CuCo2S4 active substance diluent for super-capacitor and preparation method thereof

An active material and supercapacitor technology, which is applied to the CuCo2S4 active material diluent of supercapacitors and its preparation field, can solve the problems of large nanocrystal particles and uneven dispersion, and achieve high dispersion, good stability, and high specific capacitance activity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

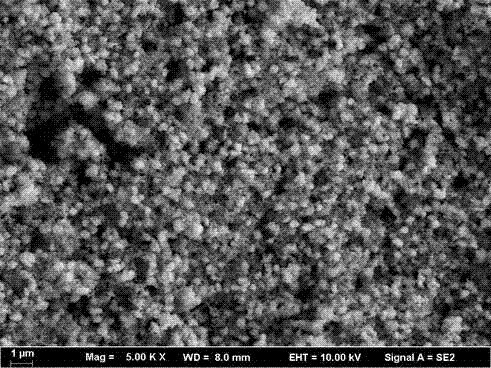

Image

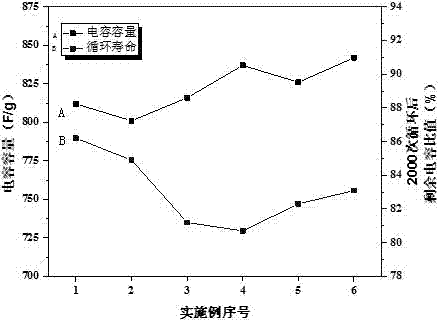

Examples

preparation example Construction

[0025] The present invention is used for the CuCo of supercapacitor 2 S 4 A preparation method for an active substance dilution, the preparation method comprising the following steps:

[0026] (1) Add copper source and cobalt source into glycerol at a molar ratio of 1:2. The amount of glycerol is 20 to 25 times the total mass of copper source and cobalt source. Stir quickly until the copper source and cobalt source until completely dissolved in glycerin;

[0027] (2) Weigh the sulfur source according to the molar ratio of copper source, cobalt source, and sulfur source as 1:2:4, and slowly add deionized water to the sulfur source, stirring while dropping until the sulfur source is completely dissolved;

[0028] (3) Mix the solutions obtained in the previous two steps, and stir for 10-20 minutes to disperse the ions evenly, then pour them into a high-pressure reactor and seal;

[0029] (4) Place the autoclave in an oven at 175-190°C for 10-15 hours and take it out. After it ...

Embodiment 1

[0034] This example is used to prepare CuCo 2 S 4 The copper source, cobalt source, and sulfur source of the active material are: copper chloride, cobalt chloride, and thiourea; CuCo for supercapacitors 2 S 4 The preparation method of active substance dilution comprises the following steps:

[0035] Step 1, add copper source and cobalt source into glycerol according to the molar ratio of 1:2, the amount of glycerol is 20 times of the total mass of copper source and cobalt source, stir quickly until the copper source and cobalt source are completely until dissolved in glycerol;

[0036] In the second step, the sulfur source is weighed according to the molar ratio of copper source, cobalt source, and sulfur source as 1:2:4, and deionized water is slowly added dropwise to the sulfur source, and stirred while dropping until the sulfur source is completely dissolved;

[0037] Step 3: Mix the solutions obtained in the previous two steps, and stir for 15 minutes to disperse the i...

Embodiment 2

[0041] This example is used to prepare CuCo 2 S 4 The copper source, cobalt source, and sulfur source of the active material are: copper sulfate, cobalt nitrate, thiourea, CuCo for supercapacitors 2 S 4 The preparation method of active substance dilution comprises the following steps:

[0042] In the first step, the copper source and the cobalt source are added into the glycerol according to the molar ratio of 1:2, and the amount of the glycerol is 23 times of the total mass of the copper source and the cobalt source, stirring rapidly until the copper source and the cobalt source are completely until dissolved in glycerol;

[0043] In the second step, the sulfur source is weighed according to the molar ratio of copper source, cobalt source, and sulfur source as 1:2:4, and deionized water is slowly added dropwise to the sulfur source, and stirred while dropping until the sulfur source is completely dissolved;

[0044] Step 3: Mix the solutions obtained in the previous two s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com