Loaded quaternary ammonium salt and metal chloride catalyst and preparation method thereof

A quaternary ammonium salt and catalyst technology, which is applied in the field of supported quaternary ammonium salt and metal chloride catalysts and their preparation, can solve the problems of low activity of non-precious metal catalysts, high cost of gold and precious metal catalysts, easy deactivation and loss of mercury catalysts, etc. Achieve the effect of reducing carbon deposition and coking, low cost and less by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1: Weigh 1.05g of copper chloride and 2g of tetrabutylammonium chloride, dissolve them in 10mL of water, let stand at 90°C for 2h, and then filter and separate to obtain the complex; Dissolve the material in 10mL of water until it is completely dissolved to obtain a catalyst impregnation solution. Add 5g of porous coal-based activated carbon carrier to the above catalyst impregnation solution under stirring, and impregnate it in a 60°C oven for 10h. Finally, the sample is dried in a 120°C oven for 12h. Activated carbon supported quaternary ammonium salt and metal chloride catalysts were prepared.

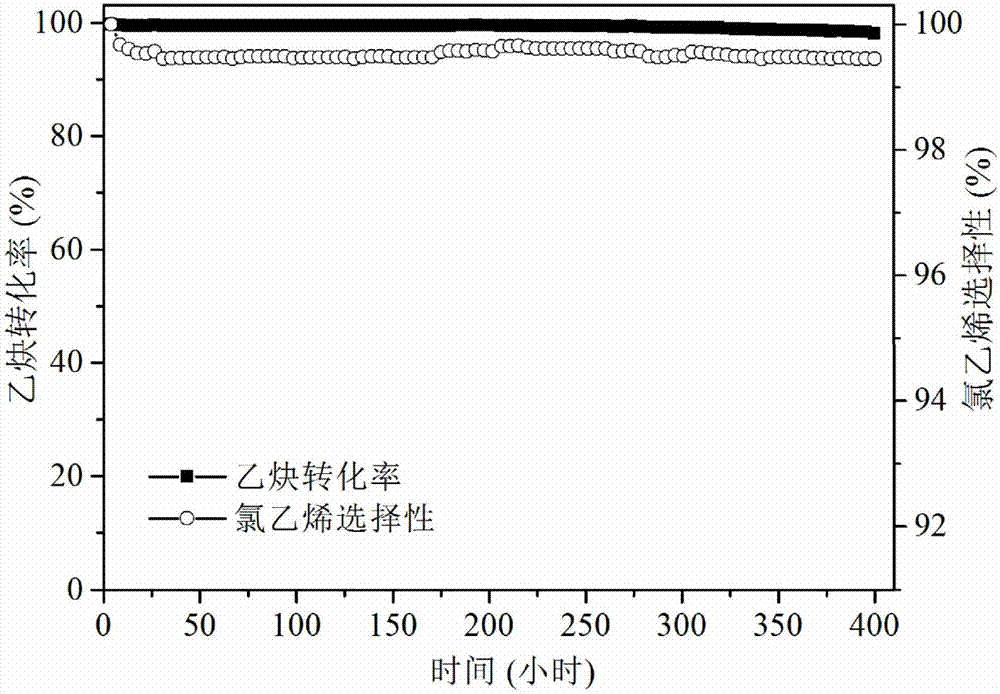

[0030] The catalyst prepared above was placed in a fixed bed reactor for activity, selectivity and stability evaluation, wherein the reaction conditions were reaction temperature 140°C, hydrogen chloride and acetylene molar ratio of 1.5:1, acetylene space velocity of 180h -1 , the acetylene conversion rate of the catalyst is 60.8%, the selectivity is greater than 99.4...

Embodiment 2

[0031] Example 2: Weigh 0.61g of bismuth chloride and 0.05g of 2-hydroxyethyltrimethylammonium chloride, dissolve them in 10mL of ethanol, let stand at 60°C for 10h, and then filter and separate to obtain the complex; adopt equal volume impregnation method , Dissolve the complex obtained above in 10 mL of water until completely dissolved to obtain a catalyst impregnation solution, add 5 g of porous wood activated carbon carrier to the above catalyst impregnation solution under stirring, soak in an oven at 60 °C for 24 h, and finally, the sample is heated at 60 °C After drying in an oven for 12 hours, the activated carbon-supported quaternary ammonium salt and metal chloride catalyst is prepared.

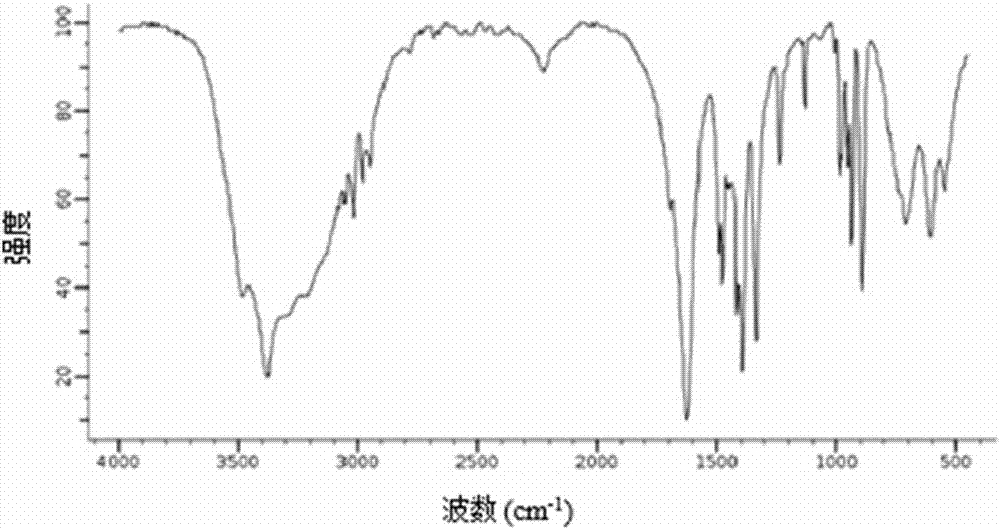

[0032] The obtained catalyst of above-mentioned preparation is done infrared characterization, and infrared spectrogram is as attached figure 1 shown at 1050cm -1There are characteristic peaks of C-N stretching vibration; at 1460cm -1 and 1380cm -1 There are stretching vibration c...

Embodiment 3

[0034] Example 3: Weigh 0.88g of cobalt chloride and 1g of betaine hydrochloride, dissolve them in 10mL of acetonitrile, let stand at 30°C for 12h, and then filter and separate to obtain the complex; The obtained complex was dissolved in 10mL of water until completely dissolved to obtain a catalyst impregnation solution; 5g of porous coconut shell activated carbon carrier was added to the above catalyst impregnation solution under stirring, and immersed in an oven at 40°C for 12h, and finally, the sample was dried in an oven at 100°C After 12 hours, the activated carbon supported quaternary ammonium salt and metal chloride catalyst were prepared.

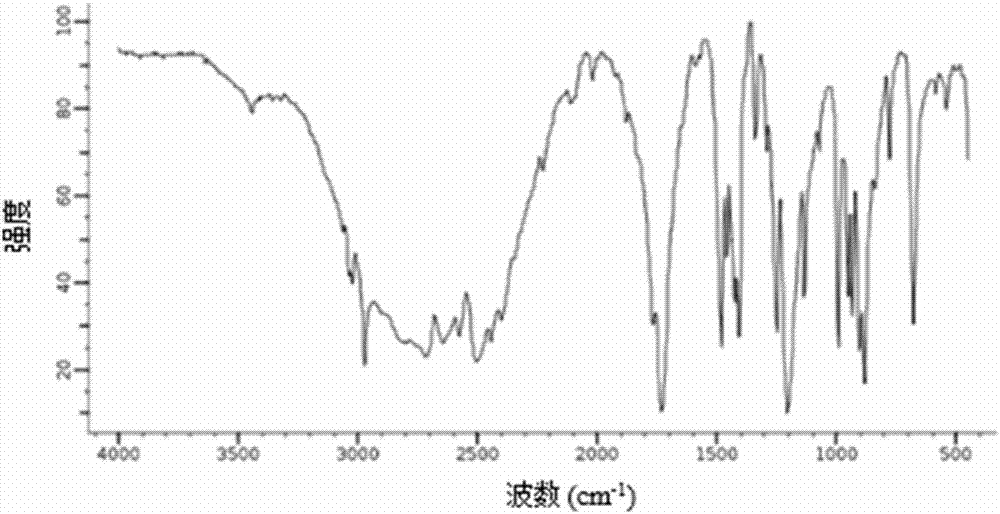

[0035] The obtained catalyst of above-mentioned preparation is done infrared characterization, and infrared spectrogram is as attached figure 2 shown at 1050cm -1 There are characteristic peaks of C-N stretching vibration; at 1460cm -1 and 1380cm -1 There is a characteristic peak of the stretching vibration of the alkyl chain C-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com