Alkane sensing material, preparation method and use method

A sensing material and alkane technology, applied in the field of chemistry, can solve the problem of being easily interfered by other organic substances, and achieve the effects of easy availability of raw materials, simple raw materials, and mild reaction strips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The preparation process of alkane sensing material mainly includes the following steps:

[0040] Step A: Preparation of methyl hexamethylenediamine formate: 1,6-hexanediamine, liquid dimethyl carbonate and ferrous salt with a molar ratio of 1:1:1 are dissolved in a certain amount of sodium alkoxide with less than four carbon atoms In the solvent, and under the condition of the reaction temperature of 60-70 ℃, carry out the stirring reaction, and control the stirring reaction time for not less than 8h;

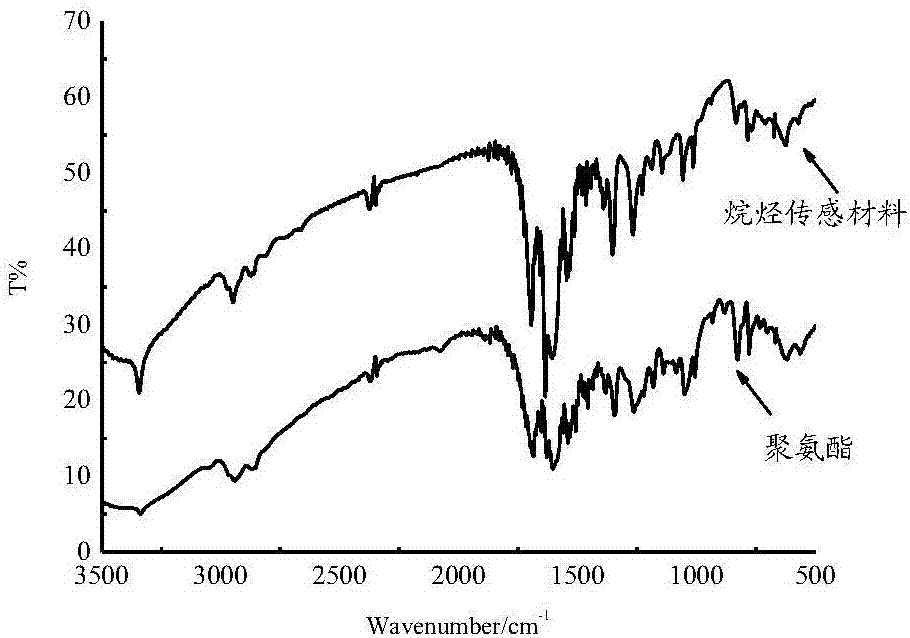

[0041] Step B: Prepare Fe-containing 2+ Polyurethane: the hexamethylenediamine formate obtained above is dissolved in a certain amount of alcohol solvent with four carbon atoms or less, in AlCl 3 ·6H 2 Under the catalysis of O and epoxy resin, the N 2 Or under the protection of an inert gas atmosphere, stir and heat up, and control the reaction temperature not lower than 160°C, and the reaction time is not less than 1.5h;

[0042] Step C: Preparation of alkane sensin...

Embodiment 1

[0049] Step O: Preparation of sodium methoxide: remove the sodium from the kerosene, wipe off the kerosene, put it into methanol solution, and make excess sodium until no bubbles come out and the reaction is complete.

[0050] Step A1: Preparation of methyl hexamethylenediamine formate: put 11.6g of 1,6-hexanediamine in a three-necked flask, add 41.3mL liquid dimethyl carbonate, 0.7g sodium methoxide, 0.9343g FeSO 4 , keeping the temperature at 60-70° C., stirring for 8 hours, cooling the white liquid obtained by the reaction, filtering, and drying to obtain a white solid powder.

[0051] Step B1: Prepare Fe-containing 2+ Polyurethane: Weigh 9.003g of the product obtained in the above step A1 and put it into a 250mL three-necked flask, add 2.89mL of ethylene glycol, and add 0.7488g of AlCl 3 ·6H 2 Under the catalysis of O and 3.31g epoxy resin, N 2 Stir at the same time to raise the temperature, the temperature is kept at about 160°C, and the reaction is completed after 1.5...

Embodiment 2

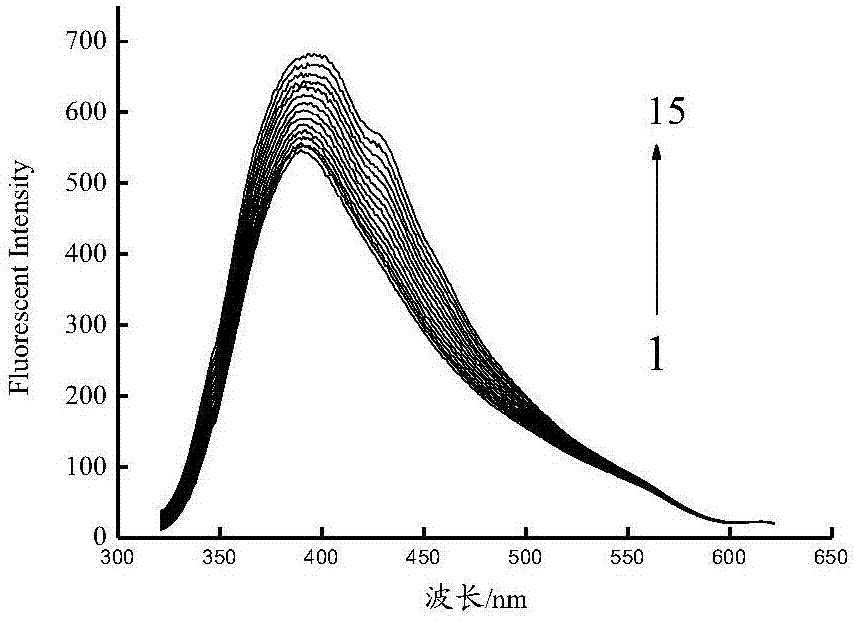

[0076] Embodiment 2: Utilize alkane sensing material to detect n-heptane:

[0077] Step a2: Place the alkane sensing material prepared in Example 1 above on a horizontally cleaned glass substrate, cast it into a film, and put the film together with the glass substrate in an oven at 45°C to dry for 0.5h , to prepare alkane sensing composite membrane;

[0078] Step b2: scanning the ethanol soaked in the alkane sensing composite film in the sample cell by a fluorescence spectrophotometer to obtain a corresponding blank fluorescence spectrum;

[0079] Step c2: scan the n-heptane solutions of different concentrations immersed in the alkane sensing composite membrane in the sample pool by a fluorescence spectrophotometer, and obtain the sample fluorescence spectra corresponding to the concentrations of the n-heptane solutions;

[0080] Step d2: By comparing the blank fluorescence spectrum obtained in step b2 with the sample fluorescence spectrum obtained in step c2, it can be seen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com