All-solid flexible micro super capacitor based on GQD/Co(OH)2 composite material

A technology of supercapacitors and composite materials, which is applied in the manufacture of hybrid capacitor electrodes, hybrid capacitor current collectors, and hybrid/electric double layer capacitors. It can solve the problems of low matrix selectivity, short cycle life, and small specific capacitance, and achieve The effect of high energy density, high specific capacity, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

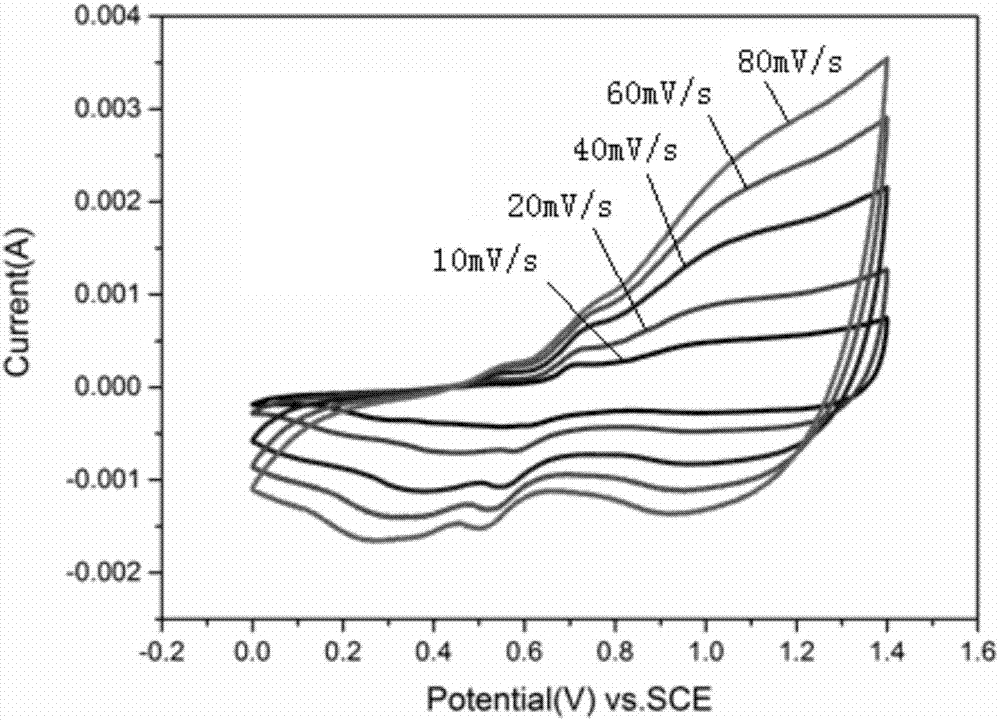

[0028] A GQD / Co(OH) based 2 The all-solid flexible micro-supercapacitor of composite material, its preparation comprises the following steps:

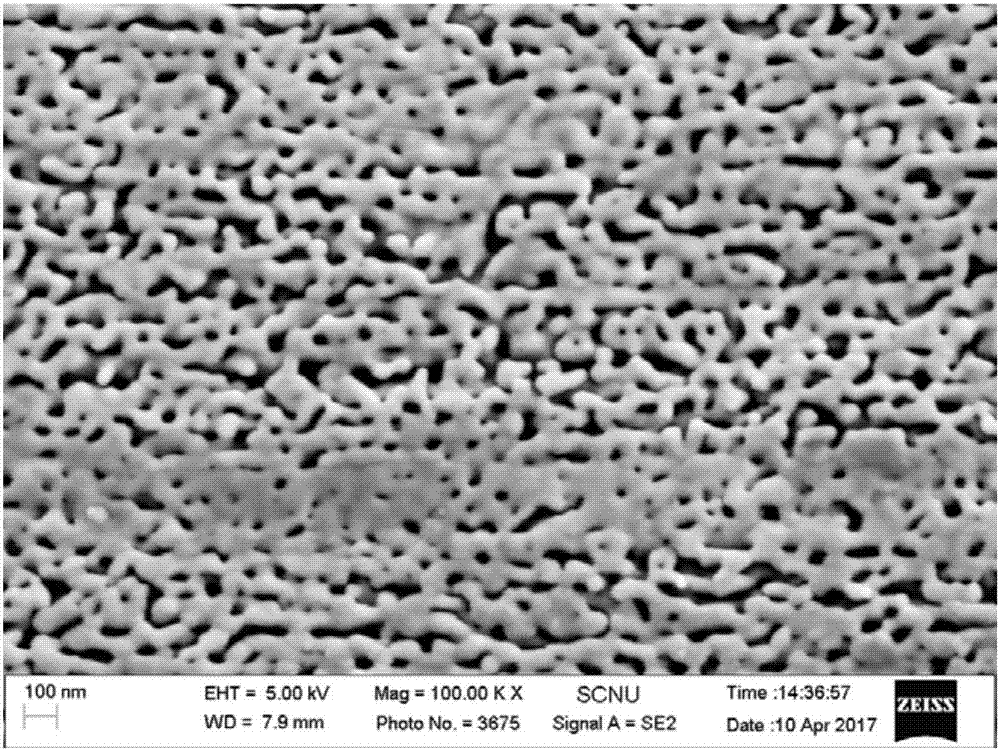

[0029] (1) Preparation of a nanoporous gold wire current collector: a gold-silver alloy wire with a diameter of 300 μm was immersed in nitric acid for 48 hours, and cleaned after corrosion.

[0030] (2)GQD / Co(OH) 2 Preparation of composite materials

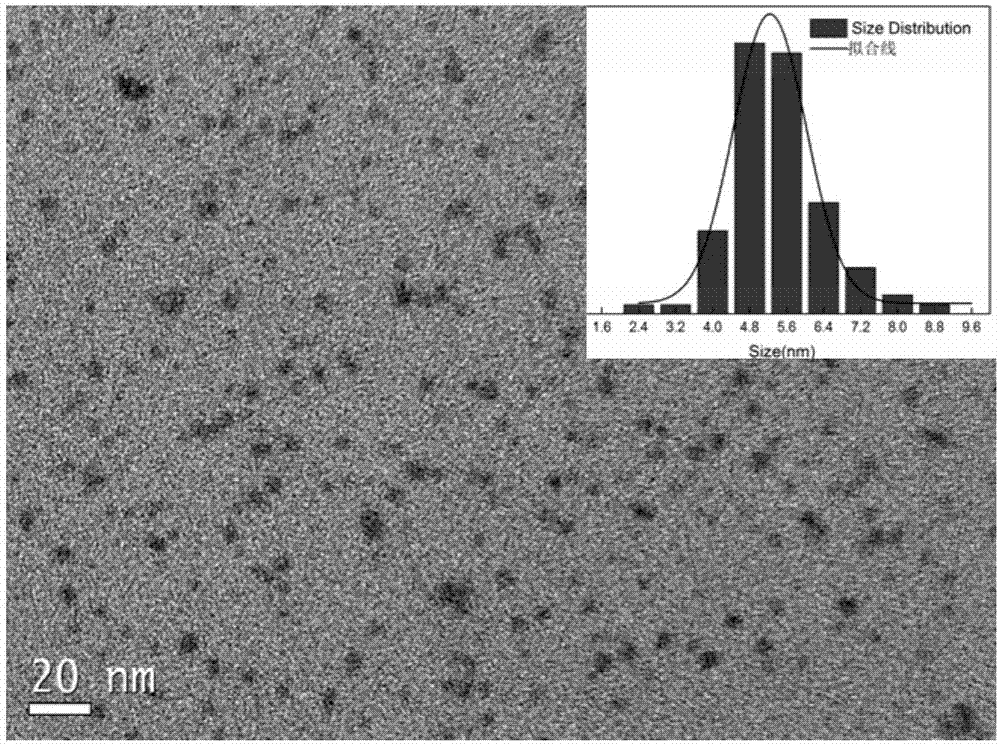

[0031] a) Synthesis of GQD: Pour 540mg of graphite oxide into 40mL of organic solvent (DMF), mix evenly with ultrasound, transfer to a reaction kettle for solvothermal reaction, the temperature is 200°C, and the reaction time is 8h; after the reaction is completed, cool to room temperature, After pouring out, use a 200 μm microporous membrane to filter to obtain the GQD solution;

[0032] b)GQD / Co(OH) 2 The preparation of composite material: dry a) make GQD solution, the GQD powder of gained is diluted to three times volume (120mL) of original organic solution with deionized water (th...

Embodiment 2

[0039] The present invention is based on GQD / Co(OH) 2 An all-solid flexible micro-supercapacitor of composite materials, which comprises the following steps:

[0040] (1) Preparation of a nanoporous gold wire current collector: a gold-silver alloy wire with a diameter of 20 μm was immersed in nitric acid for 12 hours, and cleaned after corrosion.

[0041] (2)GQD / Co(OH) 2 Preparation of composite materials

[0042] a) Synthesis of GQD: 540mg of graphite oxide was poured into 40mL of organic solvent (DMF), mixed evenly by ultrasonic, transferred to the reaction kettle for solvothermal reaction, the reaction temperature was 160°C, the reaction time was 10h, after the reaction was completed, cooled to room temperature, poured After extraction, the GQD solution was obtained by suction filtration with a 450 μm microporous membrane.

[0043] b)GQD / Co(OH) 2 Preparation of composite materials: Dilute the GQD powder obtained after drying the GQD solution to three times (120mL) of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com