Microbial fermented yellow distiller's grains feed for improving rumen protein utilization rate and preparation method

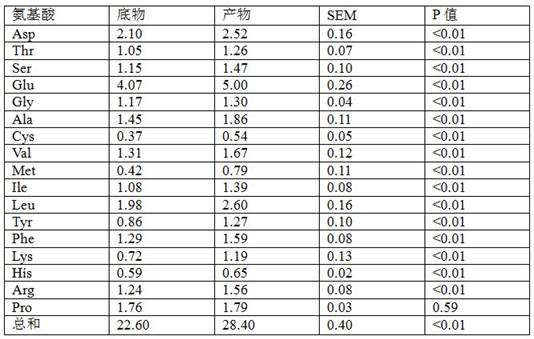

A technology of microbial fermentation and distiller's grains, which is applied in animal feed, animal feed, applications, etc., can solve the problems of low utilization rate of distiller's grains, improve utilization rate and digestibility, and increase the limiting amino acid lysine and methionine content, the effect of strong application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

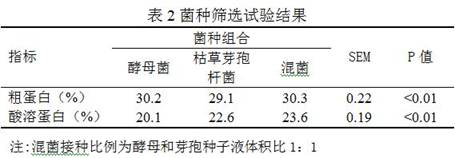

[0022] The preparation method of the fermented yellow distiller's grains feed comprises the following steps: use a pulverizer to pulverize the yellowish distiller's grains, bran, cassava dregs, and glucose, pass through a 1mm sieve, mix well, and then add an appropriate amount of water and 10% by mass The Bacillus subtilis and Candida utilis are mixed evenly, and the mixed bacteria are solid-state fermented for 44-48 hours under ventilation condition of 30-33° C., dried and pulverized to obtain microbial fermented distiller's grains feed.

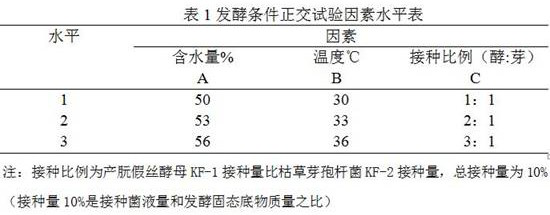

[0023] The specific process conditions of the preparation method are determined by orthogonal experiments.

[0024] Three factors that have a greater impact on the fermentation of rice distiller's grains were selected, and an orthogonal test analysis of three factors and three levels was carried out. The inoculation ratio, water content, and fermentation temperature were respectively used as optimization variables, and three repeated experim...

Embodiment 1

[0035] Bacillus subtilis and Candida utilis were inoculated into the seed medium shaker and cultured for 24 hours. After the rice distiller's grains, bran, cassava dregs, and glucose are pulverized respectively with a pulverizer, pass through a 1mm sieve, and mix evenly by weight percentage by 40% rice distiller's grains, 50% bran, 5% cassava dregs, and 5% glucose, and a total of 1.5 kg fermentation substrate; after cooling the sterilized feed, add 10% 2:1 (yeast: spore) mixed bacterial solution, and add appropriate amount of water at the same time, the water content of the solid-state fermentation substrate is controlled at 53%; the solid-state fermentation feed material layer The thickness is 8cm, cultivated at 33°C for 44 hours, cultivated for 12 hours, and turned over once; after the solid-state fermentation is completed, it is dried and pulverized, and dried at 65°C to keep the dry matter content at 88% to obtain the final product.

Embodiment 2

[0037] Bacillus subtilis and Candida utilis were inoculated into the seed medium shaker and cultivated for 24 hours; rice distiller's grains, bran, cassava dregs, and glucose were pulverized respectively with a pulverizer, and passed through a 1mm sieve, and the percentage by weight was 40 Mix % distiller's grains, 50% bran, 5% cassava residue, and 5% glucose to make a total of 1.5kg of fermentation substrate; after cooling the sterilized feed, add 10% of 2:1 (yeast: spore) mixed bacterial solution , while adding appropriate amount of water, the water content of the solid-state fermentation substrate is controlled at 50%; the thickness of the solid-state fermentation feed material layer is 12cm, cultivated at a constant temperature of 30°C for 44 hours, cultivated for 12 hours, and turned once; after the solid-state fermentation is completed, dry and pulverize , after drying at 65°C to keep the dry matter content at 88%, the final product was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com