Process for preparing hydroxylamine hydrochloride by adopting oxime acidolysis method

A technology for hydroxylamine hydrochloride and oximic acid is applied in the directions of oxime preparation, hydrolysis to prepare carbonyl compounds and hydroxylamine, etc., can solve problems such as high cost, harm the environment, uneconomical and the like, achieve less pollution, improve product yield and quality, and reduce production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Adopt the technology of oxime hydrolysis method to prepare hydroxylamine hydrochloride, it may further comprise the steps:

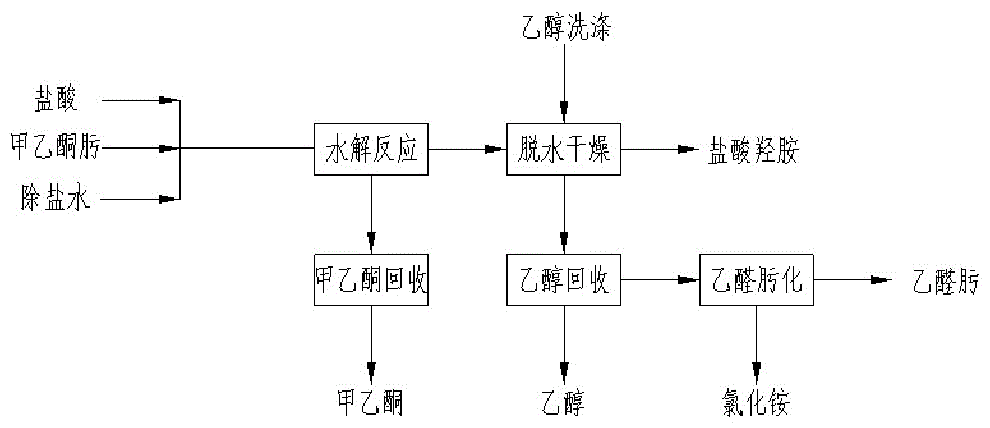

[0031] The process uses methyl ethyl ketone oxime and hydrochloric acid as raw materials, applies pervaporation-reaction coupling technology, and adopts oxime hydrolysis process to prepare hydroxylamine hydrochloride. It mainly includes raw material buffer configuration process, acid hydrolysis reaction process, ketoxime rectification process, dehydration and drying process, Ethanol recovery process, acetaldehyde oximation process and other sections.

[0032] Step a) Raw material buffer preparation process

[0033] The hydrochloric acid flows out from the storage tank and is pressurized by the pump, then enters the preparation tank, and is mixed with the recovered acid water to make a certain proportion of hydrochloric acid; after being heated by the heat exchanger through the pump, it enters the acidolysis kettle; Methyl ethyl ketone oxime enters...

Embodiment 2

[0046] The present invention investigates the effects of factors such as ketoxime type, feeding method, material ratio, material concentration, reaction temperature, and reaction time on the preparation of hydroxylamine hydrochloride by hydrolysis of ketoxime under normal pressure.

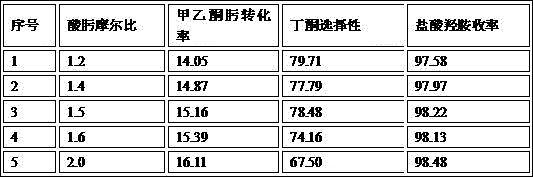

[0047] 1. Data analysis of the experimental process of the reaction behavior of hydroxylamine hydrochloride prepared by hydrolysis of oxime

[0048] ① Ketoxime selection

[0049] Hydrochloric acid with a mass concentration of 15% was prepared, and a certain amount of methyl ethyl ketone oxime and cyclohexanone oxime were weighed and reacted with hydrochloric acid at 80° C. at normal pressure for 1 hour. h + The molar ratio to ketoxime is 1.5. After the reaction, the conversion rate of ketoxime and the selectivity of hydroxylamine hydrochloride were analyzed and calculated, and the results are shown in Table 1 below.

[0050] Table 1 The reaction results of different ketoximes and hydrochloric a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com