Efficient and high-quality nickel-based high-temperature alloy surface salt bath chromizing agent and process thereof

A nickel-based superalloy, high-quality technology, applied in metal material coating process, coating, solid-state diffusion coating, etc., to achieve excellent surface hardness, less sticky salt, and no pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

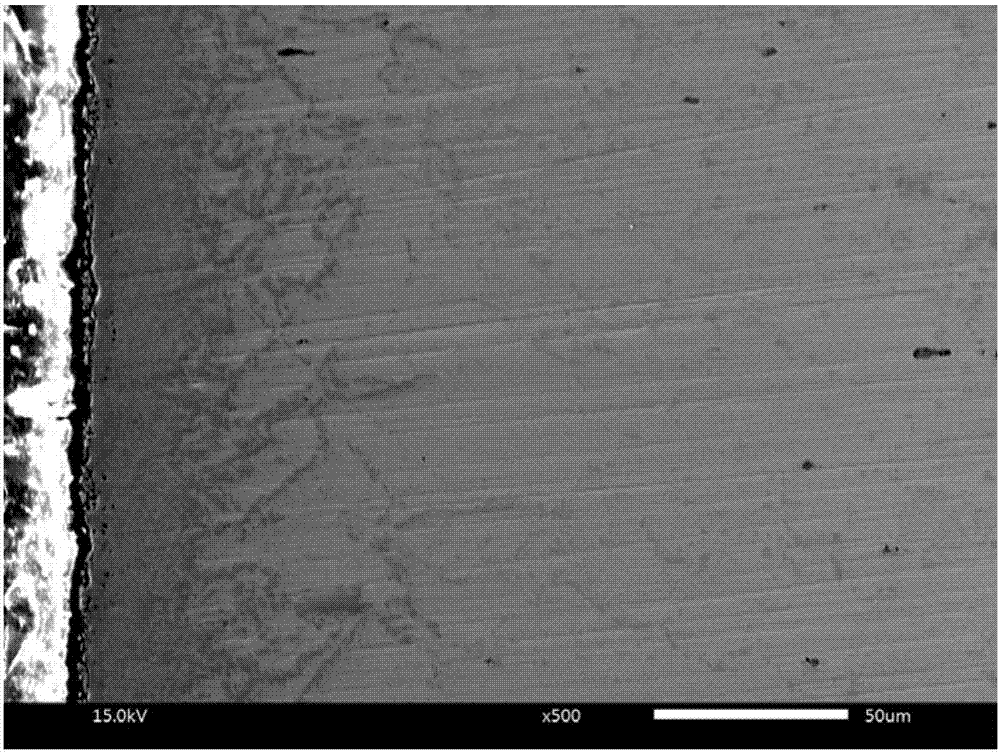

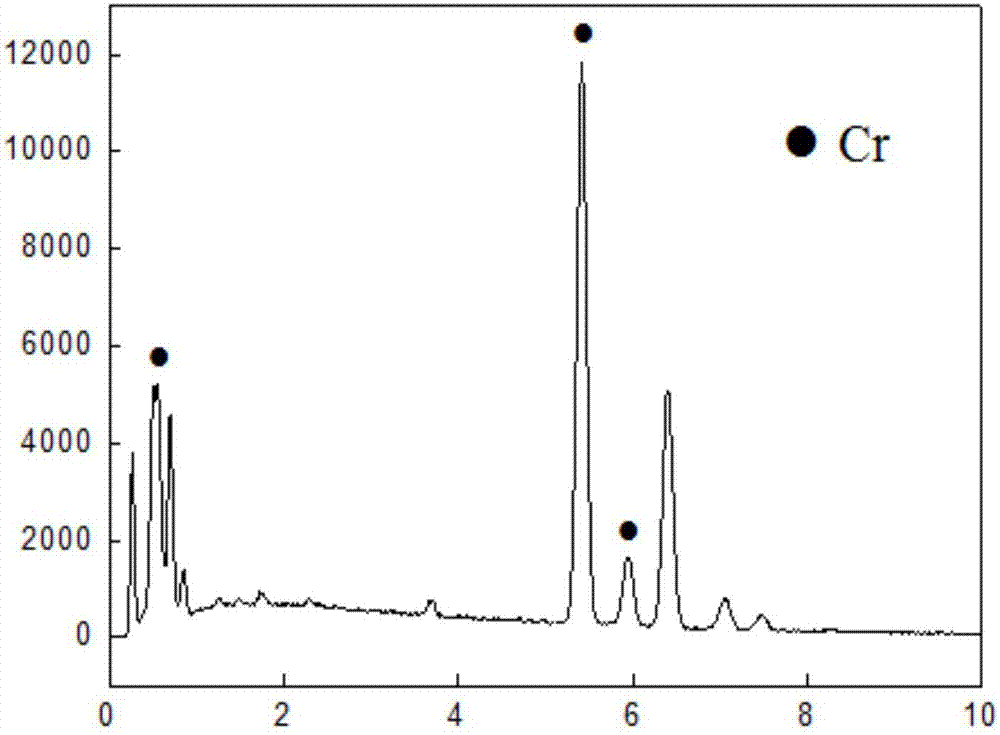

[0029] like Figure 1-2 shown.

[0030] The chromizing process is: surface pretreatment of nickel-based superalloy - chromizing treatment - cleaning the sample.

[0031] Wire-cut the nickel-based superalloy material into profiles of 10mm×10mm×3mm for later use.

[0032] (1) Surface pretreatment of nickel-based superalloy: After degreasing and cleaning with deionized water, the surface of nickel-based superalloy is sanded and mechanically polished, and the surface is polished to a roughness of Ra1 μm, then ultrasonically cleaned with acetone for 10 minutes, and rinsed with ethanol Blow dry the prepared sample.

[0033] (2) Chromizing treatment: Boron oxide (B 2 o 3 ) 60 grams, sodium fluoride (NaF) 16 grams, boron carbide (B 4 C) 8 grams, barium chloride (BaCl 2 )6 grams, chromium oxide (Cr 2 o 3 ) 10 grams into a crucible and placed in a box-type resistance furnace, heated to 1000°C, kept for 15 minutes to melt the infiltration agent evenly, and then cooled to the chro...

Embodiment 2

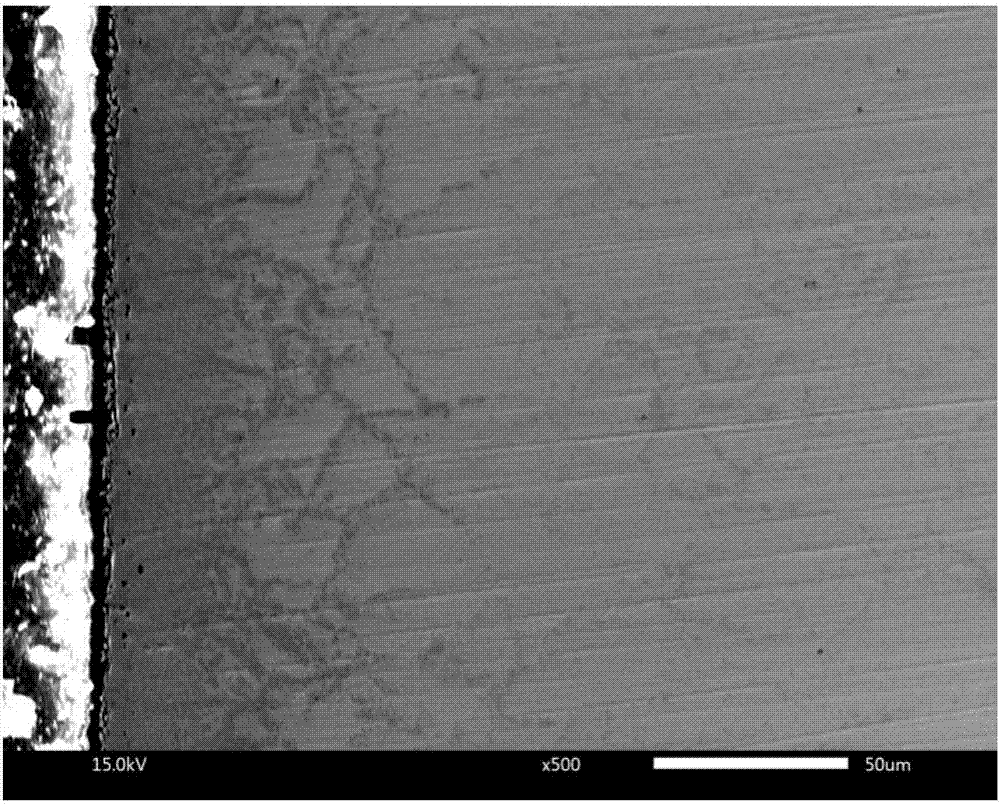

[0037] like Figure 3-4 shown.

[0038] The chromizing process is: surface pretreatment of nickel-based superalloy - chromizing treatment - cleaning the sample.

[0039] Wire-cut the nickel-based superalloy material into profiles of 10mm×10mm×3mm for later use.

[0040] (1) Surface pretreatment of nickel-based superalloy: After degreasing and cleaning with deionized water, the surface of nickel-based superalloy is sanded and mechanically polished, and the surface is polished to a roughness of Ra1 μm, then ultrasonically cleaned with acetone for 10 minutes, and rinsed with ethanol Blow dry; prepare the sample.

[0041] (2) Chromizing treatment: Boron oxide (B 2 o 3 ) 61 grams, sodium fluoride (NaF) 13 grams, boron carbide (B 4 C) 6 grams, barium chloride (BaCl 2 )8 grams, chromium oxide (Cr 2 o 3 ) 12 grams into a crucible and placed in a box-type resistance furnace, heated to 1000°C, kept for 15 minutes to melt the infiltration agent evenly, and then cooled to the chro...

Embodiment 3

[0045] The chromizing process is: surface pretreatment of nickel-based superalloy - chromizing treatment - cleaning the sample.

[0046] Wire-cut the nickel-based superalloy material into profiles of 10mm×10mm×3mm for later use.

[0047] (1) Surface pretreatment of nickel-based superalloy: After degreasing and cleaning with deionized water, the surface of nickel-based superalloy is sanded and mechanically polished, and the surface is polished to a roughness of Ra1 μm, then ultrasonically cleaned with acetone for 10 minutes, and rinsed with ethanol Blow dry the prepared sample.

[0048] (2) Chromizing treatment: Boron oxide (B 2 o 3 ) 63 grams, sodium fluoride (NaF) 12 grams, boron carbide (B 4 C) 6 grams, barium chloride (BaCl 2 ) 9 grams, chromium oxide (Cr 2 o 3 ) 10 grams into a crucible and placed in a box-type resistance furnace, heated to 1000°C, kept for 15 minutes to melt the infiltrating agent evenly, and then cooled to the chromizing temperature (900-950°C) to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com