Method for preparing ultrafine silver powder

A technology of ultra-fine silver and silver nitrate, which is applied in the field of preparation of new material ultra-fine powder, can solve the problems of single silver powder oxidant, silver powder particle size and particle size distribution are difficult to control, etc., to achieve large-scale production, good dispersion, easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

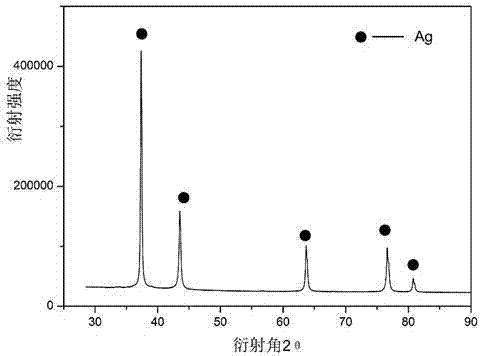

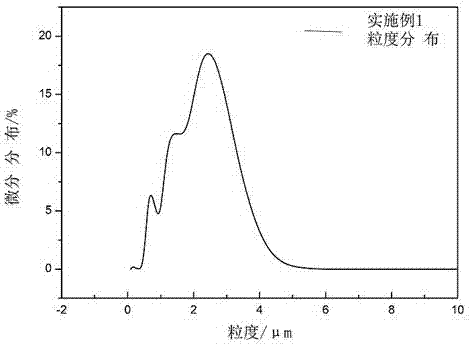

Embodiment 1

[0043] A method for preparing ultrafine silver powder, specifically comprising the steps of:

[0044] (1) Weigh 0.05mol silver nitrate and dissolve it in 1000mL water to prepare a silver nitrate solution with a concentration of 0.05mol / L, and place it in an ultrasonic generator in a constant temperature water bath at 20°C, with an ultrasonic frequency of 25KHz, combined with a mechanical stirring paddle at a stirring speed of 400r / L min, add 1.25g Tween 80 to the silver nitrate solution to make it disperse evenly, then add dropwise a sodium chloride solution with a concentration of 0.2mol / L at a speed of 1mL / min until no white precipitate is separated out, and obtain Silver chloride colloid;

[0045] (2) adjust the pH value of silver chloride colloid in step (1) with dilute hydrochloric acid to be 1;

[0046] (3) Dissolve 0.06mol of ascorbic acid and 0.25g of Tween 80 in 50mL of water, stir continuously to disperse them evenly, and obtain a reducing solution;

[0047] (4) Ad...

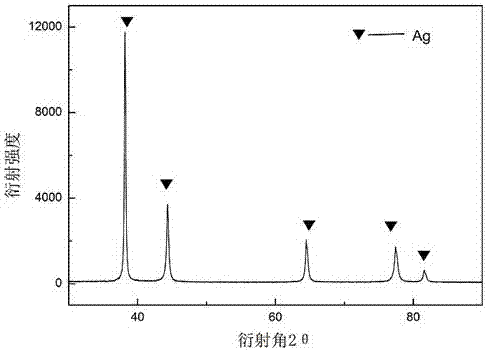

Embodiment 2

[0052] A method for preparing ultrafine silver powder, specifically comprising the steps of:

[0053] (1) Weigh 0.09mol silver nitrate and dissolve it in 260mL water to prepare a silver nitrate solution with a concentration of 0.35mol / L, and place it in a constant temperature water bath ultrasonic generator at 35°C with an ultrasonic frequency of 40KHz and a stirring speed of 800r with a mechanical stirring paddle / min, add 1.8g Tween 80 to the silver nitrate solution to make it evenly disperse, and then dropwise add a sodium chloride solution with a concentration of 0.5mol / L at a speed of 1mL / min until no white precipitate is separated out to obtain Silver chloride suspension;

[0054] (2) adjust the pH value of the silver chloride suspension in step (1) with dilute hydrochloric acid to be 1;

[0055] (3) Dissolve 0.18mol of ascorbic acid and 0.4g of Tween 80 in 100mL of water, and keep stirring to disperse evenly to obtain a reducing solution;

[0056] (4) Add the reducing...

Embodiment 3

[0061] A method for preparing ultrafine silver powder, specifically comprising the steps of:

[0062] (1) Weigh 0.3mol silver nitrate and dissolve it in 2000mL water to prepare a silver nitrate solution with a concentration of 0.15mol / L, and place it in a constant temperature water bath ultrasonic generator at 50°C with an ultrasonic frequency of 60KHz and a stirring speed of 600r with a mechanical stirring paddle / min, add 0.53g sodium dodecylbenzene sulfonate and 1g polyvinylpyrrolidone to make it dissolve, and then drop dilute hydrochloric acid with a concentration of 0.6mol / L at a speed of 1mL / min until there is no more White precipitate is separated out, and silver chloride colloid is obtained;

[0063] (2) Adjust the pH value of the silver chloride colloid in step (1) with dilute sodium hydroxide solution to make pH=2;

[0064] (3) Dissolve 0.3mol of ascorbic acid and 1.1g of Tween 80 in 100mL of water, stir continuously to disperse evenly, and obtain a reducing solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com