A preparation method of calcium phosphate nanopowder with controllable aspect ratio and calcium-phosphorus ratio

A nano-powder, calcium phosphate technology, applied in the field of calcium phosphate materials and their preparation, can solve the problems of limited application, serious product agglomeration, poor economy, etc., to improve the conversion rate and selectivity, efficiently control the nucleation process, The effect of reducing size and weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

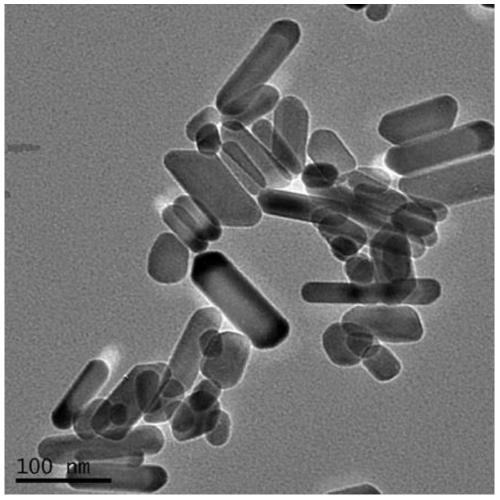

Embodiment 1

[0064] 1) Dissolve 4.72g of calcium nitrate tetrahydrate in 100ml of deionized water to prepare an aqueous solution of calcium nitrate, add 6g of urea to 20ml of deionized water to prepare a 5mol / L urea solution, prepare a 5mol / L ammonia solution, and add 2ml of the prepared ammonia solution is used as raw material A.

[0065] 2) Dissolve 1.584g of diammonium hydrogen phosphate in 60ml of water to prepare an aqueous solution of diammonium hydrogen phosphate, so that the ratio of calcium to phosphorus is 1.67, as raw material B.

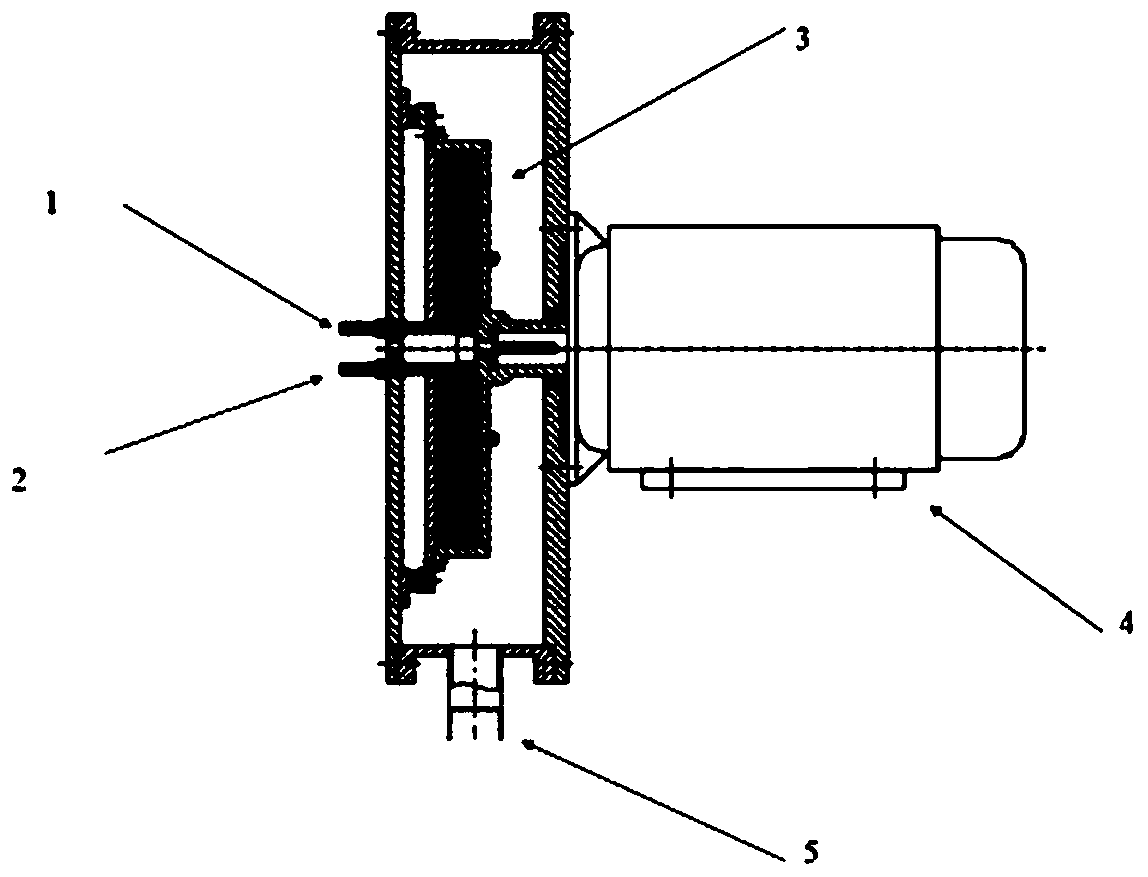

[0066]3) Turn on the supergravity rotation device and adjust the rotation speed to 2500rpm;

[0067] 4) Turn on the peristaltic pump, control the flow rate to be 0.2L / min and 0.12L / min respectively, and feed the two raw materials A and B into the high-gravity rotating bed by using the peristaltic pump, and keep the calcium-phosphorus ratio at 1.67 at the two feeding rates. Control the temperature of the reaction system at 25° C. to carry out the reac...

Embodiment 2

[0074] 1) Dissolve 4.72g of calcium nitrate tetrahydrate in 100ml of deionized water to prepare an aqueous solution of calcium nitrate, add 6g of urea to 20ml of deionized water to prepare a 5mol / L urea solution, prepare a 5mol / L ammonia solution, and add 1.5ml of prepared ammonia solution and 0.5ml of urea solution are used as raw material A.

[0075] 2) Dissolve 1.584g of diammonium hydrogen phosphate in 60ml of water to prepare an aqueous solution of diammonium hydrogen phosphate, so that the ratio of calcium to phosphorus is 1.67, as raw material B.

[0076] 3) Turn on the supergravity rotation device and adjust the rotation speed to 2500rpm;

[0077] 4) Turn on the peristaltic pump, control the flow rate to be 0.2L / min and 0.12L / min respectively, and feed the two raw materials A and B into the high-gravity rotating bed by using the peristaltic pump, and keep the calcium-phosphorus ratio at 1.67 at the two feeding rates. Control the temperature of the reaction system at 2...

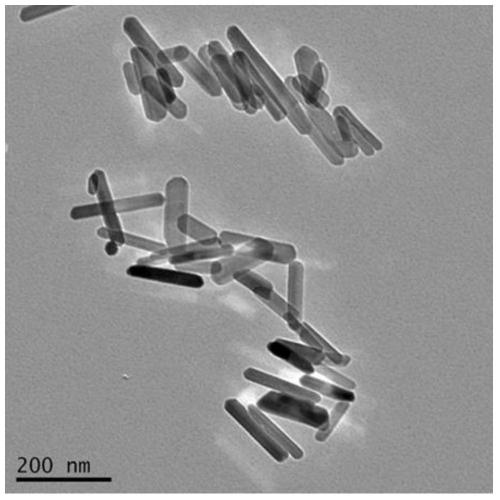

Embodiment 3

[0083] 1) Dissolve 4.72g of calcium nitrate tetrahydrate in 100ml of deionized water to prepare an aqueous solution of calcium nitrate, add 6g of urea to 20ml of deionized water to prepare a 5mol / L urea solution, prepare a 5mol / L ammonia solution, and add 1ml of prepared ammonia solution and 1ml of prepared urea solution are used as raw material A.

[0084] 2) Dissolve 1.584g of diammonium hydrogen phosphate in 60ml of water to prepare an aqueous solution of diammonium hydrogen phosphate, so that the ratio of calcium to phosphorus is 1.67, as raw material B.

[0085] 3) Turn on the supergravity rotation device and adjust the rotation speed to 2500rpm;

[0086] 4) Turn on the peristaltic pump, control the flow rate to be 0.2L / min and 0.12L / min respectively, and feed the two raw materials A and B into the high-gravity rotating bed by using the peristaltic pump, and keep the calcium-phosphorus ratio at 1.67 at the two feeding rates. Control the temperature of the reaction system...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com