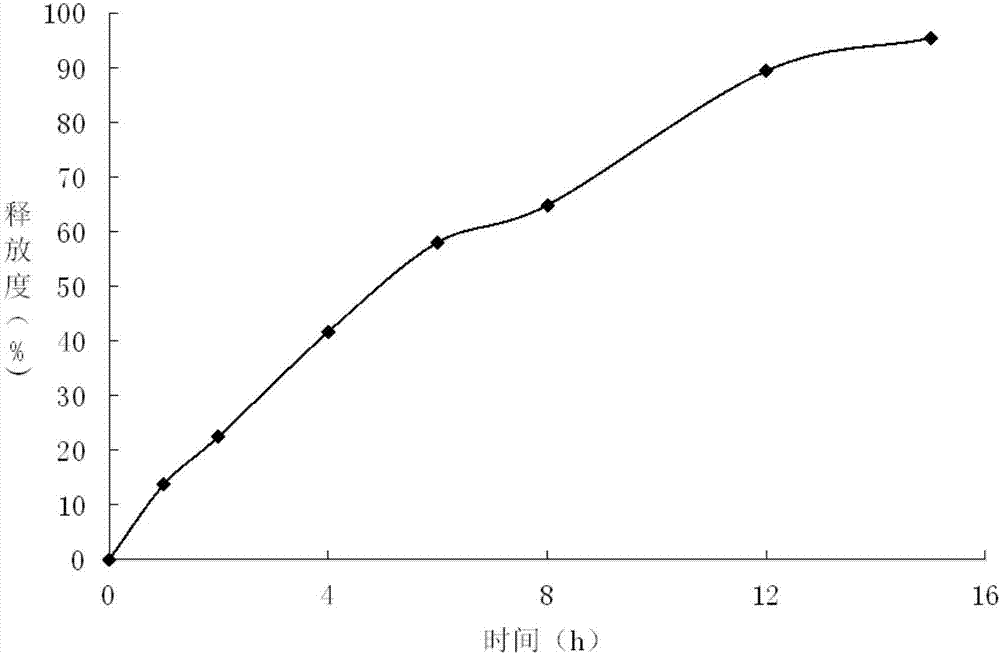

Examples

Embodiment 1

[0028] Embodiment 1 Meglumine dosage screening test

[0029] Weigh glyceryl behenate, divide it into 6 equal portions, 90g each, heat to 65-70°C to melt respectively, add meglumine 1, 2, 4, 8, 12, 16g, under the condition of keeping warm at 65-70°C, add 30g of gliclazide respectively, stir for 60min with an electric stirrer, and observe whether the gliclazide melts.

[0030] Table 1: Meglumine Dosage Screening

[0031] Meglumine Dosage

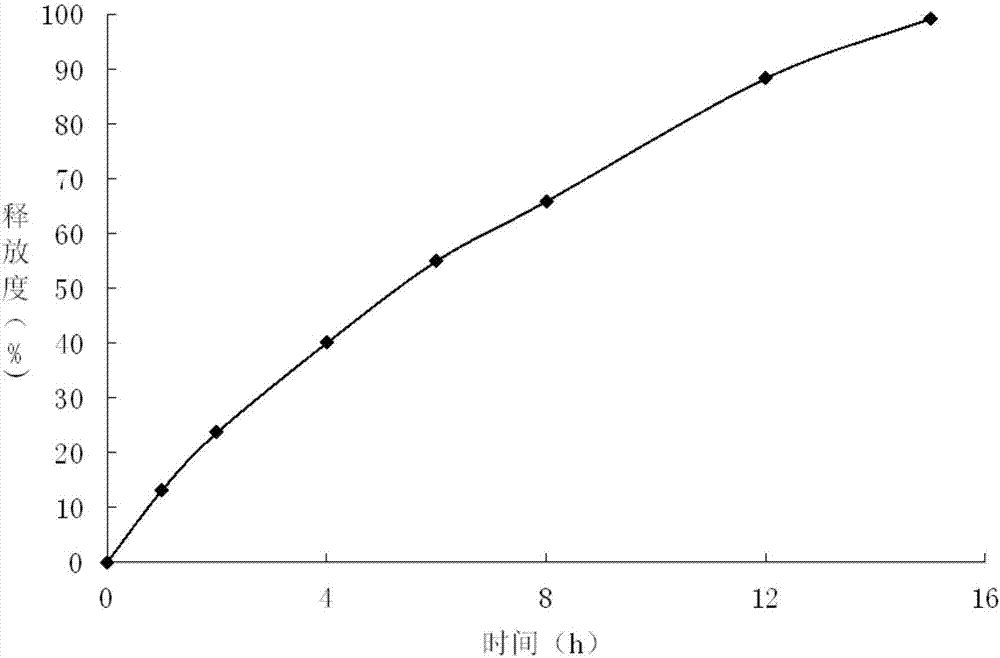

Embodiment 2

[0032] Preparation of Embodiment 2 Gliclazide Sustained-release Tablets

[0033]

[0034] Preparation Process:

[0035] ①Take glyceryl behenate, heat to 65-70°C to melt, keep warm and add the prescribed amount of meglumine while stirring;

[0036] ②Continue to keep warm at 65-70°C, add gliclazide at the same time, use an electric stirrer to stir for more than 30 minutes until it melts, quickly put it into ice-water mixture to solidify, and put it in a desiccator to dry after it is completely solidified, and the drying temperature is lower than 60 ℃, drying time is 2h, grind, and pass through 80 mesh sieve to obtain drug-loaded granules;

[0037] ③Mix the drug-loaded granules with the prescribed amount of mannitol (passed through a 100-mesh sieve) and magnesium stearate evenly, and press into tablets, Φ9mm punched tablets, and control the hardness within the range of 40-60N.

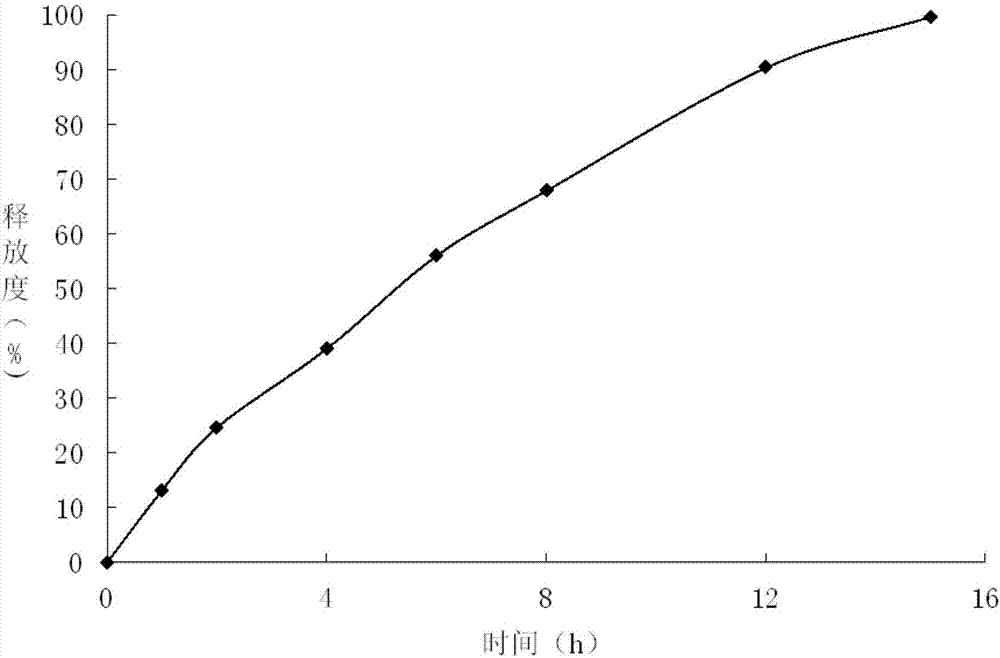

Embodiment 3

[0038] Preparation of Example 3 Gliclazide Sustained-release Tablets

[0039]

[0040]

[0041] Preparation Process:

[0042]①Take glyceryl behenate, heat to 65-70°C to melt, keep warm and add the prescribed amount of meglumine while stirring;

[0043] ②Continue to keep warm at 65-70°C, add gliclazide at the same time, use an electric stirrer to stir for more than 30 minutes until it melts, quickly put it into ice-water mixture to solidify, and put it in a desiccator to dry after it is completely solidified, and the drying temperature is lower than 60 ℃, drying time is 2h, grind, and pass through 80 mesh sieve to obtain drug-loaded granules;

[0044] ③Mix the drug-loaded granules with the prescribed amount of mannitol (passed through a 100-mesh sieve) and magnesium stearate evenly, and press into tablets, Φ9mm punched tablets, and control the hardness within the range of 40-60N.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com