Preparation method of fluorosilicone ultrafine modified glass fiber filter material

A filter material, glass fiber technology, applied in the processing of textile materials, continuous processing of textile materials, equipment configuration of textile materials, etc., can solve the problem of filtration accuracy, acid resistance, corrosion resistance, temperature resistance and wear resistance The problems of poor folding resistance and poor toughness of glass fiber can achieve the effects of long service life, high dust filtering accuracy and outstanding corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

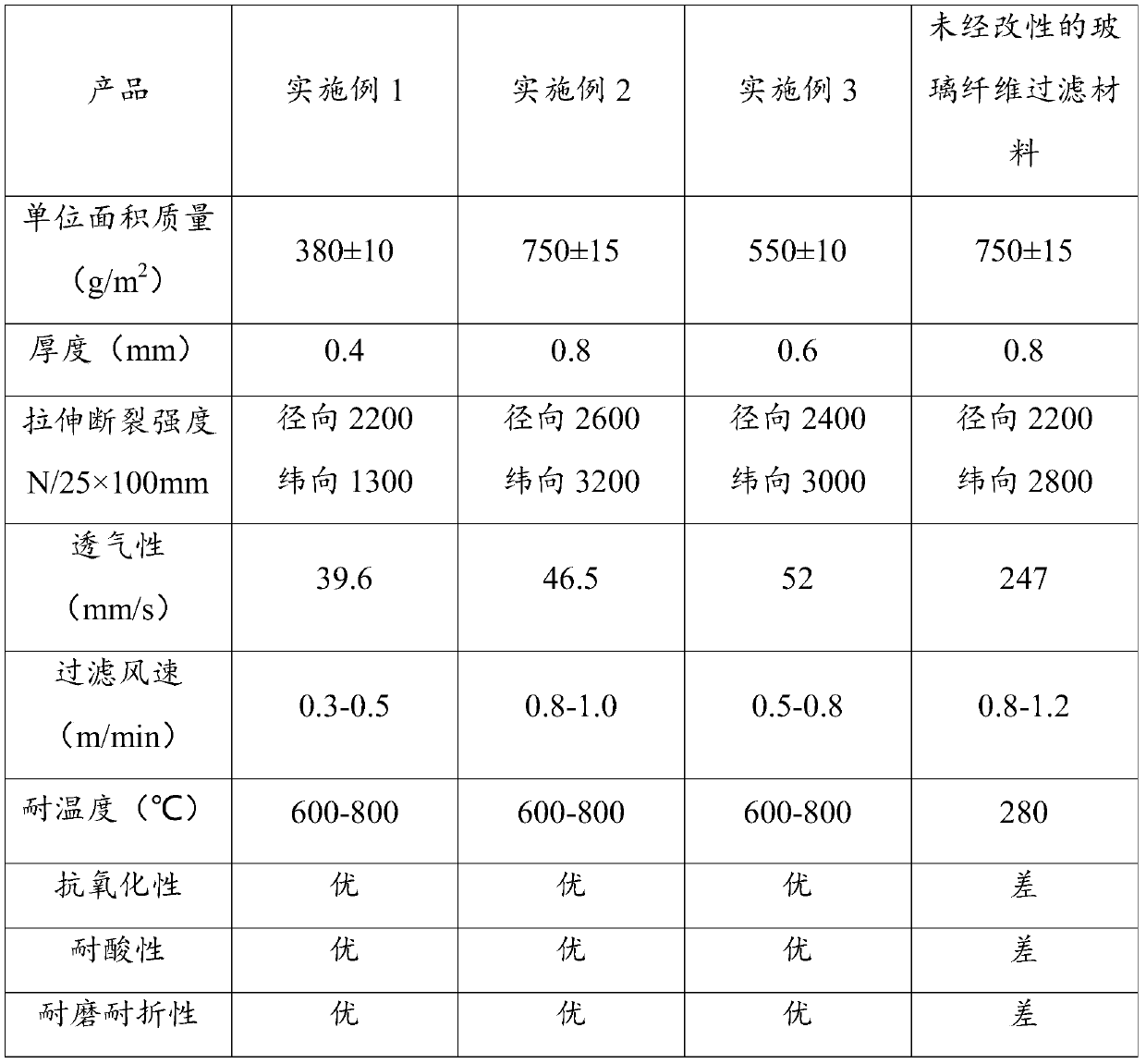

Examples

Embodiment 1

[0031] A preparation method of fluorosilicone ultrafine modified glass fiber filter material is prepared according to the following steps:

[0032] (1) The twisted and untwisted yarns of E-grade glass fibers with a single filament diameter of 3.5 μm are fluffed, warped, and heald through the air texturing machine, and then the cam rapier loom and the air-jet loom are used according to one The fabric structure of the three twills is woven to make a glass fiber filter material;

[0033] (2) Put the filter material in a 9m shaft furnace that has been dried by a hot blast stove, store the cloth back and forth for 30m through the cloth guide roller, and perform thermal cleaning at 500°C. The impurities in each process are removed, and the pure glass fiber is exposed after high-temperature hot cleaning, and the residual amount of wire drawing sizing agent reaches 0.02%;

[0034] (3) Place the hot-cleaned glass fiber filter material in an immersion tank for immersion treatment. The ...

Embodiment 2

[0042] A preparation method of fluorosilicone ultrafine modified glass fiber filter material is prepared according to the following steps:

[0043] (1) The twisted and untwisted yarns of grade E glass fiber with a single filament diameter of 5.5 μm are fluffed, warped, and heald by an air texturing machine, and then the cam rapier loom and air-jet loom are used to follow the twill weft The double fabric structure is woven to make glass fiber filter material;

[0044] (2) Put the filter material in a 9m shaft furnace that has been dried by a hot blast stove, store the cloth back and forth for 30m through the cloth guide roller, and perform thermal cleaning at 550°C. The impurities in each process are removed, and the pure glass fiber is exposed after high-temperature hot cleaning, and the residual amount of wire drawing sizing agent reaches 0.02%;

[0045] (3) Place the hot-cleaned glass fiber filter material in an immersion tank for immersion treatment. The immersion tank is ...

Embodiment 3

[0053] A preparation method of fluorosilicone ultrafine modified glass fiber filter material is prepared according to the following steps:

[0054] (1) The twisted and untwisted yarns of grade E glass fibers with a single filament diameter of 4.0 μm are fluffed, warped, and heald by an air texturing machine, and then the cam rapier loom and air-jet loom are used to follow the twill weft Double satin fabric structure is woven to make glass fiber filter material;

[0055] (2) Put the filter material in a 9m shaft furnace that has been dried by a hot blast stove, store the cloth 30m back and forth through the cloth guide roller, and perform thermal cleaning at 520°C. The impurities in each process are removed, and the pure glass fiber is exposed after high-temperature hot cleaning, and the residual amount of wire drawing sizing agent reaches 0.02%;

[0056] (3) Put the hot-cleaned glass fiber filter material in the dipping tank for dipping treatment. The dipping tank is a white ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com