Mesoporous Zr-based coordination polymer and preparation method and application thereof

A coordination polymer and mesoporous technology, applied in water pollutants, other chemical processes, water/sludge/sewage treatment, etc., can solve problems such as difficulty in increasing the adsorption capacity of adsorbents, complicated preparation process, and environmental pollution. Achieve the effect of high yield, simple preparation method and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 0.114 grams of terephthalic acid and 0.16 grams of ZrCl 4 Disperse in 50 ml of polytetrafluoroethylene liner containing 20 ml of ultrapure water, then put it into a reaction kettle, and react in an oven at a reaction temperature of 120° C. for 24 hours. After the reaction, cool down to room temperature naturally, wash repeatedly three times with saturated triethylamine aqueous solution and absolute ethanol, and vacuum-dry in a vacuum oven at 60°C for 24 hours to obtain the Zr-based coordination polymer with an average pore size of 3.8 nm, the specific surface area is 157m 2 / g.

Embodiment 2

[0042] 0.114 grams of terephthalic acid and 0.055 grams of sodium hydroxide, and 0.16 grams of ZrCl 4 Dissolve each in 10mL of ultra-pure water, then mix the two solutions and stir well, then put them into a 50mL polytetrafluoroethylene liner and put them in a reaction kettle, and react in an oven at a reaction temperature of 120°C for 12h . After the reaction, cool down to room temperature naturally, then wash repeatedly with saturated triethylamine aqueous solution and ethanol several times, and vacuum-dry in a vacuum oven at 60°C for 24 hours to obtain the Zr-based coordination polymer with an average pore size of 3.7nm , the specific surface area is 135m 2 / g.

Embodiment 3

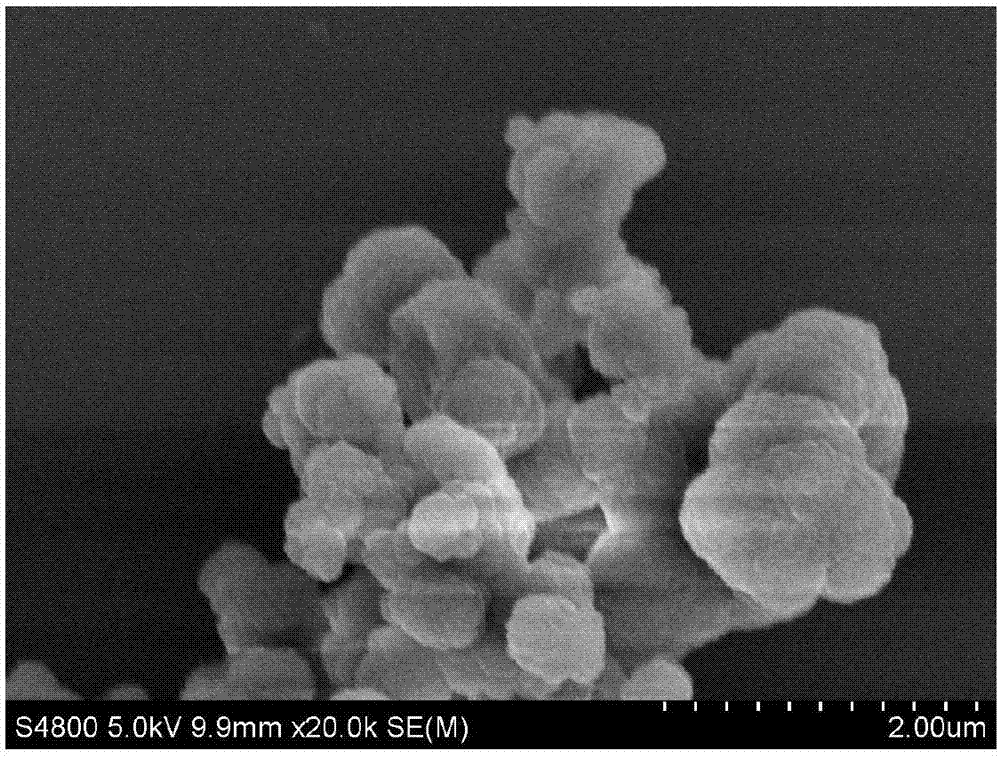

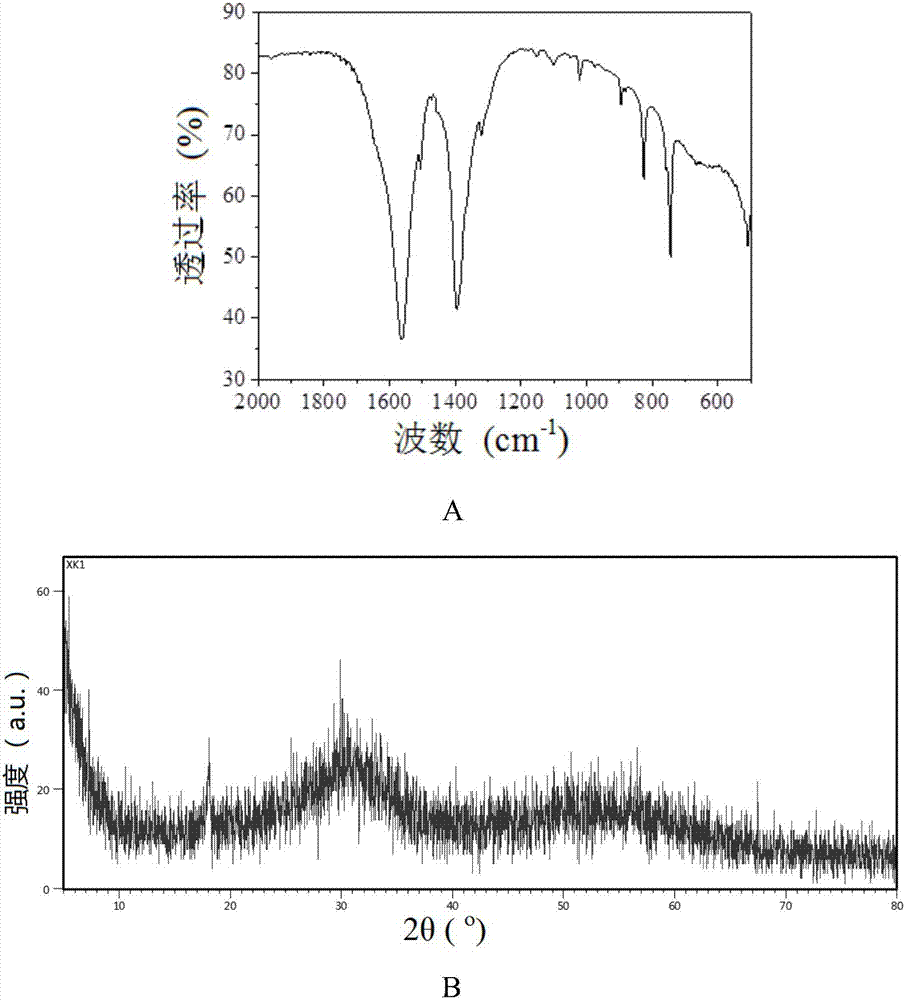

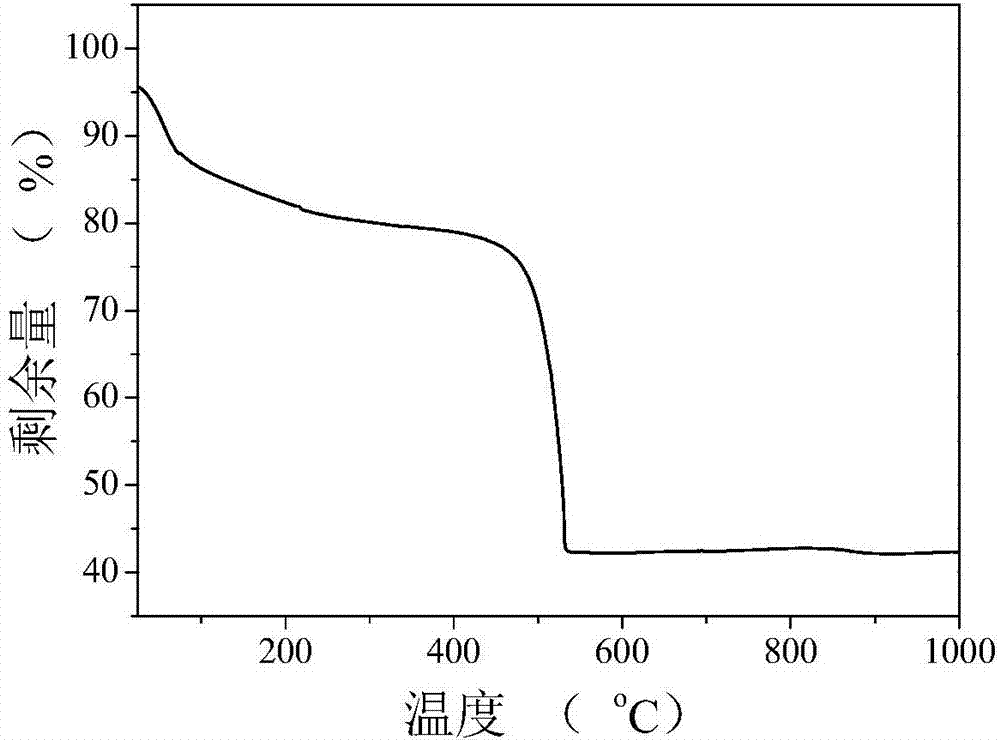

[0044] 0.114 grams of terephthalic acid and 0.055 grams of sodium hydroxide, and 0.16 grams of ZrCl 4 Each was dissolved in 10 mL of ultrapure water, and then the two solutions were mixed and fully stirred at room temperature for 24 h. After the reaction, it was naturally cooled to room temperature, then repeatedly washed with saturated triethylamine aqueous solution and ethanol for several times, and vacuum-dried in a vacuum oven at 60°C for 24 hours to obtain the Zr-based coordination polymer. Its scanning electron microscope picture The resulting product was shown to be an aggregate composed of 500 nm particles (see figure 1 ),Infrared spectra( figure 2 A) show that institute's product is terephthalic acid and ZrCl The coordination polymer that forms through coordination, powder X-ray diffraction pattern ( figure 2 B) shows that the product is amorphous, and the thermogravimetric curve ( image 3 ) shows that the ratio between terephthalic acid and Zr is about 1:1; N ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com