Preparation method for bio-fertilizer

A bio-fertilizer and microorganism technology, applied in the field of bio-fertilizer preparation, can solve the problems of saline-alkali control soil improvement, salt-tolerant plant varieties, single engineering technology, high cost, and the impact of soil environment needs to be investigated and researched, etc. Micro-ecological environment, improving physical properties, inhibiting activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: preparation bacterial suspension

[0026] According to the characteristics of the bacteria and the promotion or antagonistic effect of the flora, the following strains were selected to prepare the mixed bacterial suspension. See Table 1 for the names of the strains. The strains were purchased from the China Common Microorganism Culture Collection Management Center. body, the specific steps are as follows:

[0027] Step 1.1 Under aseptic operation, use a sterile micropipette to draw 50 μL (or 1-2 drops) of the bacterial solution from the dissolved tube, and drop it into the solid specified medium (the medium number and temperature are shown in the strain order form) ) near a certain edge, inoculated on the culture medium by streaking method;

[0028] Step 1.2 Place the inoculated medium in an incubator at a specified temperature for cultivation;

[0029] Step 1.3 In a sterile environment, wipe the outer tube with cotton dipped in 75% alcohol, and heat the...

Embodiment 2

[0036] Embodiment 2, the acquisition of decomposed matter

[0037] Calculated in parts by weight, take 34-54 parts of solid farmyard manure, add 20-30 parts of fallen leaf compost, 4-6 parts of mushroom mycelium, 2-3 parts of superphosphate or 1.5-2.5 parts of potassium dihydrogen phosphate, water 1-2 portions, mix well, ferment at 60-70°C for 3-4 days to obtain decomposed matter.

Embodiment 3

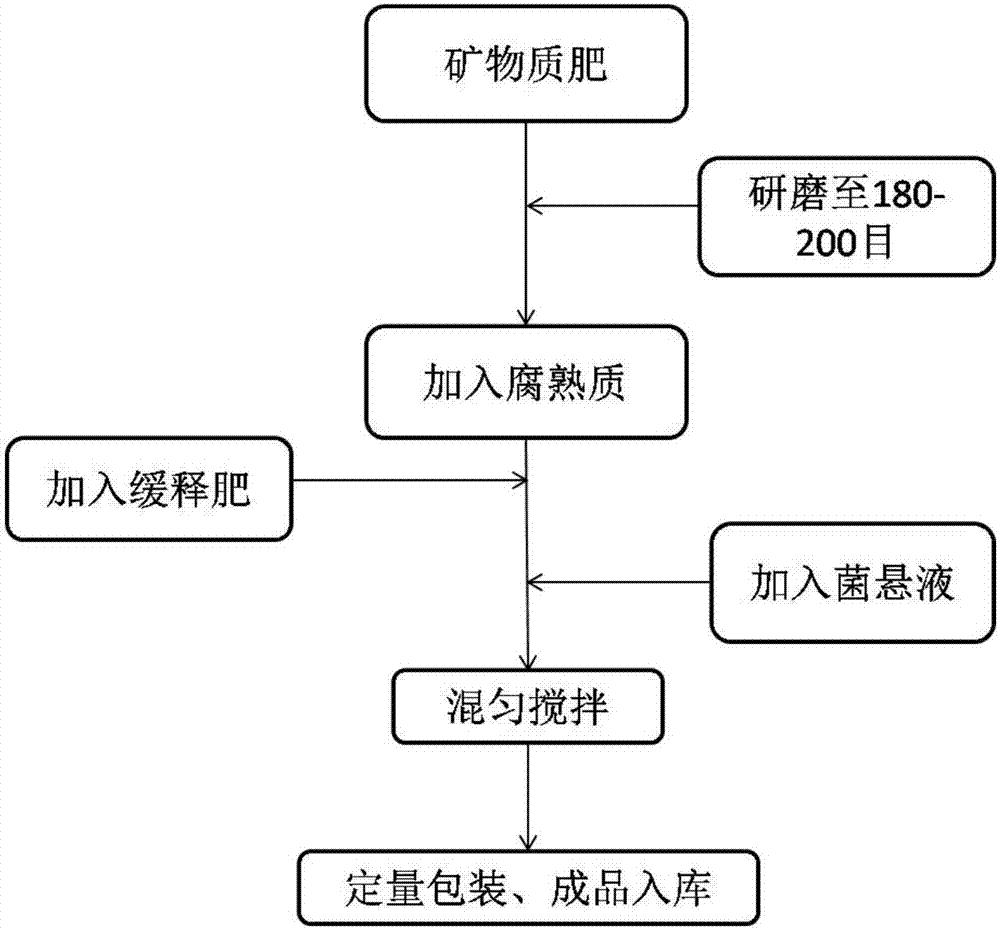

[0038] Embodiment 3, the acquisition of biological fertilizer

[0039] Proceed as follows:

[0040] Step 3.1 Take 10 parts of silicate minerals, 6 parts of calcite, 15-20 parts of pumice, 5-8 parts of potassium feldspar, 9 parts of Phytophthora, 6 parts of sepiolite, 14 parts of vermiculite, 7 parts of serpentine, Grind 6 parts of Hanshui stone into 180-200 mesh powder, mix well to make mineral fertilizer.

[0041] Step 3.2 10 parts of decomposed matter were crushed to 0.5mm.

[0042] Step 3.3 15 parts of superphosphate, 23 parts of urea formaldehyde, 0.5-1 part of ammonium molybdate, 1 part of EDTA-metal chelate, grind into 160-170 mesh powder, and mix to make slow-release fertilizer.

[0043] Step 3.4 Put the mineral fertilizer, decomposed substance and slow-release fertilizer into the blender and stir and mix the fertilizer matrix in proportion.

[0044] Step 3.5 Mix the fertilizer matrix with the bacterial suspension in Example 1 at a ratio of 3:1 to make a biological fer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com