Method for planting agaricus blazei murill and co-producing organic fertilizer by using planting fungi residues of agaricus blazei murill

A technology of organic fertilizer and Agaricus blazei, which is applied in the field of Agaricus blazei planting and using its fungus residue to produce organic fertilizer at the same time, can solve the problems of low and unstable output of Agaricus blazei, poor water absorption and water retention, and insufficient utilization, so as to improve disease resistance and prevention. Disease ability, increased nitrogen fixation, favorable reproduction and increased effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

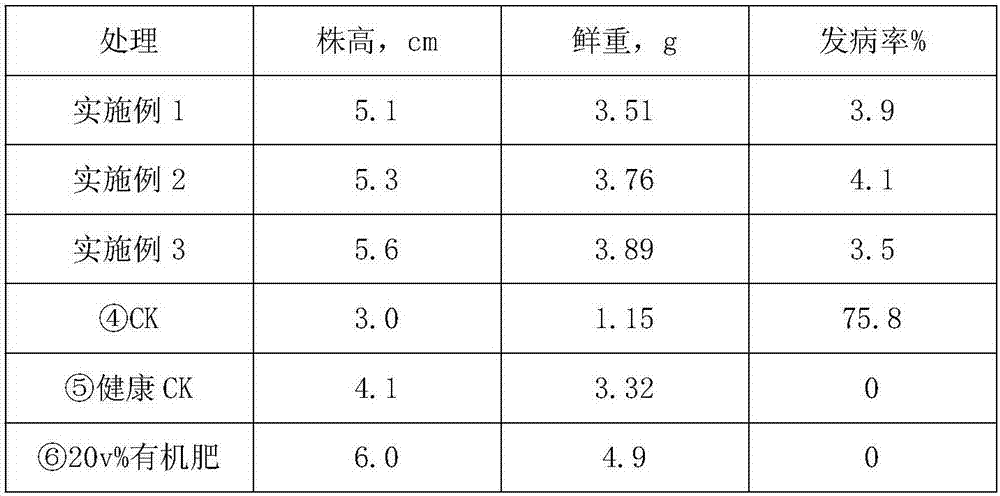

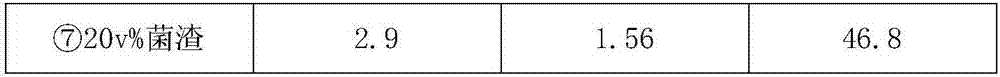

Examples

Embodiment 1

[0035] A kind of Agaricus blazei is planted and utilizes its method for planting fungus residue to produce organic fertilizer simultaneously, and it comprises the following steps:

[0036] (1) Centrally collect and pulverize the fresh non-decomposed crop stalks, crush the cotton stalks and corn stalks to a length of 5-10 cm, flatten the wheat straws, and then mix the crushed and flattened three kinds of straws in a ratio of 1:1:1;

[0037] (2) Pre-wetting the mixed stalks, and controlling the water content at 70%. After pre-wetting, add cow dung to build a pile, in which the mass ratio of cow dung to straw is 45:55. The bottom width of the pile is 2 meters and the height is 1.8-2 meters.

[0038] (3) The interval of fermentation is 6 days from the establishment of the heap to the first turning of the heap, and the temperature of the material is 55-65 degrees Celsius. Add calcium superphosphate when turning, the addition amount is 1 kg per 100 square meters, in order to speed ...

Embodiment 2

[0043] A kind of Agaricus blazei is planted and utilizes its method for planting fungus residue to produce organic fertilizer simultaneously, and it comprises the following steps:

[0044] (1) Centrally collect and pulverize fresh non-decomposed crop stalks, crush cotton stalks and corn stalks to a length of 5-10 cm, flatten corn cobs, and then mix the three kinds of crushed and flattened straws in a ratio of 1:1:1;

[0045] (2) Pre-wetting the mixed stalks, and controlling the water content at 90%. After pre-wetting, add cow dung to build a pile, in which the mass ratio of cow dung to straw is 45:55. The bottom width of the pile is 2 meters and the height is 1.8-2 meters.

[0046] (3) The interval of fermentation is 8 days from the establishment of the heap to the first turning of the heap, and the temperature of the material is 55-65 degrees Celsius. Add calcium superphosphate when turning, the addition amount is 1.5 kg per 100 square meters, in order to speed up auxiliary ...

Embodiment 3

[0051] A kind of Agaricus blazei is planted and utilizes its method for planting fungus residue to produce organic fertilizer simultaneously, and it comprises the following steps:

[0052] (1) Centrally collect and pulverize the fresh non-decomposed crop stalks, crush the cotton stalks and corn stalks to a length of 5-10 cm, flatten the wheat straws, and then mix the crushed and flattened three kinds of straws in a ratio of 1:1:1;

[0053] (2) pre-wetting the mixed stalks, and controlling the water content at 70-90%. After pre-wetting, add cow dung to build a pile, in which the mass ratio of cow dung to straw is 45:55. The bottom width of the pile is 2 meters and the height is 1.8-2 meters.

[0054] (3) The interval of fermentation is 7 days from the establishment of the heap to the first turning of the heap, and the temperature of the material is 55-65 degrees Celsius. Add calcium superphosphate when turning, the addition amount is 1.2 kg per 100 square meters, in order to s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com