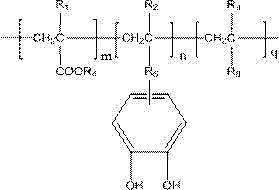

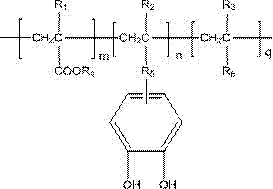

Silicon-containing acrylic resin based on catechol structural functionalization and preparation method and application thereof

A technology of silicic acrylic acid and catechol, applied in the direction of biocide-containing paints, coatings, antifouling/underwater coatings, etc., can solve the problem of weak substrate adhesion, unsatisfactory adhesion effect, and loss of antifouling effect and other problems, to achieve the effect of increasing the adhesion capacity, reducing the complexity and use cost, and being easy to mix and disperse.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A kind of functionalized silicon-containing acrylic resin based on catechol structure and preparation method and application thereof, comprising the following steps:

[0029]1) Equip the four-port reaction vessel with a stirrer, addition funnel, reflux condensing device, and thermometer respectively, add 25 parts of butanol and 30 parts of ethyl acetate, heat up to 100°C under stirring and keep it warm; then accurately weigh the methyl 30 parts of n-propyl acrylate, 4 parts of N-(3,4-dimethoxyphenyl) acrylamide, 25 parts of vinyltrimethoxysilane, 1.5 parts of diacetyl peroxide and uniformly mixed, the mixture was stabilized Add the drop rate into the four-port reaction vessel within 3 hours, continue to stir and keep warm for 2 hours to obtain the prepolymer; 2) Add 5 parts of hydrogen bromide aqueous solution to the prepolymer, heat and reflux for 1.5 hours and then change to distillation 3) Weigh 10 parts of functionalized silicon-containing acrylic resin based on cat...

Embodiment 2

[0031] A functionalized silicon-containing acrylic resin based on catechol structure and its preparation method and application, comprising the following steps:

[0032] 1) Prepolymerization: Add 40g of xylene and 8g of n-butanol into a four-necked reaction flask equipped with a stirrer, addition funnel, reflux condensing device, and thermometer, stir and heat up to 100-110°C and keep it warm. Then a homogeneous mixture of 4'-hydroxyl-3'-methoxyphenyl-2-propen-1-one, 32g methyl acrylate, 16g vinyltrimethoxysilane, 1.5g azobisisobutyronitrile was stabilized The dropping speed is added in the four-necked reaction flask within 4 hours, after continuing to stir and heat for 40 minutes, add dropwise a uniform mixture of 4g xylene, 4g n-butanol and 0.05g azobisisobutyronitrile in the four-necked flask within 1 hour. The mixture was continuously stirred and heated for 2 hours to obtain the prepolymer;

[0033] 2) Preparation: under stirring, add 10 g of hydrochloric acid to the prep...

Embodiment 3

[0036] A method for preparing a marine antifouling coating based on a catechol structure functionalized silicon-containing acrylic resin as a film-former, comprising the following steps:

[0037] Pre-polymerization: Equip the four-port reaction vessel with stirrer, liquid addition funnel, reflux condensing device, and thermometer, add 50 parts of xylene and 50 parts of butyl acetate, heat up to 100°C under stirring and keep it warm; then accurately weigh the formaldehyde 50 parts of butyl acrylate, 5 parts of N-(4-hydroxy-3-methoxyphenyl) acrylamide, 20 parts of acryloxypropyl trimethoxysilane, 2.0 parts of tert-butyl peroxybenzoate and Mix evenly, add the mixture into the four-port reaction vessel within 4 hours at a stable rate of addition, continue to stir and keep warm for 2 hours to obtain the prepolymer; introduce catechol structural functions into the side chain of the silicon-containing acrylic resin The chemical group increases the adhesion of the resin, reduces the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com