A kind of silica-based lightweight ceramic thermal protection material and its preparation method and application

A thermal protection material and lightweight ceramic technology, which is applied in the field of silica-based lightweight ceramic thermal protection ablation material and its preparation, can solve the problems of low material strength, low compressive strength, complicated preparation process, etc., and reduce the Thermal conductivity, high carbon residue rate, good heat insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

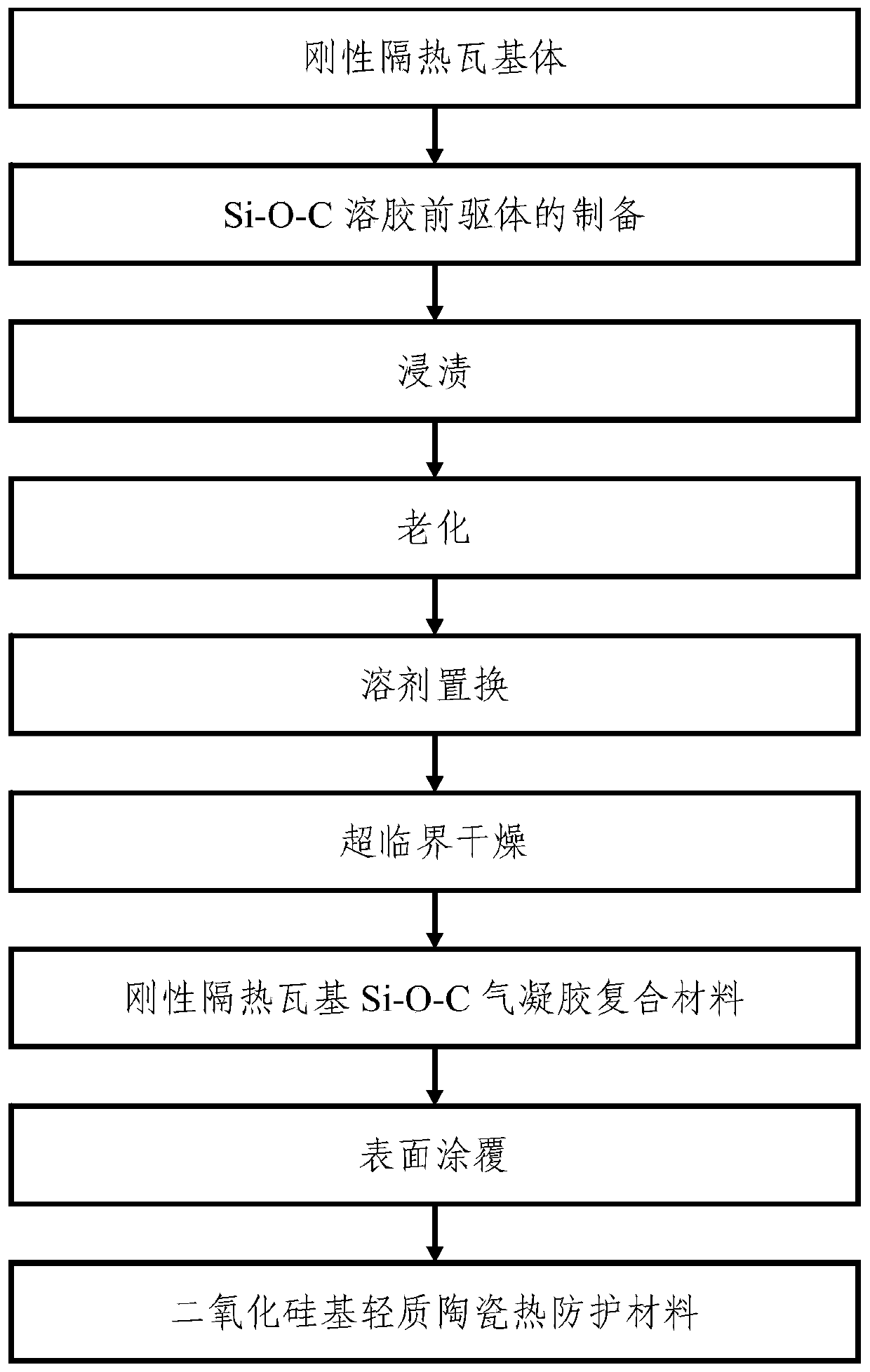

[0034] In a second aspect, the present invention provides a method for preparing a silica-based lightweight ceramic thermal protection material, the process flow chart of the preparation method for the thermal protection material is as follows figure 1 As shown, specifically, the following steps are included:

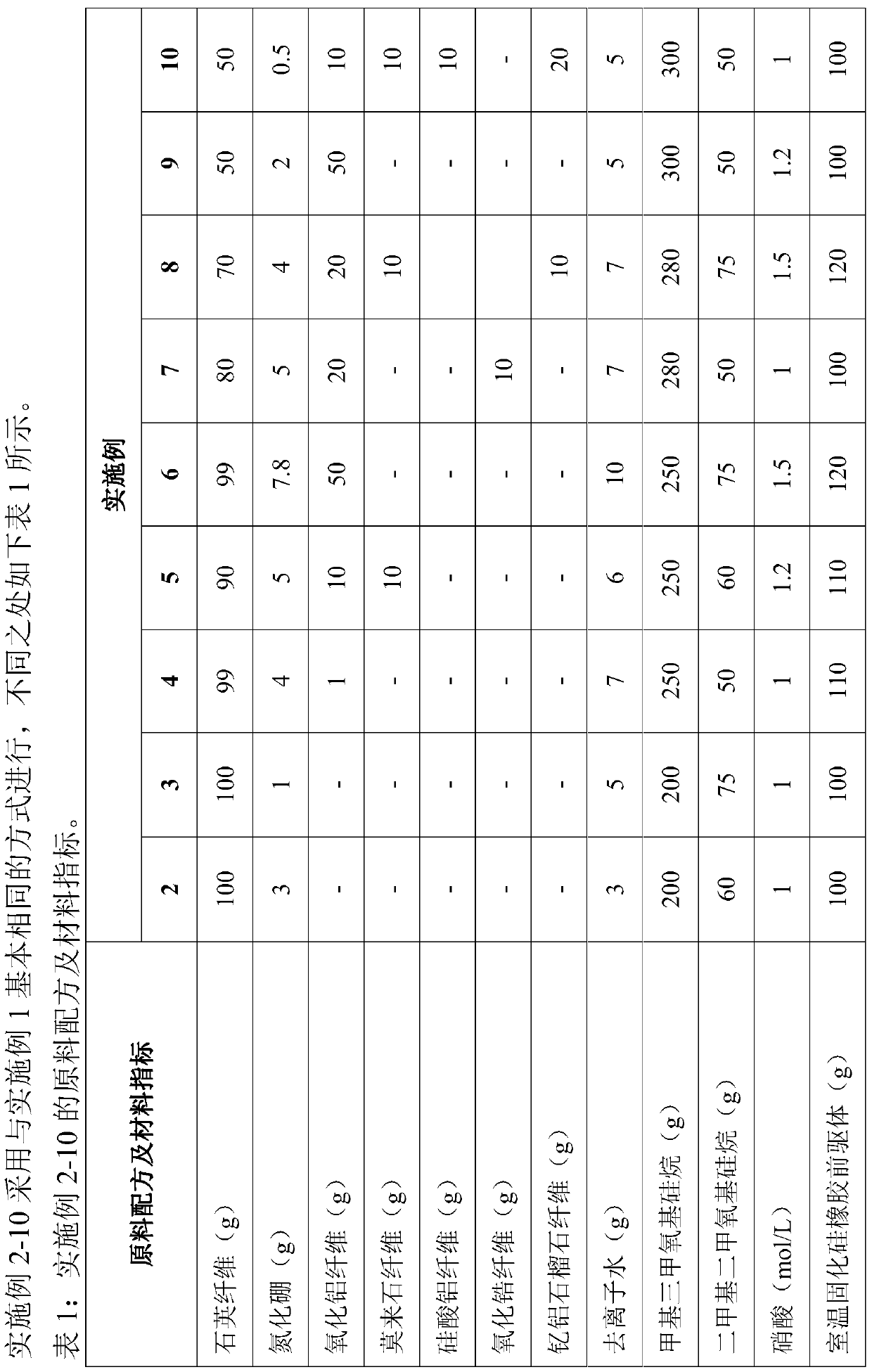

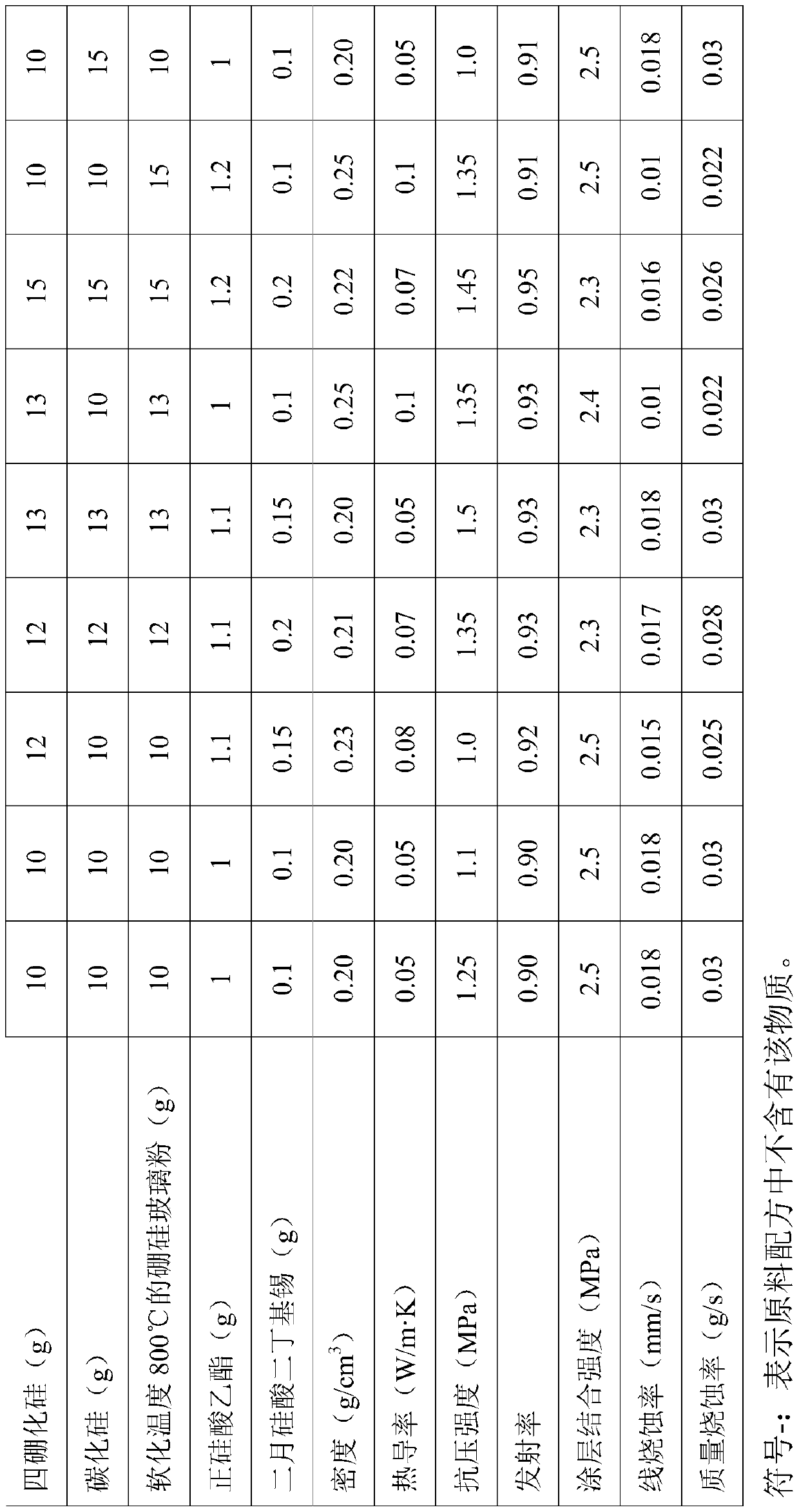

[0035] (1) Preparation of rigid heat-insulating tile matrix: Boron nitride with a mass fraction of 1 to 5% (for example, 1%, 2%, 3%, 4% or 5%), and a mass fraction of 50% to 99% ( Such as 50%, 55%, 60%, 65%, 70%, 75%, 80%, 85%, 90%, 95% or 99%) of quartz fiber and a mass fraction of 0% to 49% (such as 0% , 1%, 3%, 5%, 8%, 10%, 15%, 20%, 25%, 30%, 35%, 40%, 45%, 49%) fiber reinforcements are stirred with a large amount of water for 1~ After mixing for 2 hours (for example, 1, 1.5 or 2 hours), filter to obtain a solid mixture, and then pass the obtained solid mixture through drying and sintering steps in sequence to obtain a rigid heat-insulating tile matrix; the boron n...

Embodiment 1

[0042] Take 100g of quartz fiber, 5g of boron nitride powder and 10kg of deionized water, stir for 2 hours and then filter, press the filter cake to a pre-calculated height, then dry and sinter to obtain a rigid insulating tile made of quartz fiber. Then, pour 200g of methyltrimethoxysilane, 50g of dimethyldimethoxysilane, and 300mL of absolute ethanol into a 5000mL beaker, use magnetic stirring to mix well; then slowly add 200mL of 1mol / L Nitric acid catalyst, use an ice-water mixed bath outside the beaker to control the hydrolysis reaction rate, and continue stirring for 5 minutes after the nitric acid is added dropwise to obtain the required Si-O-C sol precursor. In a vacuum impregnation tank, vacuumize to a gauge pressure of 0.01MPa, then inject the Si-O-C sol precursor into the vacuum impregnation tank, and let the Si-O-C sol gel to obtain a rigid insulation tile Si-O-C wet Gel composite material, and then the rigid thermal insulation tile-based Si-O-C wet gel composite m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com