Aluminum nitride ceramic plate metalization method

An aluminum nitride ceramic and sheet metal technology, applied in the field of ceramic metallization, can solve problems such as low yield and affect production quality, and achieve the effects of improving connection strength, product quality and yield, and product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

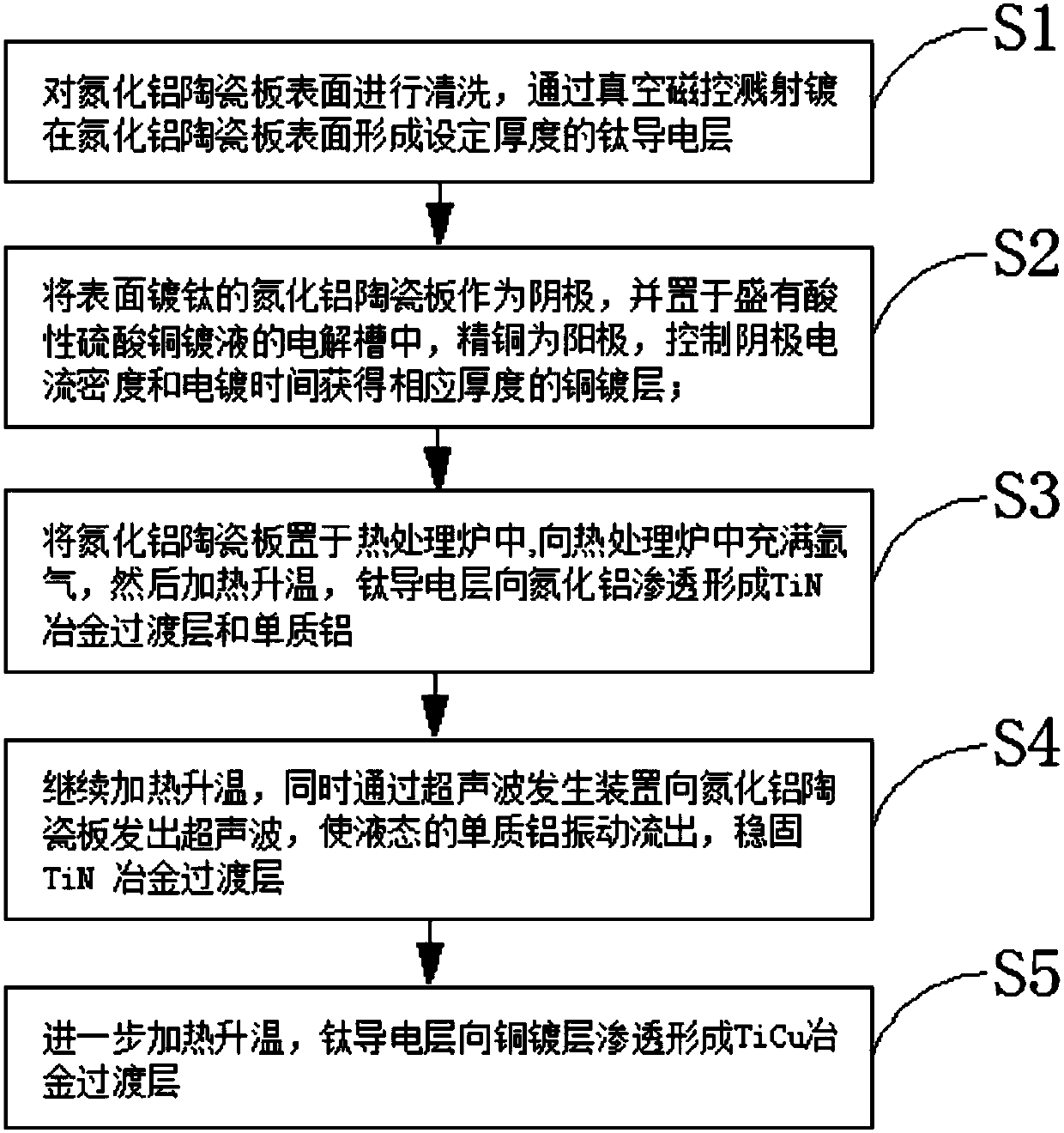

[0027] like figure 1 Shown, the method for metallizing an aluminum nitride ceramic plate comprises the following steps:

[0028] Step S1: Cleaning the surface of the aluminum nitride ceramic plate, first cleaning the surface of the aluminum nitride ceramic plate with 10% hydrochloric acid, then cleaning with water, and drying after cleaning; plating on nitrogen by vacuum magnetron sputtering A titanium conductive layer with a set thickness is formed on the surface of the aluminum ceramic plate;

[0029] Step S2: The titanium-plated aluminum nitride ceramic plate is used as the cathode, and placed in an electrolytic cell filled with acidic copper sulfate plating solution, refined copper is used as the anode, and the formula of the acidic copper sulfate plating solution is: 150g / L CuSO 4 ·5H 2 O, 50g / L mass concentration is 98% concentrated H 2 SO 4 , the solvent is water; control the cathode current density 3A / dm 2 1. The temperature is 30°C, and the time is 30 minutes, so...

Embodiment 2

[0035] like figure 1 Shown, the method for metallizing an aluminum nitride ceramic plate comprises the following steps:

[0036] Step S1: Cleaning the surface of the aluminum nitride ceramic plate, first cleaning the surface of the aluminum nitride ceramic plate with 10% hydrochloric acid, then cleaning with water, and drying after cleaning; plating on nitrogen by vacuum magnetron sputtering A titanium conductive layer with a set thickness is formed on the surface of the aluminum ceramic plate;

[0037] Step S2: The titanium-plated aluminum nitride ceramic plate is used as the cathode, and placed in an electrolytic cell filled with acidic copper sulfate plating solution, refined copper is used as the anode, and the formula of the acidic copper sulfate plating solution is: 180g / L CuSO 4 ·5H 2 O, 65g / L mass concentration is 98% concentrated H 2 SO 4 , the solvent is water; control the cathode current density 5A / dm 2 1. The temperature is 40°C, and the time is 20 minutes, so...

Embodiment 3

[0043] like figure 1 Shown, the method for metallizing an aluminum nitride ceramic plate comprises the following steps:

[0044] Step S1: Cleaning the surface of the aluminum nitride ceramic plate, first cleaning the surface of the aluminum nitride ceramic plate with 10% hydrochloric acid, then cleaning with water, and drying after cleaning; plating on nitrogen by vacuum magnetron sputtering A titanium conductive layer with a set thickness is formed on the surface of the aluminum ceramic plate;

[0045] Step S2: The titanium-plated aluminum nitride ceramic plate is used as the cathode, and placed in an electrolytic cell filled with acidic copper sulfate plating solution, refined copper is used as the anode, and the formula of the acidic copper sulfate plating solution is: 220g / L CuSO 4 ·5H 2 O, 80g / L mass concentration is 98% concentrated H 2 SO 4 , the solvent is water; control the cathode current density 8A / dm 2 1. The temperature is 50°C, and the time is 10 minutes, so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com