Pure organic homogeneous phase deposition method for preparing nanometer oxide under normal temperature

A nano-oxide, homogeneous deposition technology, applied in the direction of titanium oxide/hydroxide, oxygen/ozone/oxide/hydroxide, titanium dioxide, etc., can solve the problem of inability to show the preparation method, low cost, low energy consumption, etc. problems, to achieve high-efficiency photocatalytic activity, solve agglomeration, and controllable chemical composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

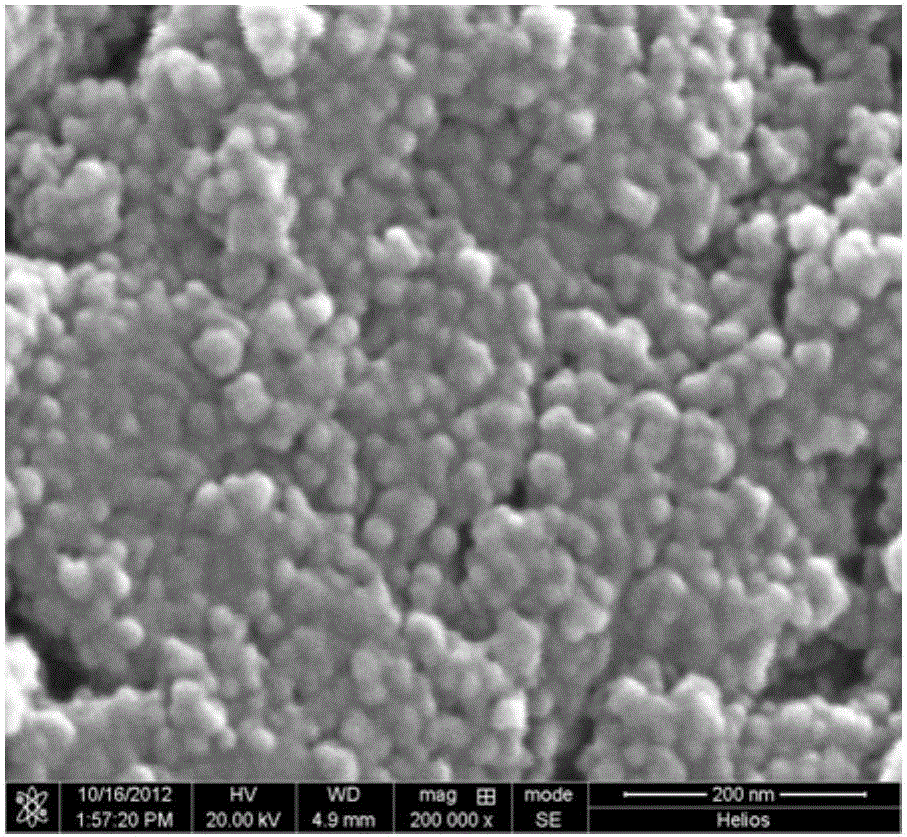

[0027] (1) Dissolve 10.98ml of titanium tetrachloride and 0.149g of triethanolamine in 15ml of absolute ethanol to make solution A, dissolve 20ml of formic acid solution in 15ml of alcohol to make solution B, mix A and B solutions, and keep stirring until the reaction A white cloudy precipitate produced. After aging at room temperature for 24 hours, after washing, centrifuge in a high-speed centrifuge at 1000r / min, pour off the supernatant, and repeat washing 3 times in this way. The washed precipitate was baked in an oven at 45°C for 24 hours and ground with a mortar to obtain nano-oxides. (2) Place the above-mentioned nano-oxide in a muffle furnace, program the temperature to 250° C. and calcinate for 6 hours to obtain nano-titanium dioxide powder.

Embodiment 2

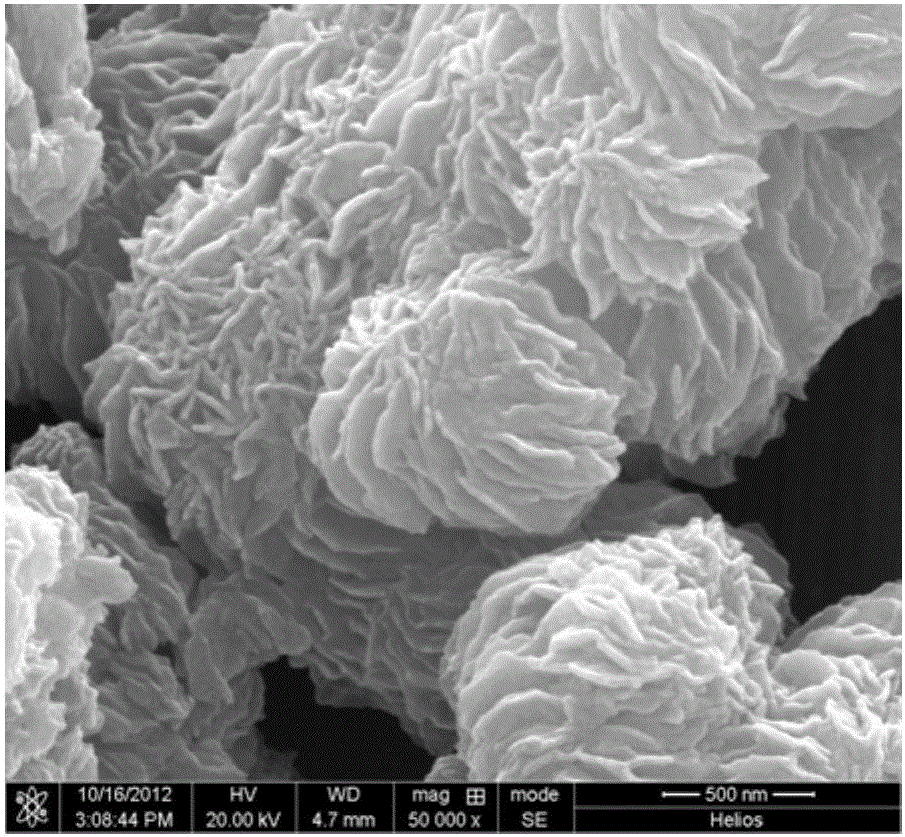

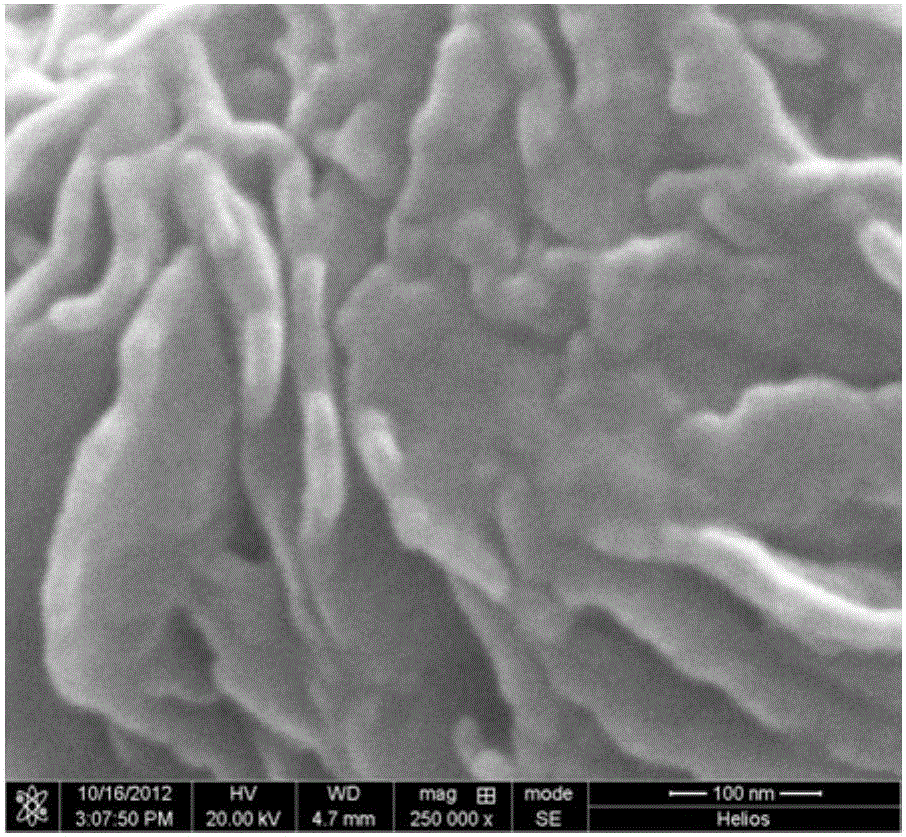

[0029] (1) Dissolve 10.98ml of titanium tetrachloride and 0.0745g of triethanolamine in 30ml of absolute ethanol to make solution A, dissolve 20ml of formic acid solution in 30ml of alcohol to make solution B, mix A and B solutions, and keep stirring until the reaction A white cloudy precipitate produced. After aging at room temperature for 24 hours, after washing, centrifuge in a high-speed centrifuge at 1000r / min, pour off the supernatant, and repeat washing 3 times in this way. The washed precipitate was baked in an oven at 45°C for 24 hours and ground with a mortar to obtain nano-oxides. (2) Put the above-mentioned nano-oxide in 0.018mol / L metaphosphoric acid solution and stir it fully to make it fully reacted, soak for 5 days after ultrasonication for 30 minutes, centrifuge, wash with deionized water for 3 times, and bake in an oven at 45°C for 24 hours to obtain the powder. It is a phosphorus-doped high-efficiency titanium dioxide nano-photocatalyst.

Embodiment 3

[0031] (1) Dissolve 21.96ml of titanium tetrachloride and 0.061g of monoethanolamine in 15ml of absolute ethanol to make solution A, dissolve 15ml of formic acid solution in 15ml of alcohol to make solution B, mix A and B solutions, and keep stirring until the reaction A white cloudy precipitate produced. After aging at room temperature for 24 hours, after washing, centrifuge in a high-speed centrifuge at 1000r / min, pour off the supernatant, and repeat washing 3 times in this way. The washed precipitate was baked in an oven at 45°C for 24 hours and ground with a mortar to obtain nano-oxides. (2) Place the above-mentioned nano-oxide in 0.02mol / L sodium hydroxide solution and stir well to make the reaction complete, soak for 5 days after ultrasonication for 30 minutes, centrifuge, wash with deionized water for 3 times, and bake in an oven at 45°C for 24 hours to obtain powder It is a new type of high-efficiency titanium dioxide nano-photocatalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com