Machining technology of cotton fiber and metal wire blended yarn

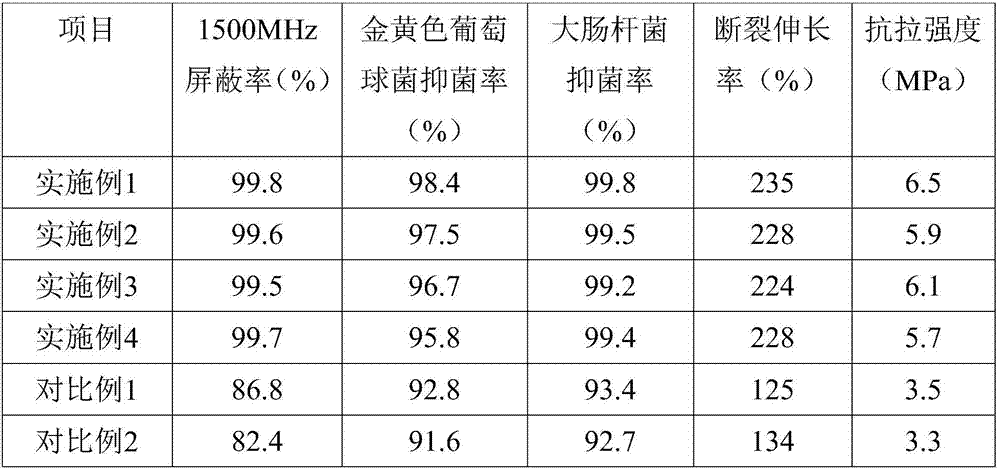

A blended yarn and processing technology, which is applied in fiber treatment, plant fiber, biochemical fiber treatment, etc., can solve the problems of poor anti-pilling performance, uneven yarn dryness, high production cost, etc., and achieve excellent antibacterial performance , beautiful metallic luster, excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A processing technology of cotton fiber and metal wire blended yarn, comprising the following steps:

[0024] (1) Metal wire preparation: Pre-crushing stainless steel powder to 100-200 mesh, adding it to a planetary ball mill tank, adding ethanol with 6 times the mass of stainless steel powder, and adding 20-30 mm in size according to the ball-to-material ratio of 42:1. Grinding balls, heating up to 40°C, milling at a speed of 480r / min for 15 hours; after cooling to room temperature, mix copper powder, zinc powder, cobalt powder, nickel powder, and graphite powder in a mass ratio of 3:1:1:1 : 0.2 was added into the ball mill jar, and ground at room temperature and at a speed of 250r / min for 20 hours to obtain a mixture; the mixture was washed with ethanol for 3 times, concentrated under reduced pressure to remove ethanol to obtain a dry material; the dry material was hot-pressed and sintered at 1365°C to obtain an alloy ; The alloy is obtained by a single wire drawing m...

Embodiment 2

[0029] A processing technology of cotton fiber and metal wire blended yarn, comprising the following steps:

[0030] (1) Metal wire preparation: Pre-crushing stainless steel powder to 100-200 mesh, adding it to a planetary ball mill tank, adding ethanol with 8 times the mass of stainless steel powder, and adding 20-30 mm in size according to the ball-to-material ratio of 46:1. Grinding balls, heating up to 42°C, ball milling at a speed of 500r / min for 14 hours; after cooling to room temperature, mix copper powder, zinc powder, cobalt powder, nickel powder, and graphite powder in a mass ratio of 3:1:1:1 : 0.2 was added to the ball mill tank, and ground at room temperature and at a speed of 300r / min for 21 hours to obtain a mixture; the mixture was rinsed with ethanol for 5 times, concentrated under reduced pressure to remove ethanol to obtain a dry material; the dry material was hot-pressed and sintered at 1400°C to obtain an alloy ; The alloy is obtained by a single wire drawi...

Embodiment 3

[0035] A processing technology of cotton fiber and metal wire blended yarn, comprising the following steps:

[0036] (1) Metal wire preparation: Pre-crushing stainless steel powder to 100-200 mesh, adding it to a planetary ball mill tank, adding ethanol with 6 times the mass of stainless steel powder, and adding 20-30 mm in size according to the ball-to-material ratio of 50:1. Grinding balls, heating up to 45°C, ball milling at a speed of 600r / min for 15 hours; after cooling to room temperature, mix copper powder, zinc powder, cobalt powder, nickel powder, and graphite powder in a mass ratio of 3:1:1:1 :0.2 was added to the ball mill jar, and ground at room temperature and at a speed of 300r / min for 20 hours to obtain a mixture; the mixture was rinsed with ethanol for 4 times, concentrated under reduced pressure to remove ethanol to obtain a dry material; the dry material was hot-pressed and sintered at 1450°C to obtain an alloy ; The alloy is obtained by a single wire drawing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com