Preparation method of cerium oxide/graphene quantum dot/graphene-like carbon nitride composite photocatalytic material

A graphene quantum dot, olefin phase carbon nitride technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of photocatalytic activity to be further improved, low utilization rate of solar energy, etc. , to achieve the effects of high synthesis yield and purity, high electron mobility, and cheap and easy-to-obtain raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

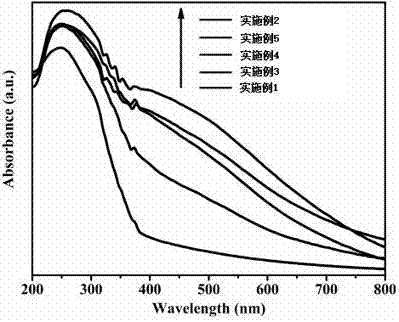

Embodiment 1

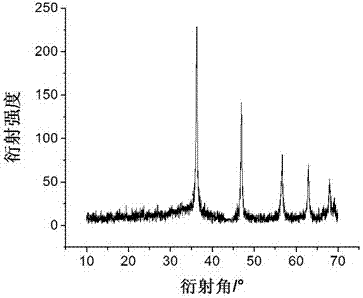

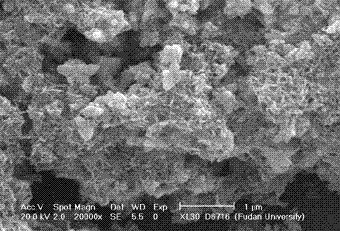

[0021] (1) Weigh 12 grams of melamine and 0.5 g of cerium oxalate, add them to an agate mortar and grind them evenly, then add them into an alumina crucible with a capacity of 25 ml, and put them in a muffle furnace at 610°C for 4 hours to obtain Pale yellow graphene-like carbon nitride embedded with cerium oxide;

[0022] (2) The synthesis of nitrogen-doped graphene quantum dots is as follows: take 0.8 g of citric acid and 0.65 g of urea and dissolve them in 15 ml of deionized water. Keep the temperature in a drying oven for 8 hours, cool to normal temperature to obtain a uniformly dispersed nitrogen-doped graphene quantum dot solution; take 2 milliliters of nitrogen-doped graphene quantum dot solution and disperse it in 30 milliliters of deionized water, and obtain solution A after ultrasonication;

[0023] (3) Dissolve 0.1 g of the graphene-like carbon nitride obtained in step (1) in 10 ml of water, ultrasonicate for 1 hour, then slowly add solution A, and stir for 15 hours...

Embodiment 2

[0026] (1) Weigh 13 grams of melamine and 0.5 g of cerium oxalate, add them to an agate mortar and grind them evenly, then add them to an alumina crucible with a capacity of 25 ml, and put them in a muffle furnace at 660°C for 2 hours to obtain Pale yellow graphene-like carbon nitride embedded with cerium oxide;

[0027] (2) The synthesis of nitrogen-doped graphene quantum dots is as follows: take 0.9 g of citric acid and 0.95 g of urea and dissolve them in 20 ml of deionized water. Keep the temperature in a drying oven for 12 hours, cool to normal temperature to obtain a uniformly dispersed nitrogen-doped graphene quantum dot solution; take 3 milliliters of nitrogen-doped graphene quantum dot solution and disperse it in 30 milliliters of deionized water, and obtain solution A after ultrasonication;

[0028] (3) Dissolve 0.5 g of graphene-like carbon nitride obtained in step (1) in 20 ml of water, ultrasonicate for 5 hours, then slowly add solution A, and stir for 20 hours at ...

Embodiment 3

[0031] (1) Weigh 12 grams of melamine and 0.3 g of cerium oxalate, add them into an agate mortar and grind them evenly, then add them into an alumina crucible with a capacity of 25 ml, and put them in a muffle furnace at 650°C for 3 hours to obtain Pale yellow graphene-like carbon nitride embedded with cerium oxide;

[0032] (2) The synthesis of nitrogen-doped graphene quantum dots is as follows: take 0.8 g of citric acid and 0.7 g of urea and dissolve them in 20 ml of deionized water. Keep the temperature in a drying oven for 10 hours, cool to normal temperature to obtain a uniformly dispersed nitrogen-doped graphene quantum dot solution; take 2 milliliters of nitrogen-doped graphene quantum dot solution and disperse it in 30 milliliters of deionized water, and obtain solution A after ultrasonication;

[0033] (3) Dissolve 0.2 g of the graphene-like carbon nitride obtained in step (1) in 10 ml of water, ultrasonicate for 3 hours, then slowly add solution A, and stir for 15 ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com