Method for preparing fluorescent tungsten oxide quantum dot through solvothermal process, prepared fluorescent tungsten oxide quantum dot and application of fluorescent tungsten oxide quantum dot

A technology of tungsten oxide quantum dots and solvothermal method, which is applied in the field of nanomaterials, can solve the problems of expensive experimental equipment, time-consuming preparation process, and poor performance of tungsten oxide quantum dots, achieving less time-consuming, good dispersion, and easy operation. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Weigh 45mg of tungsten disulfide powder, disperse in 45mL of absolute ethanol, add 0.8mL of hydrogen peroxide to the dispersion, and stir evenly with a glass rod. The prepared mixed solution was transferred to a 100mL reactor, sealed and reacted in an oven with a temperature of 180°C and a reaction time of 20h, and cooled naturally to room temperature. The reacted solution was vacuum filtered through a filter membrane with a pore size of 0.22 μm to remove unreacted residual particles, and the filtrate was collected. Put the filtrate into a dialysis bag with a molecular weight cut off of 1000D and dialyze for 2 to 3 days. The obtained dialysate was frozen and then freeze-dried at a temperature of -20° C. and an air pressure of 20 Pa to obtain tungsten oxide quantum dot powder.

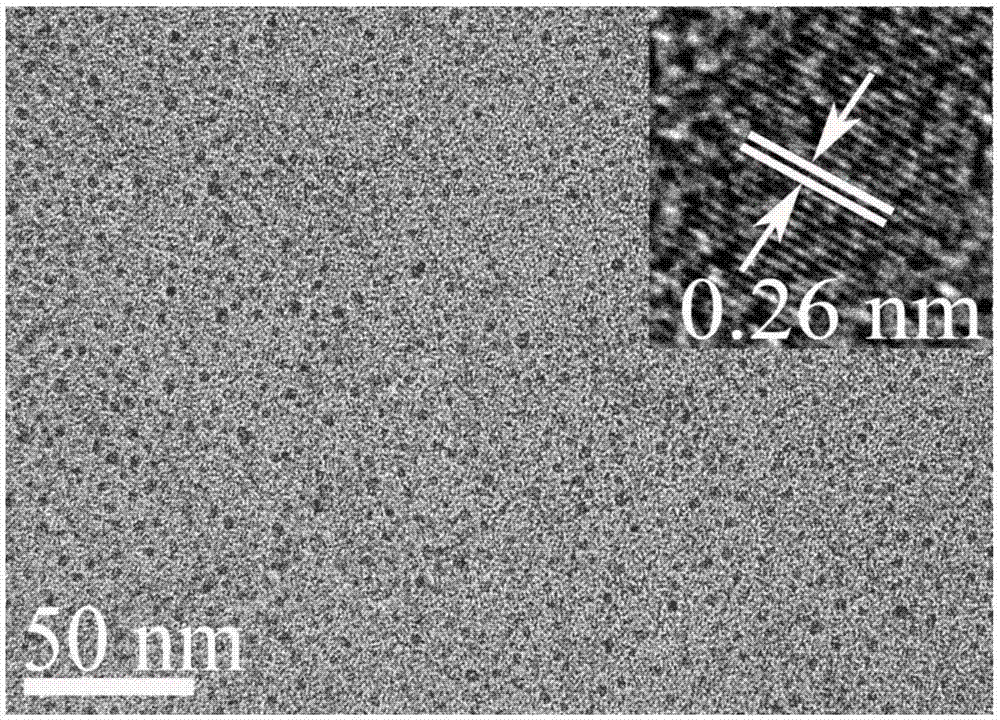

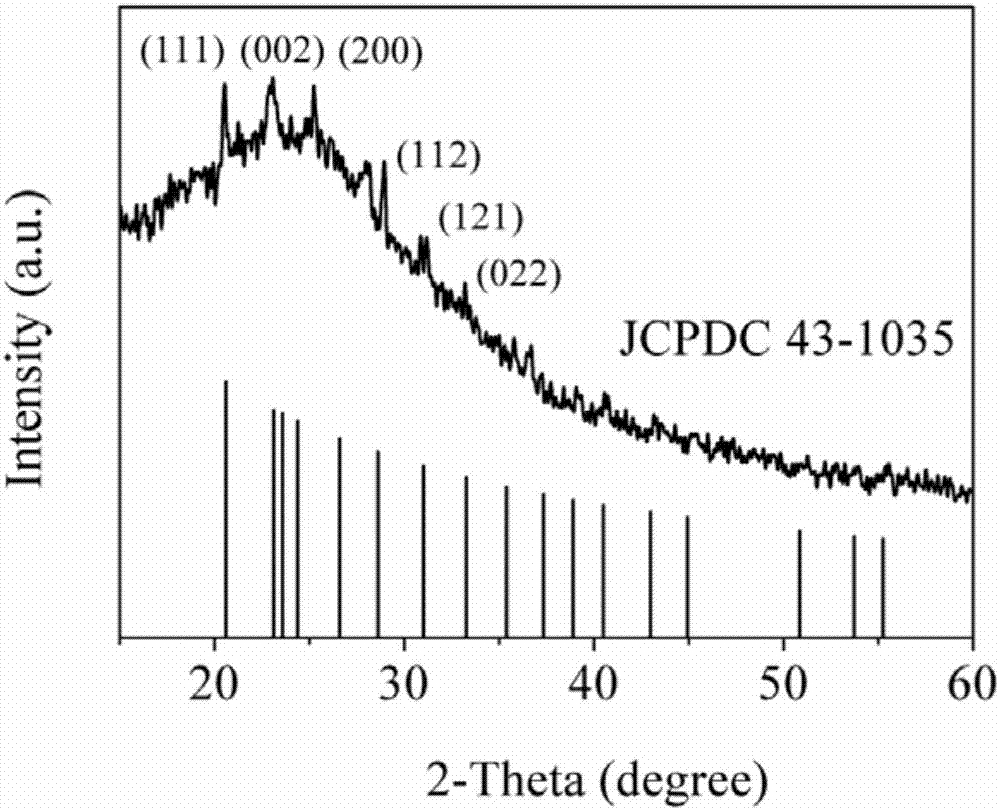

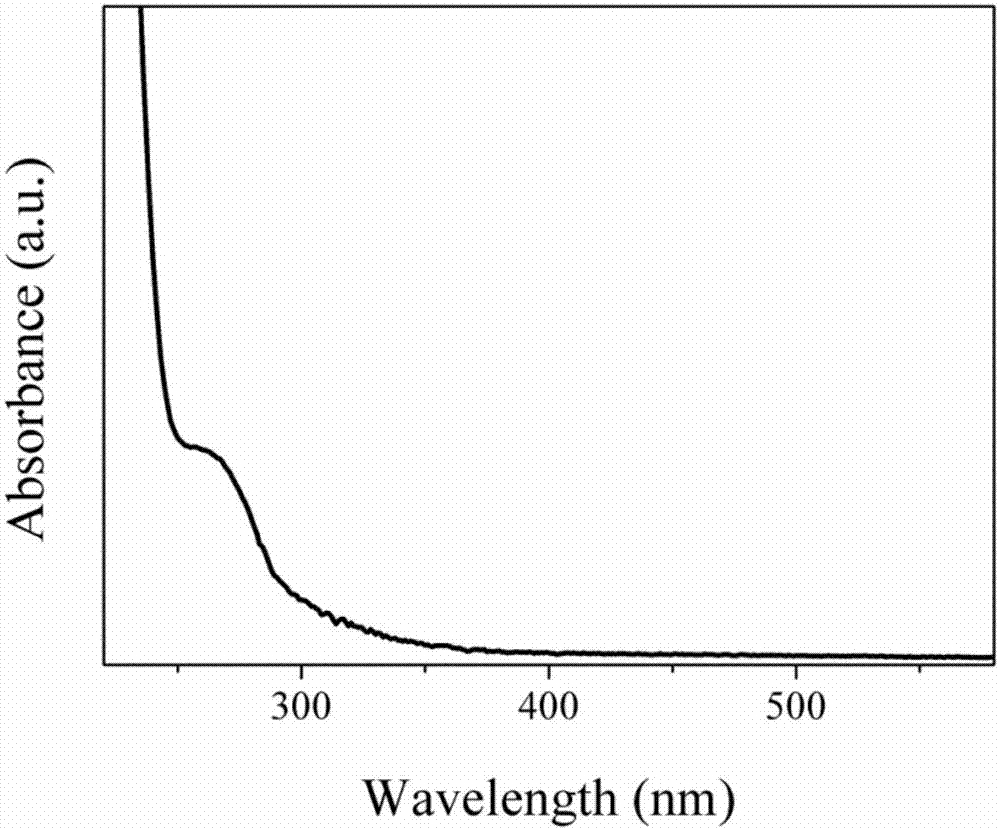

[0038] figure 1 It is a transmission electron microscope picture of the tungsten oxide quantum dot obtained in Example 1. It can be clearly seen that the size distribution of the nanoscale tung...

Embodiment 2

[0040] Weigh 30mg of tungsten disulfide powder, disperse in 45mL of absolute ethanol, add 0.1mL of hydrogen peroxide to the dispersion, and stir evenly with a glass rod. The prepared mixed solution was transferred to a 100mL reactor, sealed and reacted in an oven at a temperature of 60°C and a reaction time of 4h, and cooled naturally to room temperature. The reacted solution was vacuum filtered through a filter membrane with a pore size of 0.22 μm to remove unreacted residual particles, and the filtrate was collected. Put the filtrate into a dialysis bag with a molecular weight cut off of 1000D and dialyze for 2 to 3 days. The obtained dialysate was frozen and then freeze-dried under the conditions of temperature at -20° C. and air pressure at 20 Pa to obtain tungsten oxide quantum dot powder.

Embodiment 3

[0042]Weigh 30mg of tungsten disulfide powder, disperse in 15mL of absolute ethanol, add 0.2mL of hydrogen peroxide to the dispersion, and stir evenly with a glass rod. The prepared mixed solution was transferred to a 100mL reactor, sealed and reacted in an oven at a temperature of 90°C for a reaction time of 8 hours, and cooled naturally to room temperature. The reacted solution was vacuum filtered through a filter membrane with a pore size of 0.22 μm to remove unreacted residual particles, and the filtrate was collected. Put the filtrate into a dialysis bag with a molecular weight cut off of 1000D and dialyze for 2 to 3 days. The obtained dialysate was frozen and then freeze-dried under the conditions of temperature at -20° C. and air pressure at 20 Pa to obtain tungsten oxide quantum dot powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com