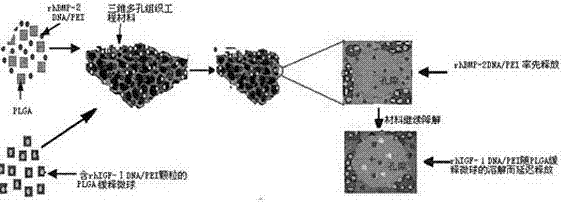

Preparation method of double-gene time sequence sustained-release tissue engineering scaffold material

A tissue engineering scaffold, dual-gene technology, applied in gene therapy, pharmaceutical formulations, genetic material management system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Step 1: Through plasmid construction and amplification, 0.1g rhBMP-2 and 0.1g rhIGF-I are obtained.

[0032] Step 2. Preparation of rhBMP-2DNA / polyacetimide nanoparticles:

[0033] a. Mix 0.1grhBMP-2DNA and 30g polyethylene oxide uniformly to obtain a drug mixture,

[0034] b. Dissolve the drug mixture in 50mL N,N-dimethylformamide to obtain a drug oil solution;

[0035] c. Add the drug oil solution to 90g of a polyacetimide ethanol solution with a mass concentration of 60% and a weight average molecular weight of 1000 and continue to stir for 30 minutes;

[0036] d. Add 40g sucrose and lyophilize for later use.

[0037] Step 3. Preparation of rhIGF-Ⅰ DNA / polyacetimide nanoparticles;

[0038] a. Mix 0.1g rhIGF-I and 30g erythritol uniformly to obtain a drug mixture,

[0039] b. Dissolve the drug mixture in 50 mL of tetrahydrofuran to obtain a drug oil solution;

[0040] c. Add the drug oil solution to 90 g of a polyacetimide ethanol solution with a mass concentration of 60% and a wei...

Embodiment 2

[0049] Step 1: Through plasmid construction and amplification, 0.1g rhBMP-2 and 0.1g rhIGF-I are obtained.

[0050] Step 2. Preparation of rhBMP-2DNA / polyacetimide nanoparticles;

[0051] a. Mix 0.1grhBMP-2DNA and 30g polypyrrolidone uniformly to obtain a drug mixture,

[0052] b. Dissolve the drug mixture in 50 mL of thionyl chloride to obtain a drug oil solution;

[0053] c. Add the drug oil solution to 90 g of a polyacetimide solution with a mass concentration of 60% and a weight average molecular weight of 3500 and continue to stir for 40 minutes;

[0054] d. Add 40g of sucrose and freeze-dry it for later use;

[0055] Step 3. Preparation of rhIGF-Ⅰ DNA / polyacetimide nanoparticles;

[0056] a. Mix 0.1g rhIGF-I and 30g pharmaceutical excipient polyethylene oxide uniformly to obtain a drug mixture,

[0057] b. Dissolve the drug mixture in 50 mL of organic solvent ethyl acetate to obtain a drug oil solution;

[0058] c. Add the drug oil solution to 90g of a polyacetimide solution with a ma...

Embodiment 3

[0067] Step 1: Through plasmid construction and amplification, 0.1g rhBMP-2 and 0.1g rhIGF-I are obtained.

[0068] Step 2. Preparation of rhBMP-2DNA / polyacetimide nanoparticles;

[0069] a. Mix 0.1grhBMP-2DNA and 30g erythritol as a pharmaceutical excipient to obtain a drug mixture.

[0070] b. Dissolve the drug mixture in 50 mL of organic solvent thionyl chloride to obtain a drug oil solution;

[0071] c. Add the drug oil solution to 90 g of a polyacetimide solution with a mass concentration of 60% and a weight average molecular weight of 9000 and continue to stir for 50 minutes;

[0072] d. Add 40g of sucrose and freeze-dry it for later use;

[0073] Step 3. Preparation of rhIGF-Ⅰ DNA / polyacetimide nanoparticles;

[0074] a. Mix 0.1g rhIGF-I and 30g polyethylene oxide uniformly to obtain a drug mixture,

[0075] b. Dissolve the drug mixture in 50mL N,N-dimethylformamide to obtain a drug oil solution;

[0076] c. Add the drug oil solution to 90 g of a polyacetimide solution with a mass co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com