Preparation method and application of biodegradable plastic thin film

A plastic film and biodegradation technology, applied in the field of preparation of biodegradable plastic films, can solve the problems of use, toxic and harmful catalysts, etc., and achieve the effects of easy operation, excellent degradable performance, and economical and accessible sources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

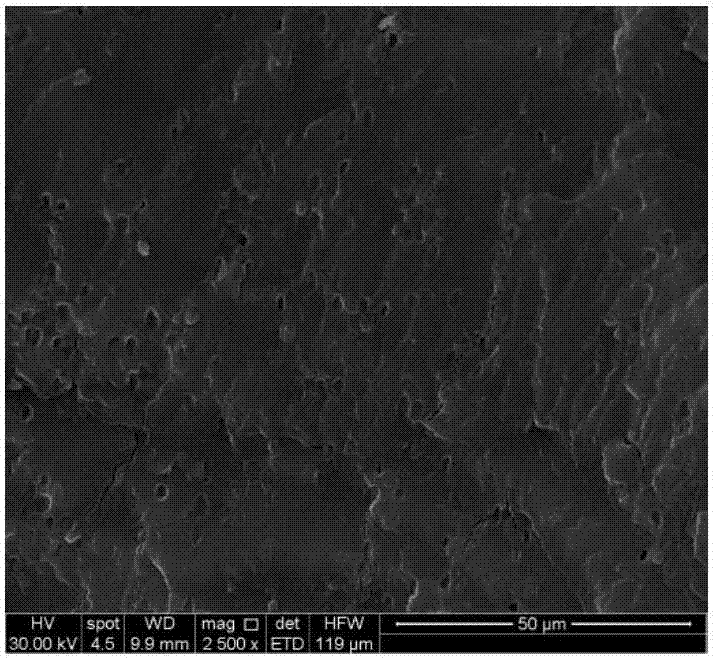

Image

Examples

preparation example Construction

[0025] A kind of preparation method of biodegradable plastic film of the present invention comprises the following steps:

[0026] 1) According to the mass ratio, add 0.1-20 parts of polyvinyl alcohol into 10-1000 parts of deionized water, stir at 80-120°C to dissolve completely, and obtain matrix A, which is cooled to room temperature for later use; Add 0.1-500 parts of natural polymer polysaccharide to 10-1000 parts of deionized water, stir at 10-100°C to dissolve completely, obtain matrix B, cool to room temperature for later use;

[0027] 2) At 60-100°C, slowly add (10-20 parts) B into (10-50 parts) A, continue to stir and heat until the mixture is uniform, and obtain matrix C, which is cooled to room temperature for later use; the stirring speed is 50-50 500r / min, the time is 1 to 12 hours.

[0028] 3) Mix 10-20 parts of matrix C, 0.5-20 parts of microorganisms, 0.01-10 parts of nutrient solution and 0.05-5 parts of pH regulator, and stir evenly at a temperature of 25-40...

Embodiment 1

[0031] Using natural polysaccharide compounds and polyvinyl alcohol compounds as raw materials, introducing fermented yeast as a degradation accelerator to prepare biodegradable plastic films, the preparation steps are:

[0032] In the first step, add 0.1 parts of polyvinyl alcohol into 10 parts of deionized water according to the mass ratio, stir at 80°C for 10 hours to dissolve it, and obtain matrix A; Cyclodextrin was added to 10 parts of deionized water and stirred at 10° C. for 0.1 hour to obtain matrix B.

[0033] In the second step, at 60°C, slowly add 10 parts of B to 10 parts of A, continue stirring and heating for 3 hours to make it uniform, and obtain matrix C.

[0034] In the third step, the prepared matrix C is cooled to room temperature, and 10 parts of matrix C, 0.5 part of fermenting yeast, 0.01 part of glucose, 0.01 part of peptone, 0.05 part of malic acid regulator, 0.05 part of sodium bicarbonate are taken, and the temperature is 25°C, stirring speed is 260...

Embodiment 2

[0036] Using natural polysaccharide compounds and polyvinyl alcohol compounds as raw materials, introducing fermented yeast as a degradation accelerator to prepare biodegradable plastic films, the preparation steps are:

[0037] In the first step, 0.1 parts of polyethylene glycol and 1.5 parts of polyvinyl alcohol are added to 100 parts of deionized water according to the mass ratio, and stirred at 90 ° C for 10 hours to obtain matrix A; the mass ratio of 1.5 parts Add modified starch and 1.5 parts of hydroxyethyl cellulose to 10 parts of deionized water, and stir at 70° C. for 0.6 hours to obtain matrix B.

[0038] In the second step, slowly add B into A at 80°C, and continue stirring and heating for 3 hours to obtain matrix C.

[0039] In the third step, the prepared base C is cooled to room temperature, and 15 parts of base C, 5 parts of fermented yeast, 0.5 part of glucose, 0.3 part of beef powder, 0.2 part of lactic acid, and 0.1 part of sodium carbonate are taken at a te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com