Composite fibrous membrane adsorbing heavy metals and preparation method thereof

A technology for composite fiber membranes and heavy metal adsorption, which is applied to alkali metal compounds, chemical instruments and methods, and adsorption water/sewage treatment. It can solve the problems of loss, low adsorption capacity of heavy metal ions, and small specific surface area of ordinary fibers. Long service life, excellent adsorption performance, good dissolution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

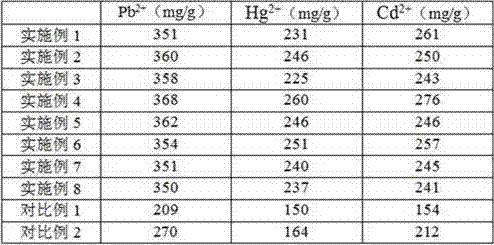

Examples

Embodiment 1

[0027] A composite fiber membrane for absorbing heavy metals, made of the following raw materials in parts by weight: 20 parts of bamboo fiber, 20 parts of polyacrylonitrile, 6 parts of porogen, 12 parts of chitosan, 3 parts of glutaraldehyde, styrene - 15 parts of divinylbenzene copolymer and 0.5 parts of benzoyl peroxide.

[0028] Wherein the porogen is polyethylene glycol.

[0029] A preparation method for a composite fiber membrane adsorbing heavy metals, comprising the following steps:

[0030] (1) Dissolve bamboo fiber, chitosan, polyacrylonitrile and styrene-divinylbenzene copolymer in 150 parts by weight of mixed solvent 1, and disperse ultrasonically. The ultrasonic dispersing power is 500W, and the time is 25min. silk stock solution;

[0031] (2) The spinning stock solution is subjected to electrospinning to obtain a spun fiber film, and the electrospinning conditions are as follows: a spinning distance of 10 cm, a voltage of 15 kV, and an extrusion speed of 5 mL / h...

Embodiment 2

[0035] A composite fiber membrane for absorbing heavy metals, made of the following raw materials in parts by weight: 22 parts of bamboo fiber, 19 parts of polyacrylonitrile, 7 parts of porogen, 11 parts of chitosan, 4 parts of glutaraldehyde, styrene - 14 parts of divinylbenzene copolymer and 0.6 parts of benzoyl peroxide.

[0036] Wherein the porogen is polyacrylamide.

[0037] A preparation method for a composite fiber membrane adsorbing heavy metals, comprising the following steps:

[0038] (1) Dissolve bamboo fiber, chitosan, polyacrylonitrile and styrene-divinylbenzene copolymer in 150 parts by weight of mixed solvent 1, and disperse ultrasonically. The ultrasonic dispersing power is 600W, and the time is 20min. silk stock solution;

[0039] (2) Electrospinning the spinning stock solution to obtain a spun fiber film, the electrospinning conditions are: spinning distance 11cm, voltage 16kV, extrusion speed 4mL / h;

[0040] (3) The spun fiber membrane is immersed in 56 p...

Embodiment 3

[0044] A composite fiber membrane for absorbing heavy metals, made of the following raw materials in parts by weight: 24 parts of bamboo fiber, 18 parts of polyacrylonitrile, 8 parts of porogen, 10 parts of chitosan, 5 parts of glutaraldehyde, styrene - 13 parts of divinylbenzene copolymer and 0.8 parts of benzoyl peroxide.

[0045] Wherein the porogen is polyethylene glycol.

[0046] A preparation method for a composite fiber membrane adsorbing heavy metals, comprising the following steps:

[0047] (1) Dissolve bamboo fiber, chitosan, polyacrylonitrile and styrene-divinylbenzene copolymer in 150 parts by weight of mixed solvent 1, and disperse ultrasonically. The ultrasonic dispersing power is 700W, and the time is 18min. silk stock solution;

[0048] (2) Electrospinning the spinning stock solution to obtain a spun fiber film, the electrospinning conditions are: spinning distance 12cm, voltage 18kV, extrusion speed 3mL / h;

[0049] (3) The spun fiber membrane is immersed in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com