a gelling material

A technology of cementitious materials and raw materials, applied in cement production and other directions, can solve the problems of environmental and human hazards, incomplete detoxification, etc., and achieve the effects of large solidification, reduction of diffusion and leaching rate, and obvious effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

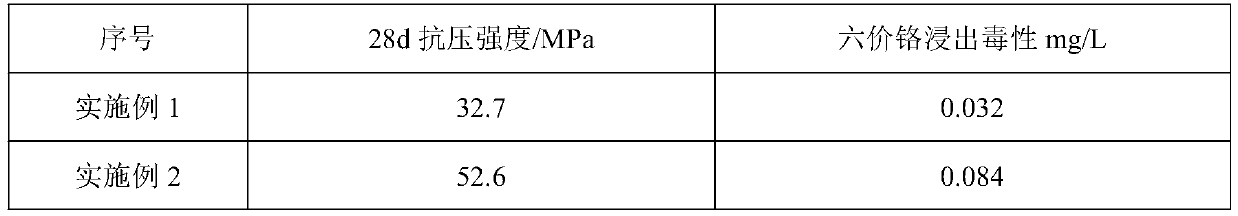

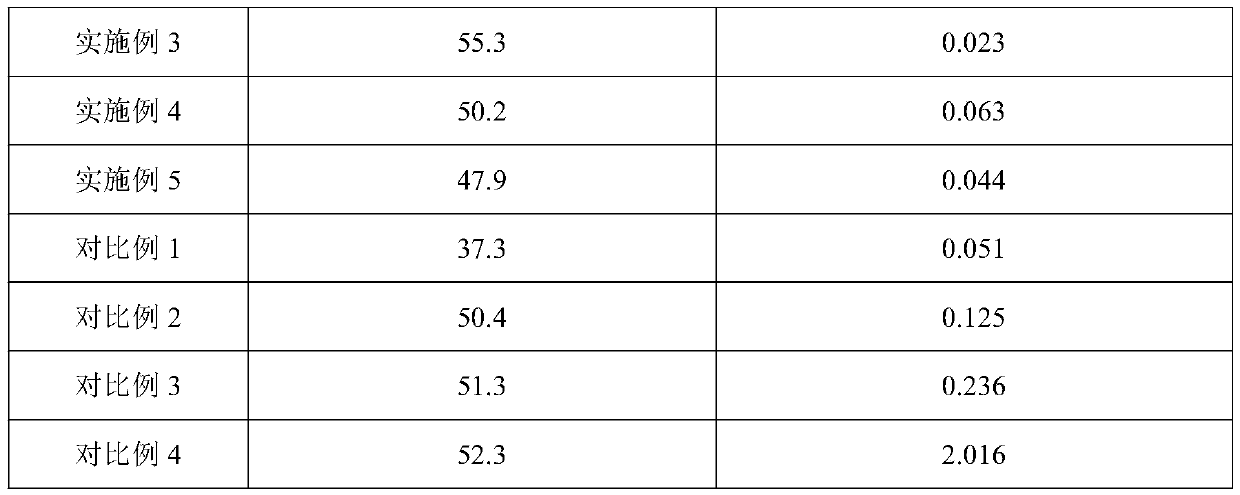

Examples

Embodiment 1

[0029] A cementitious material consisting of the following raw materials in weight fractions: 20 parts of chromium slag, 20 parts of aluminum profile waste slag, 40 parts of slag powder, 5 parts of diatomaceous earth, 1 part of silica fume, 0.5 part of reducing agent, and alkaline activator 3 parts, 0.1 part of complexing agent, 0.01 part of sucrose, 2 parts of water reducing agent.

[0030] The reducing agent is composed of stannous pyrophosphate, sodium pyrosulfite and sodium hypophosphite.

[0031] The basic activator is composed of water glass with a modulus of 1.5, triisopropanolamine and sodium ethylate in a weight ratio of 80:10:1.

[0032] The complexing agent is iminodiacetic acid.

[0033] The water reducer is a powder polycarboxylate water reducer.

Embodiment 2

[0035] A cementitious material consisting of the following raw materials in weight fractions: 30 parts of chrome slag, 15 parts of aluminum profile waste slag, 60 parts of slag powder, 2 parts of diatomite, 3 parts of silica fume, 0.1 part of reducing agent, and alkaline activator 8 parts, 0.05 part of complexing agent, 0.1 part of sucrose, 0.5 part of water reducing agent.

[0036] The reducing agent is composed of sodium metabisulfite and zinc borohydride in a weight ratio of 3:1.

[0037] The basic activator is composed of water glass with a modulus of 1.8, triisopropanolamine and sodium ethylate in a weight ratio of 100:5:1.

[0038] The complexing agent is disodium edetate.

[0039] The water reducer is a powder polycarboxylate water reducer.

Embodiment 3

[0041] A cementitious material consisting of the following raw materials in weight fractions: 27 parts of chromium slag, 16 parts of aluminum profile waste slag, 53 parts of slag powder, 3 parts of diatomaceous earth, 2 parts of silica fume, 0.4 part of reducing agent, and alkaline activator 6 parts, 0.08 parts of complexing agent, 0.06 parts of sucrose, 1.2 parts of water reducing agent.

[0042] The reducing agent is composed of stannous pyrophosphate and dihydroxyacetone in a weight ratio of 6:1.

[0043] The basic activator is composed of water glass with a modulus of 1.6, triisopropanolamine and sodium ethylate in a weight ratio of 100:8:1.

[0044] The complexing agent is disodium edetate.

[0045] The water reducer is a powder polycarboxylate water reducer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com