Preparation method of antibacterial active carbon

A technology of activated carbon and preparation steps is applied in the field of preparation of bacteriostatic activated carbon, which can solve the problems of bacterial growth and poor bacteriostatic properties, and achieve the effect of reducing the growth of bacteria.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

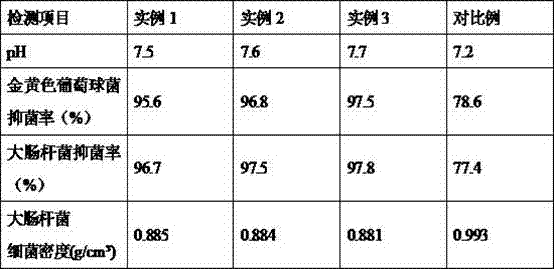

Examples

specific Embodiment approach

[0020] Weigh 600-800g of rice husks, wash them with water for 3-5 times, heat them in an oven to 90-110°C, and dry them for 8-10 hours to obtain dried and cleaned rice husks; weigh 400-500g of perilla leaves, Put the perilla leaves in a mortar and grind for 2-3 hours, filter and remove the filter residue to obtain the filtrate, put the filtrate in a separatory funnel, add dichloroethane 2-4 times the volume of the filtrate into the separatory funnel, wash and extract with water for 3-3 hours 5 times, finally separated to obtain the lower layer liquid, put the lower layer liquid into a rotary evaporator, and rotate at a speed of 70-80r / min at 50-60°C to constant weight to obtain perilla extract powder; ZnCl with a concentration of 5.0mol / L 2 Solution and CuCl with a concentration of 0.4mol / L 2 The solution is mixed as a composite activator, and the dried and cleaned rice husk is mixed with the composite activator at a mass ratio of 1:5, and soaked for 16-18 hours to obtain the...

example 1

[0022] Weigh 600g of rice husks, wash them with water for 3 times, heat them in an oven to 90°C, and dry them for 8 hours to obtain dried and washed rice husks; weigh 400g of perilla leaves and grind them in a mortar for 2 hours , filter and remove the filter residue to obtain the filtrate, put the filtrate in a separatory funnel, add dichloroethane with 2 times the volume of the filtrate to the separatory funnel, wash and extract 3 times, finally separate the lower layer liquid, put the lower layer liquid into the rotary evaporation Rotary evaporation at 50°C at a speed of 70r / min to constant weight in the instrument, to obtain perilla extract powder; ZnCl with a concentration of 5.0mol / L 2 Solution and CuCl with a concentration of 0.4mol / L 2 The solution is mixed as a composite activator, and the dried and cleaned rice husk is mixed with the composite activator at a mass ratio of 1:5, and soaked for 16 hours to obtain the soaked raw material; the soaked raw material is place...

example 2

[0024] Weigh 700g of rice husks, wash them with water for 4 times, heat them in an oven to 100°C, and dry them for 9 hours to obtain dried and washed rice husks; weigh 450g of perilla leaves and grind them in a mortar for 2.5 h, filter and remove the filter residue to obtain the filtrate, place the filtrate in a separatory funnel, add dichloroethane that is 3 times the volume of the filtrate in the separatory funnel, wash and extract 4 times, and finally separate the lower layer liquid, put the lower layer liquid into the rotating In the evaporator, rotate at 55°C at a speed of 75r / min to constant weight to obtain perilla extract powder; ZnCl with a concentration of 5.0mol / L 2 Solution and CuCl with a concentration of 0.4mol / L 2 The solution is mixed as a composite activator, and the dried and cleaned rice husk is mixed with the composite activator at a mass ratio of 1:5, and soaked for 17 hours to obtain the soaked raw material; the soaked raw material is placed in a high-tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com