Three-dimensional hollow material, preparation method thereof, and application thereof in electrochemical energy storage devices

A hollow, three-dimensional technology, applied in the field of preparation of self-supporting three-dimensional hollow carbon-based electrodes, can solve the problems of complicated process, small output, pollution, etc., and achieve the effect of mild reaction, good liquid absorption and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] As mentioned above, the present invention provides a three-dimensional hollow material and its preparation method, as well as the application of the above material in electrochemical energy storage devices. The preparation method is as follows:

[0053] 1. The preparation of three-dimensional hollow carbon material of the present invention comprises:

[0054] 1) First cut the resin foam containing ether bonds (such as phenol-formaldehyde resin foam, aminophenol-formaldehyde resin foam, aniline-formaldehyde resin foam, melamine-formaldehyde resin foam, urea-formaldehyde resin foam) into size-rated block materials, Place in a corundum or graphite crucible capable of withstanding high temperatures. Carbonization process can add catalysts (boron and its compounds, iron and its compounds, nickel and its compounds, silicon and its compounds, germanium and its compounds, copper and its compounds, calcium and its compounds, magnesium and its compounds, aluminum and its compoun...

Embodiment 1

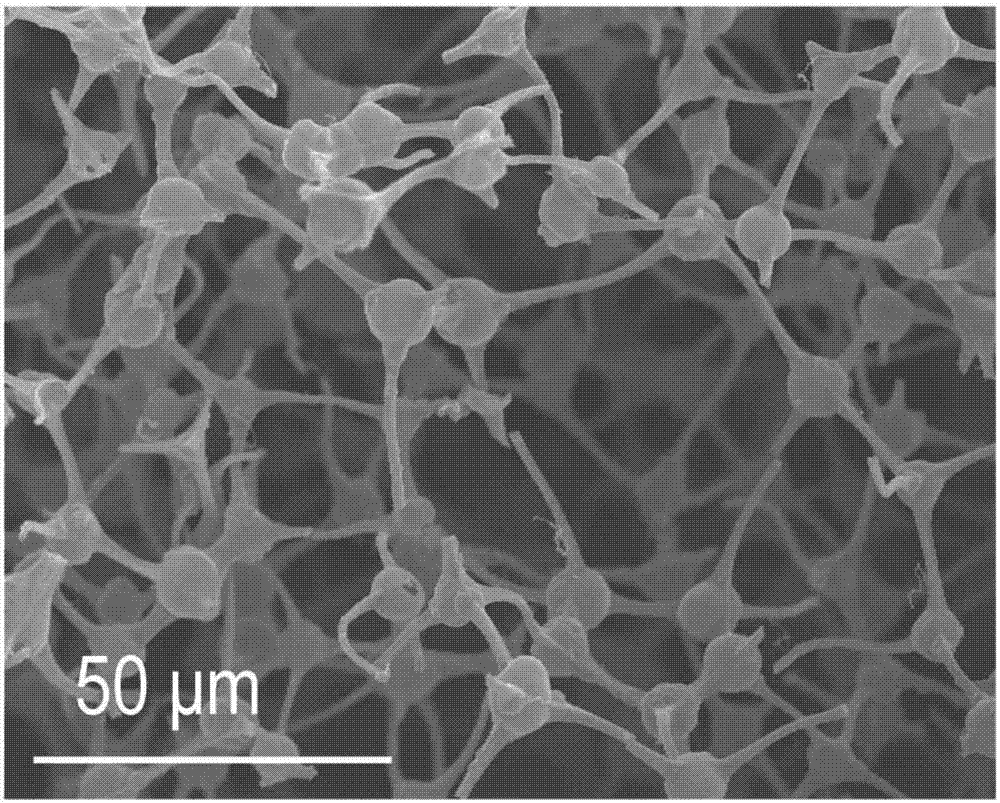

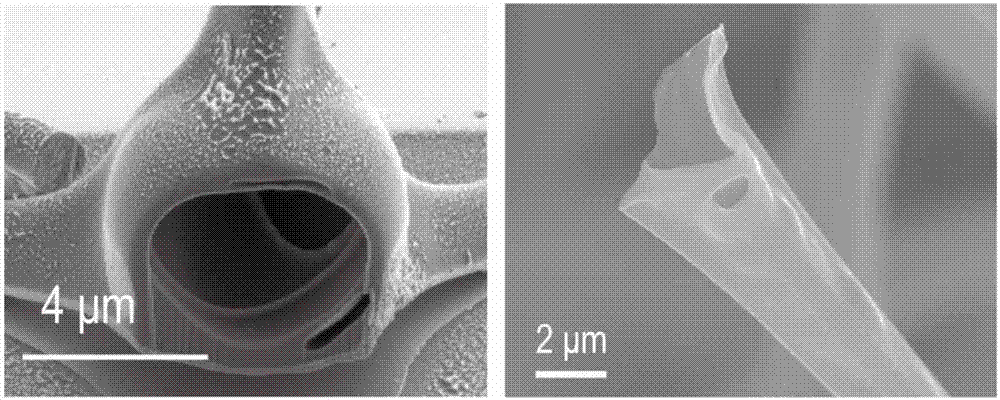

[0063] 1. Preparation of self-supporting three-dimensional hollow carbon using melamine-formaldehyde resin as precursor

[0064] Cut the melamine-formaldehyde resin foam containing ether bonds (ether bonds account for 50% of all bridge bonds) into blocks, with a length × width × height of 40 × 40 × 15mm, put them in a corundum crucible, and transfer them to a tube in the furnace.

[0065] Under normal pressure and oxygen-free nitrogen atmosphere protection conditions, the temperature was raised to 1000°C at a rate of 15°C / min, calcined at this temperature for 6h, and then cooled to room temperature to obtain a length×width×height of 15×15×6mm block-like three-dimensional hollow carbon.

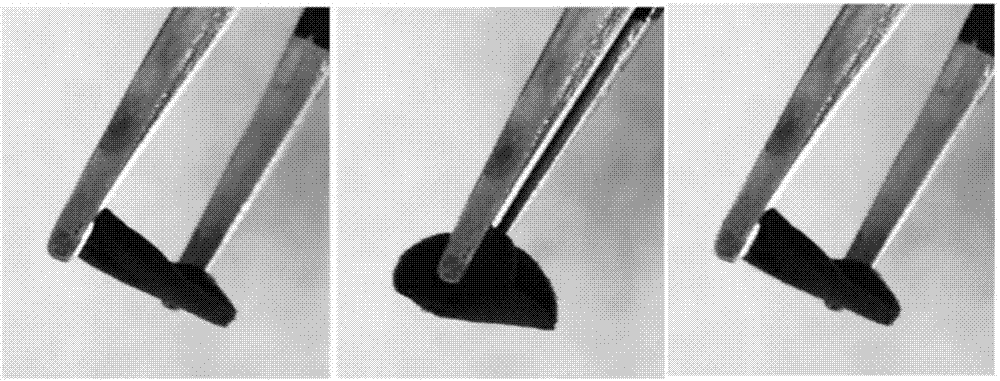

[0066] 2. Preparation of flexible self-supporting three-dimensional hollow carbon electrodes

[0067] Cut the block-like three-dimensional hollow carbon into thin slices with a thickness of 500 μm with a knife, and then cut the thin slices into circular electrode pieces with a diameter of 10...

Embodiment 2

[0078] 1. Preparation of self-supporting three-dimensional hollow carbon using urea-formaldehyde resin as precursor

[0079] Cut the urea-formaldehyde resin foam containing ether bonds (ether bonds account for 30% of all bridge bonds) into blocks, and the length × width × height is 50 × 50 × 20mm, and then soaked in 0.1M FeCl 3 ·6H 2 O (catalyst) solution, soaking time is 30min, take out and dry at 80°C, put in corundum crucible and transfer to tube furnace.

[0080] Under normal pressure and oxygen-free nitrogen atmosphere protection conditions, the temperature was raised to 1300°C at a rate of 10°C / min, calcined at this temperature for 0.5h, and then cooled to room temperature, and then the remaining catalyst was washed off with 1M nitric acid solution , and then washed several times with distilled water to neutrality to obtain a block-shaped three-dimensional hollow carbon with a length×width×height of 17×16×6 mm.

[0081] 2. Preparation of flexible self-supporting three-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Coulombic efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com