Method for preparing ammonium perrhenate through efficient enrichment of rhenium

An ammonium perrhenate enrichment technology, which is applied in the direction of improving process efficiency, can solve the problems of poor quality ammonium perrhenate, low metal recovery rate, and low production efficiency, and achieves technical indicators that are easy to control and metal recovery rate High, high production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

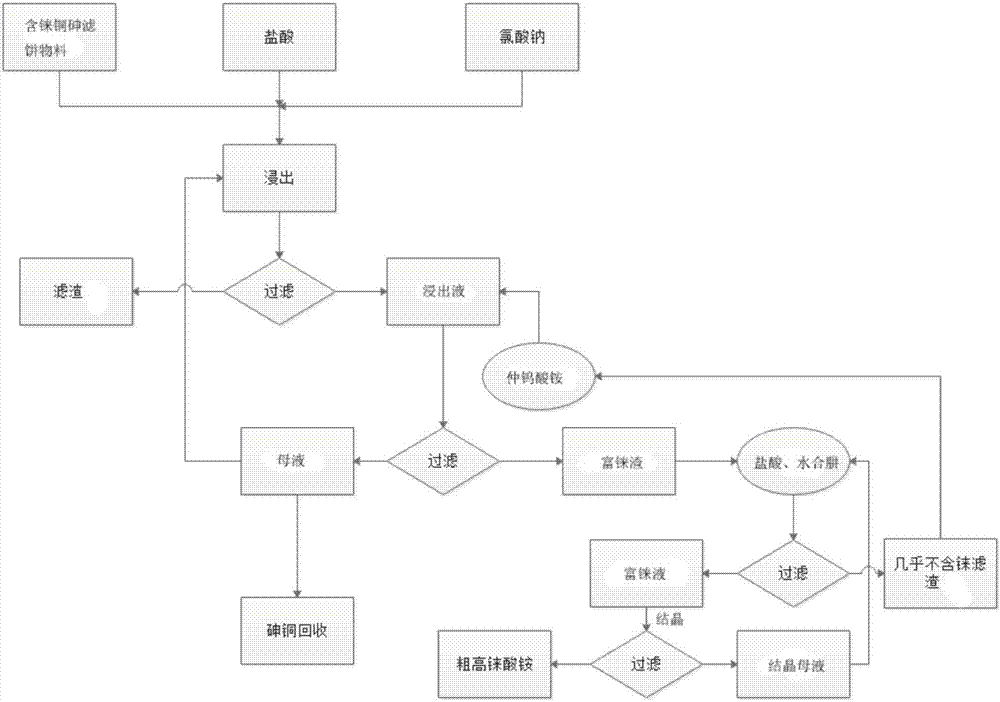

Image

Examples

Embodiment 1

[0022] Embodiment 1, a method for efficiently enriching rhenium to prepare ammonium perrhenate comprises the following steps:

[0023] The first step, leaching of rhenium-copper-arsenic filter cake material

[0024] Take the rhenium-copper-arsenic filter cake and put it into the 4N hydrochloric acid system at a liquid-solid weight ratio of 2.5:1 and add sodium chlorate in batches. The amount of sodium chlorate is 5% of the weight of the rhenium-copper-arsenic filter cake material, stir, and heat up To 90°C, the reaction time is 2.5h, filter the filter residue and leachate, the leachate contains rhenium 400mg / L~500mg / L;

[0025] The second step, precipitation and enrichment of rhenium

[0026] Add ammonium paratungstate to the leaching solution described in the first step, the amount of ammonium paratungstate is 30% of the weight of the rhenium-containing copper-arsenic filter cake material, stir for 5 minutes and filter, the obtained mother liquor contains rhenium 30mg / L~40mg...

Embodiment 2

[0031] Embodiment 2, a method for efficiently enriching rhenium to prepare ammonium perrhenate, comprising the following steps:

[0032] The first step, leaching of rhenium-copper-arsenic filter cake material

[0033] Take the rhenium-copper-arsenic filter cake and put it into the 4N hydrochloric acid system according to the liquid-solid weight ratio of 2.8:1, and add sodium chlorate in batches. The amount of sodium chlorate is 6% of the weight of the rhenium-copper-arsenic filter cake material, stir, and heat up To 90°C, the reaction time is 2.5h, filter the filter residue and leachate, the leachate contains rhenium 400mg / L~500mg / L;

[0034] The second step, precipitation and enrichment of rhenium

[0035] Add ammonium paratungstate to the leaching solution described in the first step. The amount of ammonium paratungstate is 28% of the weight of the rhenium-containing copper-arsenic filter cake material. Stir for 5 minutes and filter. into the slag phase to obtain rhenium-r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com