Zn-Mn series zinc alloy and preparing method and application thereof

A zinc alloy, zn-mn technology, used in prostheses, surgery, coatings, etc., can solve problems affecting normal bone growth, achieve good histocompatibility and hemocompatibility, excellent elongation, mechanical properties excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

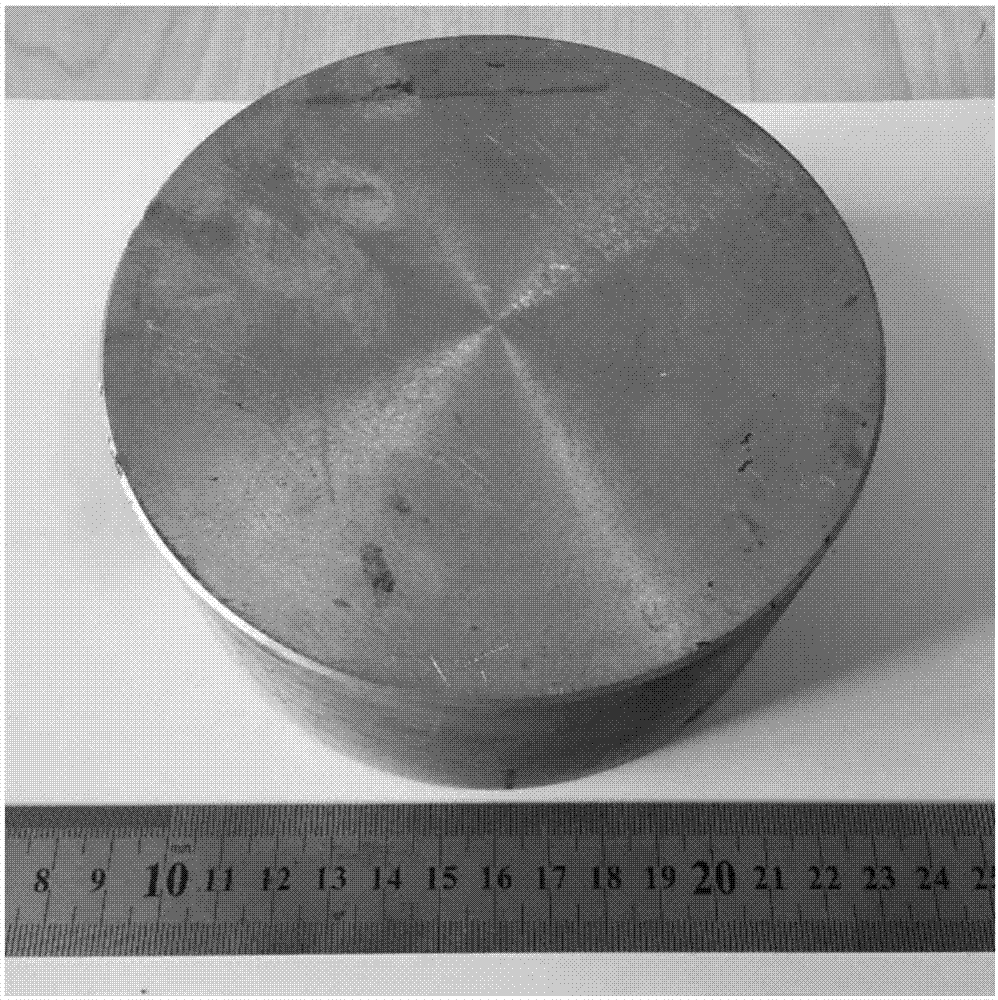

[0072] Embodiment 1, preparation as-cast Zn-Mn series alloy

[0073] Using pure Zn (99.99wt.%) and pure Mn (99.95wt.%) (purchased from Huludao Zinc Industry Co., Ltd.) as raw materials, according to different mass ratios (the mass ratios of Zn and Mn are 98:2, 98.5 respectively : 1.5, 99: 1, 99.2: 0.8, 99.6: 0.4, 99.9: 0.1) mixing, in CO 2 +SF 6 Under atmosphere protection, smelting at 800 ° C, after the raw materials are fully melted, after 10 minutes of heat preservation, the circulating water is rapidly cooled, and a Zn-Mn alloy ingot (that is, the Zn-Mn alloy of the present invention, such as figure 1 shown), wherein Zn-0.1Mn means that the mass ratio of Zn to Mn is 99.9:0.1, Zn-0.4Mn means that the mass ratio of Zn to Mn is 99.6:0.4, and Zn-0.8Mn means that the mass ratio of Zn to Mn is 99.2:0.8.

Embodiment 2

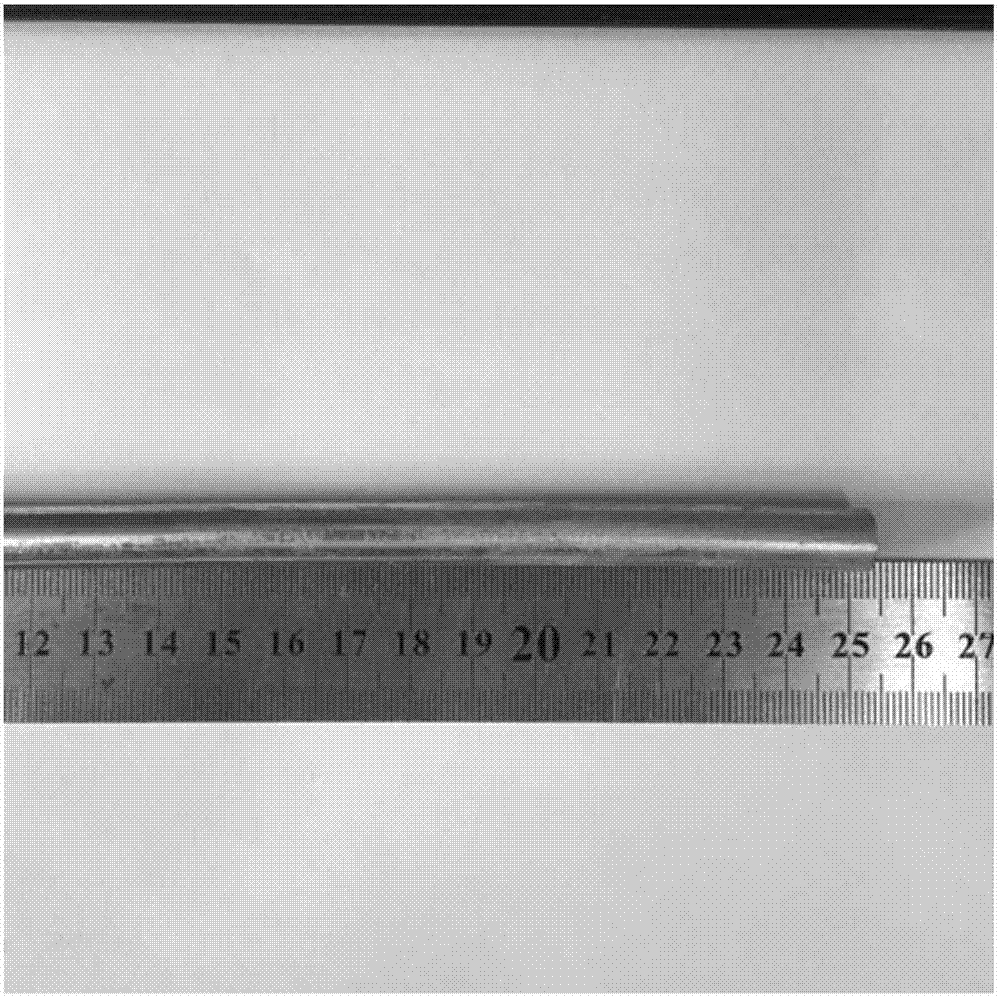

[0074] Embodiment 2, preparation extruded state Zn-Mn series alloy

[0075]First, the as-cast Zn-Mn alloy ingot is prepared according to the steps in Example 1 of the present invention, and the Zn-Mn alloy bar is prepared by extrusion (that is, the Zn-Mn zinc alloy of the present invention, such as figure 2 As shown), radial extrusion is adopted, the ingot is held for 2 hours, the holding temperature is 260°C, the extrusion temperature is 260°C, the extrusion ratio is 36, and the extrusion speed is 1mm / s to prepare a Zn-Mn alloy with a diameter of 10mm bar.

Embodiment 3

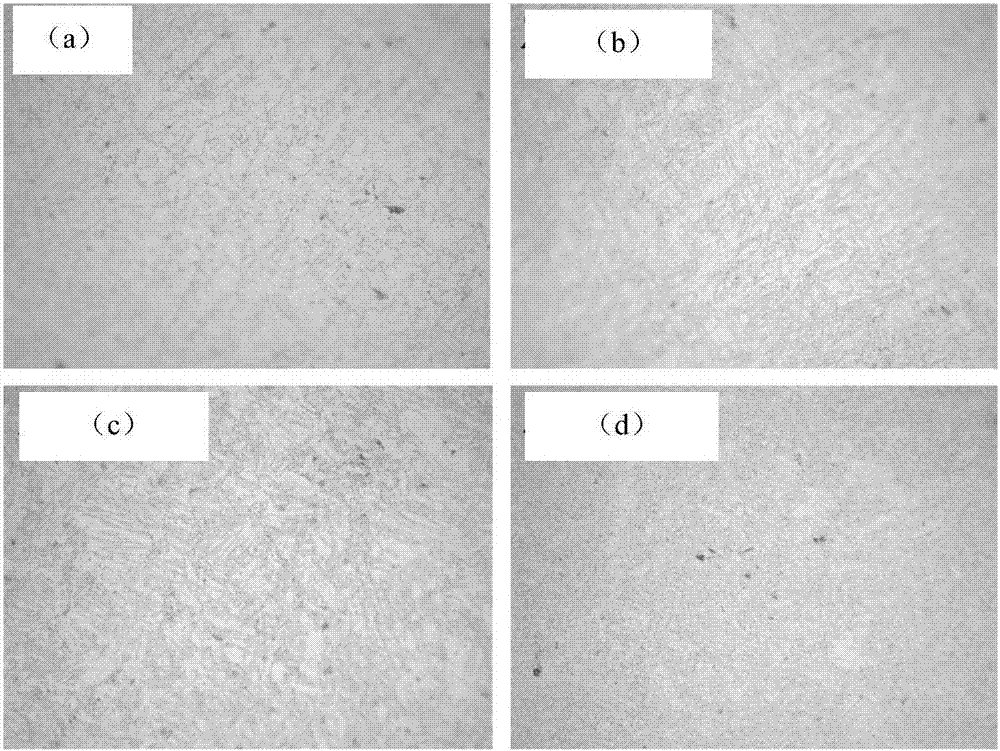

[0076] Embodiment 3, Zn-Mn series alloy microstructure analysis

[0077] The Zn-Mn alloy rod in Example 2 of the present invention was prepared by wire cutting to prepare a φ10x1mm sample, which was sequentially ground and polished by 400#, 800#, 1200# and 2000# SiC sandpaper series. After ultrasonic cleaning in acetone, absolute ethanol and deionized water for 15 min, dry at 25 °C. The sample was subjected to X-ray diffraction analysis, etched with 4% nitric acid alcohol for 5-30 seconds, washed with deionized water, dried, and observed under a metallographic microscope.

[0078] image 3 It is the metallographic picture of Zn-Mn alloy, from image 3 It can be seen that after extrusion, the crystal grains are fine, and the needle-like second phase is evenly distributed on the matrix. Figure 4 is the X-ray diffraction pattern, given by Figure 4 It can be seen that after adding Mn, the crystal structure of pure zinc changes, but the change is not obvious until adding 0.8w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com