Preparation method of Y molecular sieve catalyst with cordierite as carrier

A supported catalyst, cordierite technology, applied in molecular sieve catalysts, carbon monoxide or formate reaction preparation, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

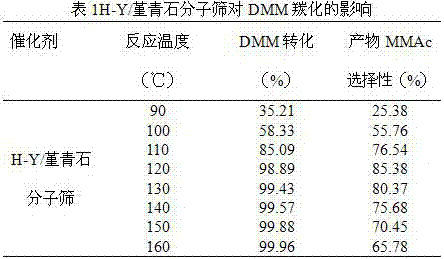

Embodiment 1

[0045] To pretreat the cordierite matrix, soak the cordierite in 2 mol L at room temperature -1 In the acid solution, after a certain period of time, the cordierite honeycomb ceramic matrix is prepared by drying and roasting. Place the fired cordierite honeycomb ceramic matrix in 2 mol L -1 SiO 2 In the gel, the silicon source was uniformly attached to the surface of the substrate by ultrasonic impregnation, the impregnation time was 0.5 h, dried at 120 °C, and calcined at 500 °C. The surface is attached with SiO 2 cordierite, NaAlO 2 , SiO 2 Gel, TPAOH and NaOH solution are fully stirred at room temperature for 1~2h according to a certain ratio. The solution was transferred to a stainless steel hydrothermal synthesis kettle with polytetrafluoroethylene lining, and crystallized at 120°C for 14 days. When the reaction time is up, the hydrothermal synthesis kettle is cooled to room temperature and the solution is suction filtered and washed with water until neutral. Dry...

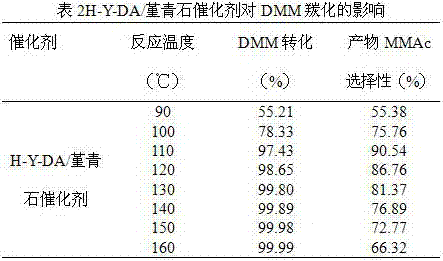

Embodiment 2

[0050] with H 4 EDTA solution removes Al from Y molecular sieve framework to prepare mesoporous H-Y / cordierite catalyst. Add 10 g of H-Y / cordierite catalyst to 200 mL with a concentration of 0.1 mol L -1 H 4 In the EDTA solution, react at 80 °C for 6 h, and then repeat the above steps after suction filtration and water washing until neutral, then place the molecular sieve in an oven to dry at 120 °C for 12 h, and then pass through a muffle furnace to bake at 550 °C for 5 h. h, the molecular sieve prepared at this time is recorded as H-Y-DA / cordierite.

[0051] In the fixed-bed reactor, 1.0 g of the catalysts prepared above were charged respectively, and the pressure in the reaction tube was 5.0 MPa. CO (99.9999%) with a flow rate of 50mL / min is mixed into the reaction tube through a stainless steel reaction tank filled with methylal (DMM) (98wt%) at room temperature (25°C), and the saturated vapor of DMM is mixed into the reaction tube by adjusting the back pressure valve ...

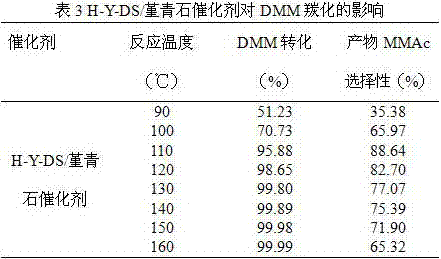

Embodiment 3

[0055]Mesoporous H-Y / cordierite catalyst was prepared by removing Si from molecular sieve framework with ammonia solution. Add 10 g of H-Y / cordierite catalyst to 120 mL with a concentration of 0.05 mol L -1 NH 4 In OH solution, react at room temperature for 1.0 h, then filter and wash with water to neutrality, place the molecular sieve in an oven for 120°C and dry it for 12 hours, then bake it in a muffle furnace at 550°C for 5h. The molecular sieve prepared at this time is marked as H-Y -DS / cordierite. In the fixed-bed reactor, 1 g of the above-mentioned catalysts were charged respectively, and the pressure in the reaction tube was 5 MPa. CO (99.9999%) with a flow rate of 50mL / min is mixed into the reaction tube through a stainless steel reaction tank filled with methylal (DMM) (98wt%) at room temperature (25°C), and the saturated vapor of DMM is mixed into the reaction tube by adjusting the back pressure valve To keep the reaction tube pressure constant. The reaction tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com