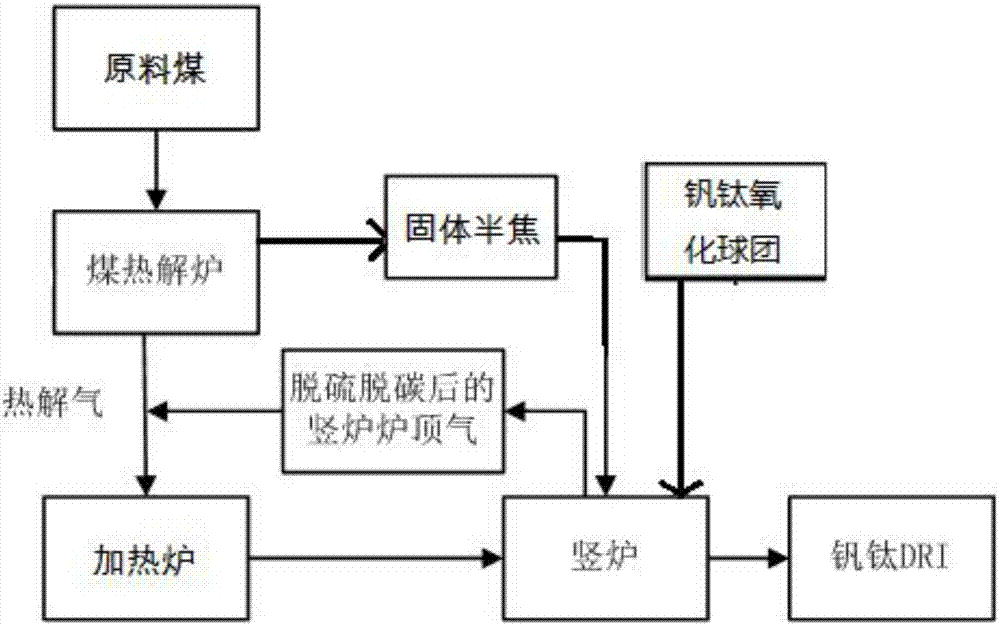

Method and system for reducing schreyerite through coal pyrolysis gas

A coal pyrolysis, vanadium-titanium ore technology, applied in the furnace type, furnace, shaft furnace and other directions, can solve the problems of increasing compressor investment, energy consumption waste, affecting the smooth running of furnace conditions, etc., to reduce water and electricity consumption, reduce production equipment, The effect of reducing the amount of equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

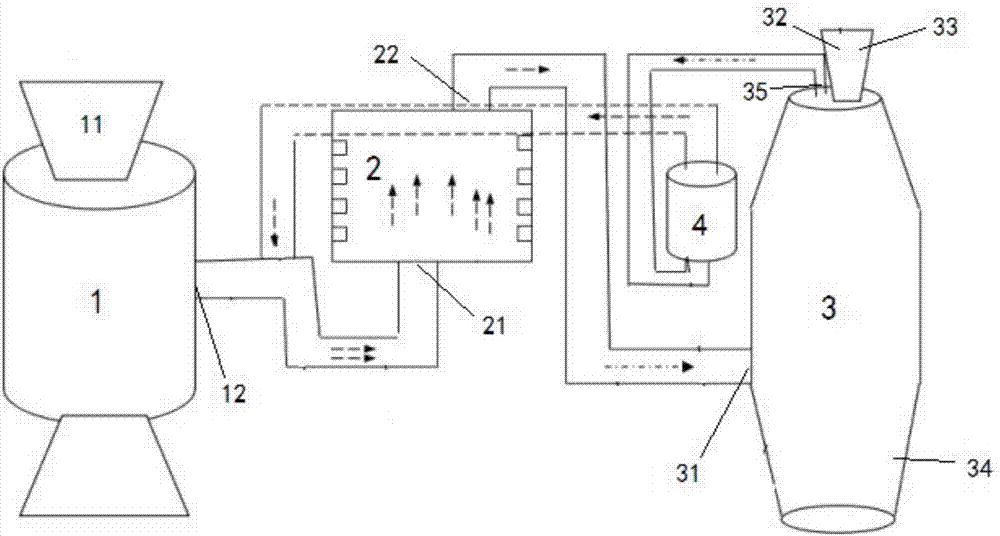

Method used

Image

Examples

Embodiment 1

[0078] Crush the raw coal to a particle size of less than 5mm, and transport it to the top silo of the coal pyrolysis furnace for use, and transport the vanadium-titanium oxide pellets and semi-coke made of vanadium-titanium ore to the top silo of the shaft furnace for use, and the vanadium-titanium oxide balls Group: semi-coke = 100:10, vanadium-titanium oxide pellets, semi-coke main components and contents are shown in Table 1 and Table 2, and the gas heating furnace is heated by a ceramic radiant tube.

[0079] Table 1 Main components and content (%) of vanadium-titanium oxide pellets

[0080] Element

TF

FeO

Fe 2 o 3

V 2 o 5

TiO 2

content

57.12

23.09

55.15

0.65

15.77

[0081] Table 2 Semi-coke main components and content (%)

[0082] Element

C

Vad

Aad

mad

content

67.8

7.55

23.76

0.89

[0083] The raw coal is continuously fed from the top of the coal pyrolysis ...

Embodiment 2

[0090]Crush the raw coal to a particle size of less than 5mm, and transport it to the top silo of the coal pyrolysis furnace for use, and transport the vanadium-titanium oxide pellets and semi-coke made of vanadium-titanium ore to the top silo of the shaft furnace for use, and the vanadium-titanium oxide balls Pellet: semi-coke = 100:8, the main components and content of vanadium-titanium oxide pellets and semi-coke are shown in Table 1 and Table 5, and the gas heating furnace is heated by a ceramic radiant tube.

[0091] Table 5 Main components and content of semi-coke (%)

[0092] Element

C

Vad

Aad

mad

content

64.3

8.55

26.11

0.88

[0093] The raw coal is continuously fed from the top of the coal pyrolysis furnace through the feeding screw, the coal powder stays in the furnace for 1.5s, and is pyrolyzed during the downward process of the pulverized coal in the pyrolysis device to generate solid semi-coke and pyrolysis gas, semi...

Embodiment 3

[0100] Crush the raw coal to a particle size of less than 5mm, and transport it to the top silo of the coal pyrolysis furnace for use, and transport the vanadium-titanium oxide pellets and semi-coke made of vanadium-titanium ore to the top silo of the shaft furnace for use, and the vanadium-titanium oxide balls Group: semi-coke = 100:15, vanadium-titanium oxide pellets, semi-coke main components and contents are shown in Table 1 and Table 8, and the gas heating furnace is heated by a ceramic radiant tube.

[0101] Table 8 Semi-coke main components and content (%)

[0102] Element

C

Vad

Aad

mad

content

66.2

8.33

24.17

0.89

[0103] The raw coal is continuously fed from the top of the coal pyrolysis furnace through the feeding screw, the coal powder stays in the furnace for 1.5s, and is pyrolyzed during the downward process of the pulverized coal in the pyrolysis device to generate solid semi-coke and pyrolysis gas, semi-coke , Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com