Preparation method of hexaphenoxycyclotriphosphazene

A technology of hexaphenoxycyclotriphosphazene and hexachlorocyclotriphosphazene, which is applied in the field of preparation of hexaphenoxycyclotriphosphazene, can solve problems such as post-processing troubles and increase production costs, and achieve simplified separation and purification way, reduce the formation of by-products, and improve the effect of product yield and purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

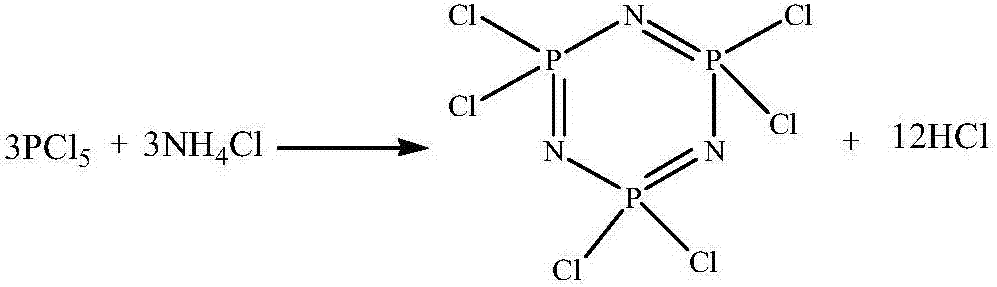

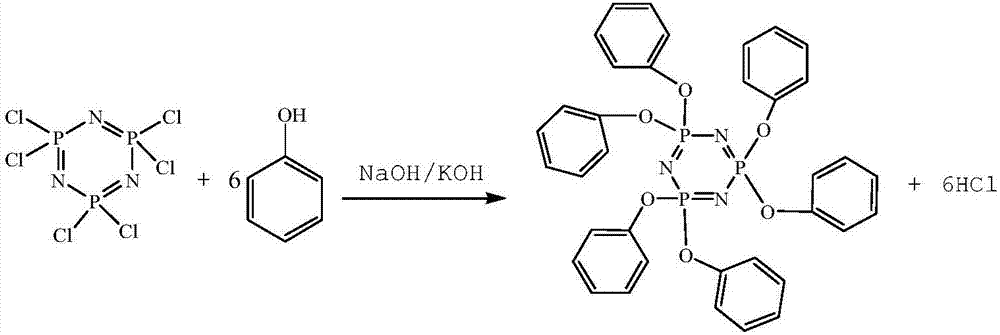

Method used

Image

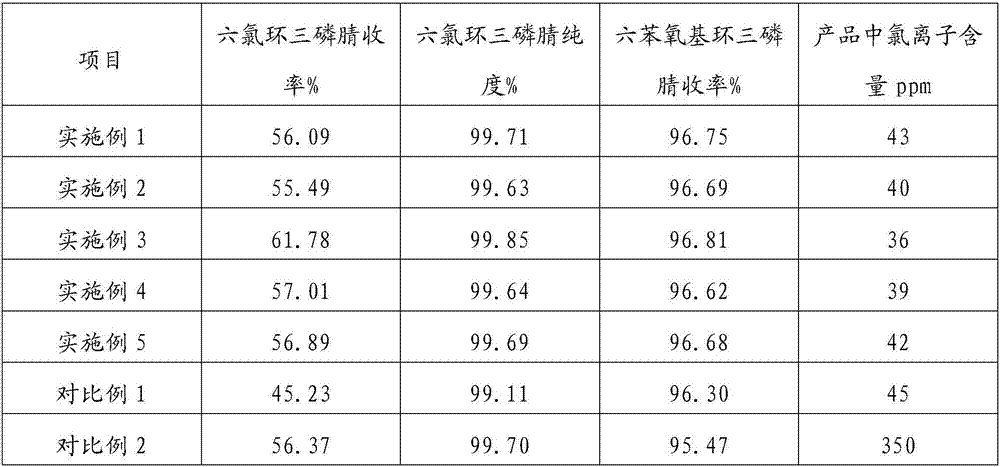

Examples

Embodiment 1

[0034] Add ammonium chloride, inert solvent chlorobenzene, and a mixed catalyst of magnesium chloride and pyridine with a mass ratio of 1:3 to the synthesis kettle, mix evenly and heat up to 135°C, and use a frequency conversion solid feeder to dissolve phosphorus pentachloride within 10 hours. The solid is evenly dropped into the synthesis kettle, the consumption of chlorobenzene is 1.5 times that of phosphorus pentachloride, and the mass ratio of phosphorus pentachloride, ammonium chloride, and mixed catalyst is 1:0.28:0.06; keep the temperature at 135 ° C until the end of the reaction. After the complete reaction of phosphorus chloride is completed, the temperature is lowered to 40°C, excess ammonium chloride and catalyst are filtered out, the solvent is removed from the feed solution under reduced pressure, the temperature is lowered to 10°C, and hexachlorocyclotriphosphazene is obtained by centrifugation.

[0035] Add the inert solvent chlorobenzene, phenol, sodium hydroxi...

Embodiment 2

[0038] Add ammonium chloride, inert solvent toluene, and a mixed catalyst of zinc chloride and pyridine with a mass ratio of 1:2.5 to the synthesis kettle, mix well and then heat up to 115°C, and use a frequency conversion solid feeder to dissolve pentachloride within 15 hours. Phosphorus solids are evenly put into the synthesis kettle, the amount of inert solvent toluene is twice that of phosphorus pentachloride, and the mass ratio of phosphorus pentachloride, ammonium chloride, and mixed catalyst is 1:0.25:0.04; keep the temperature at 115°C until the end of the reaction After the complete reaction of phosphorus pentachloride is completed, cool down to 40°C, filter out excess ammonium chloride and catalyst, remove the solvent toluene from the feed solution under reduced pressure, cool down to 10°C, and centrifuge to obtain hexachlorocyclotriphosphazene.

[0039] Add inert solvent toluene, phenol, potassium hydroxide and water into the synthesis kettle, stir and dissolve, then...

Embodiment 3

[0042]Add ammonium chloride, inert solvent tetrachloroethane, and a mixed catalyst of magnesium chloride and pyridine with a mass ratio of 1:3 in the synthesis kettle, mix well and then heat up to 145°C, and use a frequency conversion solid feeder to dissolve the pentachloride within 12 hours. Phosphate solids are evenly put into the synthesis kettle, the amount of inert solvent tetrachloroethane is 3 times that of phosphorus pentachloride, and the mass ratio of phosphorus pentachloride, ammonium chloride, and mixed catalyst is 1:0.3:0.08; keep the temperature at 145 °C to the end of the reaction, after the complete reaction of phosphorus pentachloride is completed, cool down to 40 °C, filter out excess ammonium chloride and catalyst, remove the solvent tetrachloroethane from the feed solution under reduced pressure, cool down to 10 °C, and centrifuge to obtain six Chlorocyclotriphosphazene.

[0043] Add the inert solvent tetrachloroethane, phenol, sodium hydroxide and water i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com