Preparation method of low-temperature graphene-based nanoborate composite material

A graphene-based, composite material technology, applied in the petroleum industry, lubricating compositions, additives, etc., can solve the problems of different control conditions and complicated preparation process, and achieve low equipment investment, simple preparation process and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

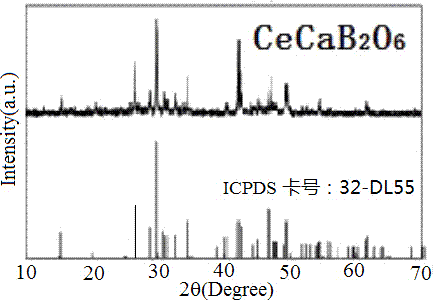

[0023] Firstly, 100 mg of graphene oxide, 2 g of organic solvent alkylphenol, 2 g of NN dimethylacetamide and 200 g of water were mixed and then ultrasonicated. The ultrasonic dispersion time was 2 hours, and a light yellow solution with a graphene oxide concentration of 0.5 mg / ml was obtained; Then, while stirring with the motor at a temperature of 80°C, add 5g of sodium borohydride and 5g of sodium citrate, and continue to stir for 1h; then add 0.5g of hexadecyl calcium borate and 0.5g of nano-cerium borate and continue to stir for 10h; continue to stir And heat up to 160 ℃ in the reflux reactor, carry out reflux reaction, keep stirring and keep warm for 6h, turn off the heat source, suction filter while it is hot, wash, dry to obtain the graphene-based nano borate composite material, such as figure 2 shown.

Embodiment 2

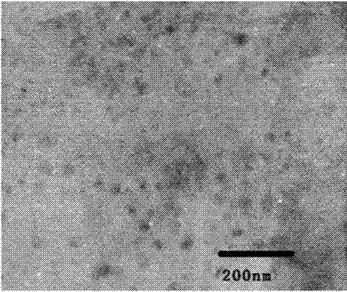

[0025] Firstly, 150 mg of graphene oxide, 3 g of organic solvent alkylphenol, 5 g of NN dimethylacetamide and 200 g of water were mixed and then ultrasonicated. The ultrasonic dispersion time was 2.5 h, and a light yellow solution with a graphene oxide concentration of 0.75 mg / ml was obtained. Afterwards, while stirring the motor at a temperature of 80°C, add 6g of sodium borohydride and 6g of sodium citrate, and continue to stir for 2h; then add 1g of hexadecyl calcium borate and 1g of nano-cerium borate and continue to stir for 15h; continue to stir and In the reflux reactor, the temperature is raised to 200°C, reflux reaction is carried out, continuous stirring and insulation for 8h, the heat source is turned off, suction filtration is hot, washed, and dried to obtain a graphene-based nano borate composite material, such as image 3 shown.

Embodiment 3

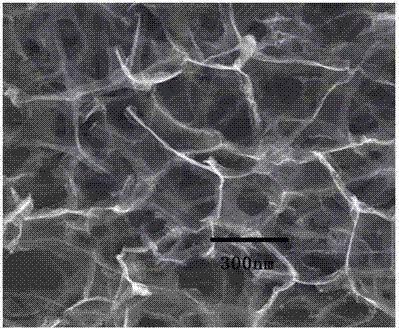

[0027] First, 200 mg of graphene oxide, 5 g of organic solvent alkylphenol, 6 g of NN dimethylacetamide and 200 g of water are mixed and then ultrasonicated, and the ultrasonic dispersion time is 3 h to obtain a light yellow solution with a graphene oxide concentration of 1 mg / ml; after that While stirring with the motor at a temperature of 80°C, add 8g of sodium borohydride and 8g of sodium citrate, and continue stirring for 2 hours; then add 3g of hexadecyl calcium borate and 3g of nano-cerium borate and continue stirring for 14 hours; continue stirring and reflux Heat up the temperature in the reactor to 150°C, carry out reflux reaction, keep stirring and keep warm for 20h, turn off the heat source, suction filter while it is hot, wash, and dry to obtain the graphene-based nano borate composite material, such as figure 1 shown.

[0028] In addition, when the process parameters of the above-mentioned method are changed within the scope of the content of the invention, those ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com