Nanometer manganese catalyst for room-temperature catalytic oxidation of formaldehyde and preparation method thereof

A catalytic oxidation and nano-manganese technology, applied in chemical instruments and methods, separation methods, dispersed particle separation and other directions, can solve the problems of poor stability, short life of catalytic materials, and expensive active component gold, and achieve a simple preparation process, Easy operation and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A nano-manganese catalyst for catalytic oxidation of formaldehyde at room temperature, with alumina as a carrier. Concrete preparation steps are as follows:

[0029] (1) Weigh 0.4ml of polyethylene glycol with a density of 1.27 g / mL, dissolve it in 40 ml of deionized water with ultrasonic stirring, pour into 5g of activated alumina carrier, stir and impregnate for 0.5 h to prepare a mixed solution;

[0030] (2) Weigh 2.5 g of potassium permanganate, dissolve it in 40 ml of deionized water, add the potassium permanganate solution dropwise into the above mixed solution under stirring condition, and continue stirring for 2 h;

[0031] (3) Weigh 3.7 g of manganese sulfate, dissolve it in 20 ml of deionized water, add the manganese sulfate solution dropwise to the above mixed solution under stirring conditions, and continue stirring for 12 h to prepare the mixture solution;

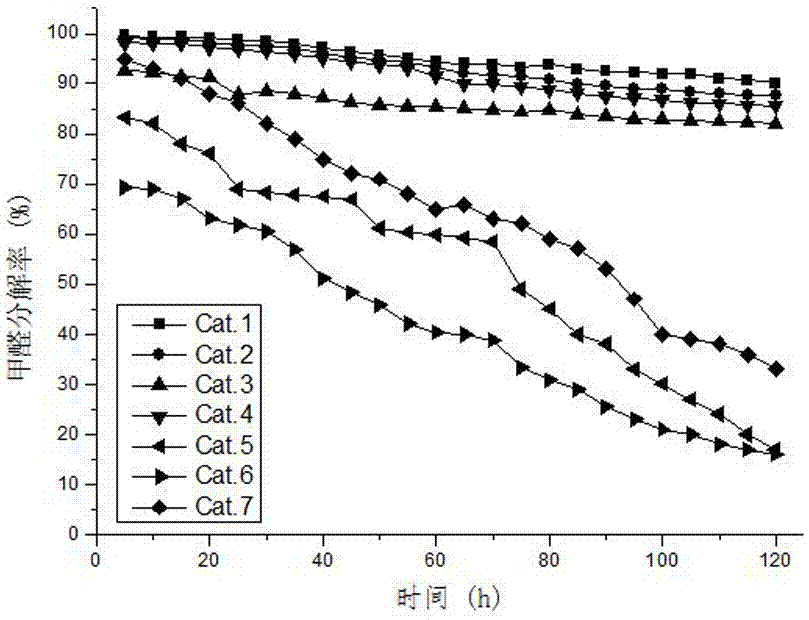

[0032] (4) The mixture solution is filtered, washed, 105 o Formaldehyde catalytic oxidation cataly...

Embodiment 2

[0034] A nano-manganese catalyst for catalytic oxidation of formaldehyde at room temperature uses pseudo-boehmite as a carrier. Concrete preparation steps are as follows:

[0035] (1) Weigh 0.5 g of cetyltrimethylammonium bromide, dissolve it in 40 ml of deionized water with ultrasonic stirring, pour into 5 g of pseudo-boehmite carrier and stir for 0.5 h to prepare a mixed solution;

[0036] (2) Weigh 2.5 g of potassium permanganate, dissolve it in 40 ml of deionized water, add the potassium permanganate solution dropwise into the above mixed solution under stirring condition, and continue stirring for 2 h;

[0037] (3) Weigh 3.9 g of manganese chloride, dissolve it in 20 ml of deionized water, add the manganese chloride solution dropwise to the above mixed solution under stirring conditions, and continue stirring for 12 h to obtain the mixture solution;

[0038] (4) The mixture solution is filtered, washed, 105 o Formaldehyde catalytic oxidation catalyst Cat.2 can be prepar...

Embodiment 3

[0040] A nano-manganese catalyst for catalytic oxidation of formaldehyde at room temperature uses zirconia as a carrier. Concrete preparation steps are as follows:

[0041] (1) Weigh 0.8 g of polyvinyl alcohol, dissolve it in 40 ml of deionized water with ultrasonic stirring, pour into 5 g of polyvinyl alcohol carrier and stir for 2 h to prepare a mixed solution;

[0042] (2) Weigh 2.5 g of potassium permanganate, dissolve it in 40 ml of deionized water, add the potassium permanganate solution dropwise into the above mixed solution under stirring condition, and continue stirring for 2 h;

[0043] (3) Weigh 3.1 g of manganese oxalate, dissolve it in 20 ml of deionized water, add the manganese chloride solution dropwise to the above mixed solution under stirring conditions, and continue stirring for 24 h to obtain the mixture solution;

[0044] (4) The mixture solution is filtered, washed, 120 o The formaldehyde catalytic oxidation catalyst Cat.3 can be obtained after drying i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com