Warm mixed colored asphalt, mixture containing same and preparation method thereof

A technology of modified asphalt and mixture, applied in building thermal insulation materials, building components, climate change adaptation and other directions, can solve the problems of high processing and use temperature, environmental pollution, etc., achieve low production and use temperature, low equipment investment, The effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

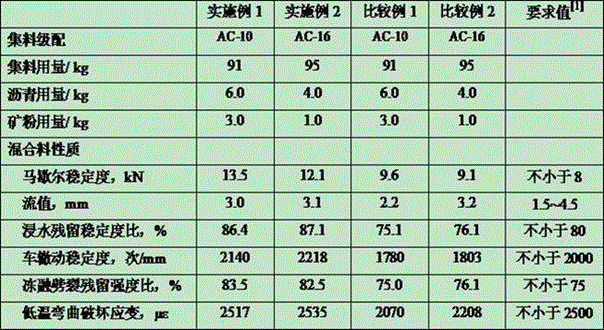

Examples

Embodiment 1

[0058] (1) Preparation of warm mix agent

[0059] (1) Preparation and loading

[0060] Put water under the sweating dish plate; connect the sealing system of the sweating dish with the pressurized buffer tank and the compressor; install the decompression buffer tank at the lower part of the sweating dish and connect the vacuum pump; connect the jacket of the sweating dish and the movable coil with the circulation system Connect, fix the coil on the sweating dish; start the heating function of the circulation system with heat transfer oil as the medium, so that the temperature of the circulating oil will rise to 94°C.

[0061] The polyethylene wax by-produced from the high-density polyethylene plant of PetroChina Jilin Petrochemical Ethylene Plant is used as raw material (drop melting point 90.3°C; 25°C penetration 43 dmm; 55°C penetration > 200 dmm, from 25°C and 55°C needles It can be seen that the polyethylene wax contains a large amount of low-melting point substances.), h...

Embodiment 2

[0075] (1) Preparation of warm mix agent

[0076] (1) Preparation and loading

[0077] Put water under the sweating dish plate. Connect the sealing system of the sweating dish with the pressurized buffer tank and the compressor; install the decompression buffer tank and connect the vacuum pump at the lower part of the sweating dish; connect the jacket of the sweating dish and the movable coil with the circulation system, and fix the coil in the On the sweating dish; using the heat transfer oil as the medium, start the heating function of the circulation system to raise the temperature of the circulation oil to 94°C.

[0078] Use the polyethylene wax by-produced by the high-density polyethylene plant of PetroChina Jilin Petrochemical Ethylene Plant as the raw material (the properties are the same as in Example 1), heat to 94°C and melt, then add dibenzoyl peroxide accounting for 0.03% of the weight of the raw material, and stir evenly Afterwards, add it to the sweating dish. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Drop melting point | aaaaa | aaaaa |

| Drop melting point | aaaaa | aaaaa |

| Penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com