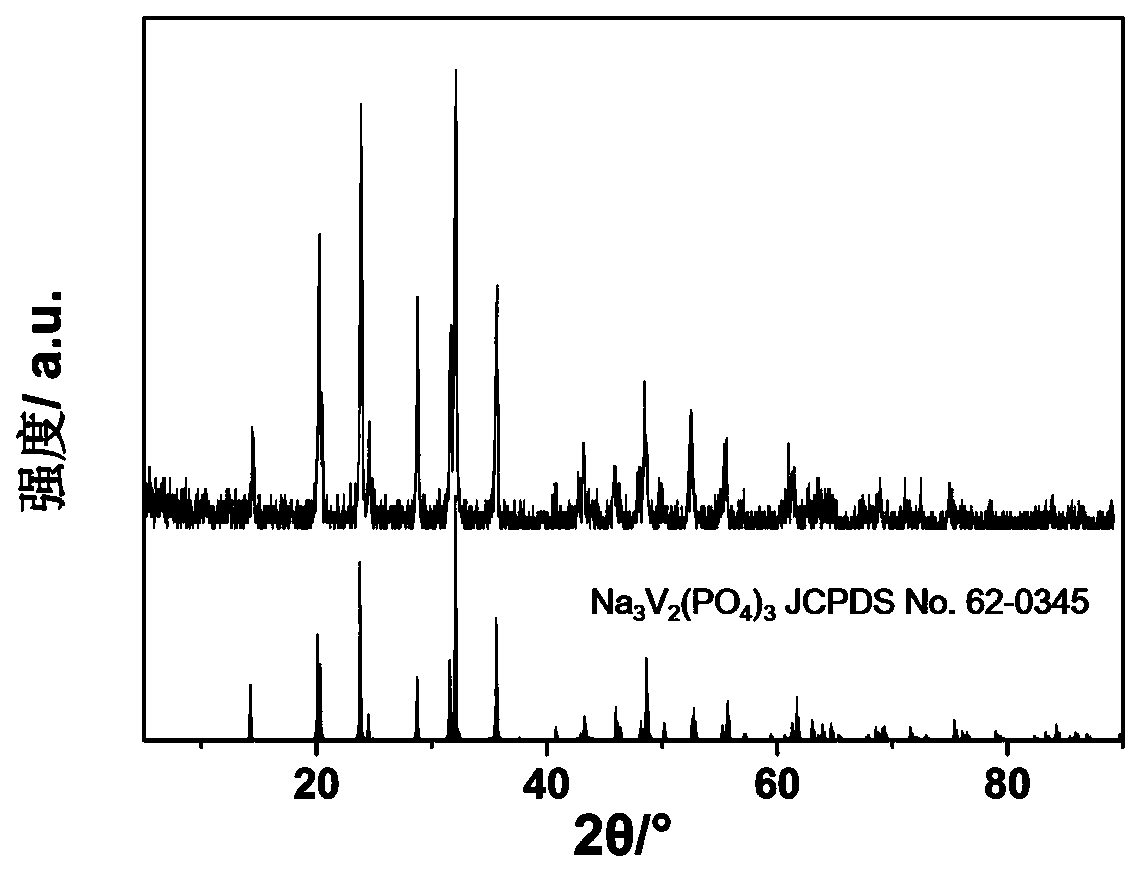

A kind of composite sodium ion battery cathode material na 3 v 2 (po 4 ) 3 /c and its preparation method

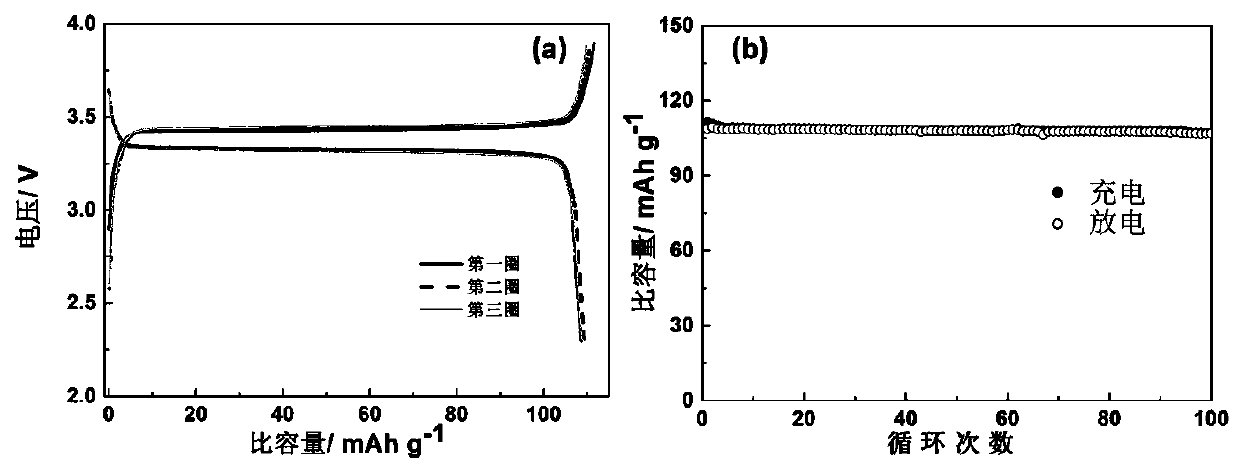

A sodium-ion battery and composite material technology, which is applied in the field of preparation of sodium-ion battery cathode materials and Na3V23/C composite materials, can solve problems such as difficult to achieve theoretical capacity, poor conductivity, and poor rate performance, and achieve good cycle performance, Low-cost, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

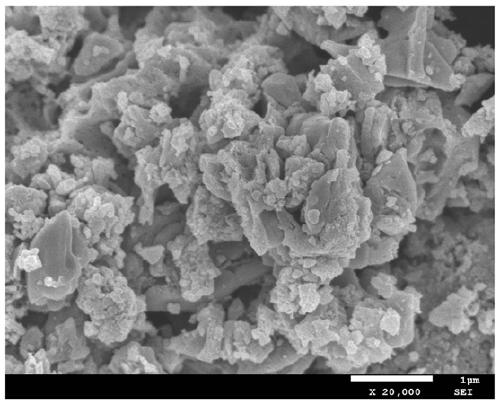

Embodiment 1

[0020] Weigh 3mmol of sodium carbonate, 2mmol of vanadium pentoxide, and 5mmol of hexamethylenetetramine and dissolve in a small beaker containing 20mL of deionized water, stir for 30min until it is fully dissolved; transfer the resulting mixed solution to a hydrothermal liner Add deionized water to 80% of the volume of the inner tank, then hydrothermally heat it in a blast oven at 120°C for 24 hours, and cool it naturally to obtain a mesophase liquid. Weigh 0.05g of citric acid and 6mmol of ammonium dihydrogen phosphate in a beaker containing 20mL of deionized water, stir for 20 minutes until it is fully dissolved, then slowly add the cooled mesophase liquid to the beaker, and stir after the addition is complete 30min to orange-yellow color. Then put the beaker in a 65°C blast oven for 36 hours until it is completely dry. The precursor powder obtained after drying was placed in a nitrogen atmosphere at 350°C for 4 hours and 750°C for 8 hours. Get Na after cooling 3 V 2 (PO 4...

Embodiment 2

[0022] Weigh 3mmol of sodium acetate, 2mmol of vanadium pentoxide, and 5mmol of hexamethylenetetramine in a small beaker containing 20mL of deionized water, stir for 30min until it is fully dissolved; transfer the resulting mixed solution to a hydrothermal liner Add deionized water to 80% of the volume of the inner tank, then hydrothermally heat it in a blast oven at 120°C for 24 hours, and cool it naturally to obtain a mesophase liquid. Weigh 0.05g glucose and 6mmol ammonium dihydrogen phosphate in a beaker containing 20mL deionized water, stir for 20min until it is fully dissolved, then slowly add the cooled mesophase liquid dropwise to the beaker, and stir for 30min after the addition is complete To the color is orange-yellow. Then put the beaker in a 65°C blast oven for 36 hours until it is completely dry. The precursor powder obtained after drying was placed in a nitrogen atmosphere at 350°C for 4 hours and 750°C for 8 hours. Get Na after cooling 3 V 2 (PO 4 ) 3 / C Compo...

Embodiment 3

[0024] Weigh 3mmol of sodium hydroxide, 2mmol of ammonium metavanadate, and 5mmol of hexamethylenetetramine in a small beaker containing 20mL of deionized water, and stir for 30min until it is fully dissolved; transfer the resulting mixed solution to the hydrothermal In the bladder, add deionized water to 80% of the volume of the inner bladder, and then hydrothermally heat it in a blast oven at 120°C for 24 hours and cool it naturally to obtain an intermediate liquid. Weigh 0.05g of sucrose and 6mmol of ammonium dihydrogen phosphate in a beaker containing 20mL of deionized water, stir for 20 minutes until it is fully dissolved, then slowly add the cooled mesophase liquid to the beaker, and stir for 30 minutes after the addition is complete To the color is orange-yellow. Then put the beaker in a 65°C blast oven for 36 hours until it is completely dry. The precursor powder obtained after drying was placed in a nitrogen atmosphere at 350°C for 4 hours and 750°C for 8 hours. Get ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com