A kind of hyperbranched polysiloxane and preparation method thereof

A technology of polysiloxane and propyltriethoxysilane, applied in the field of hyperbranched polysiloxane and its preparation, can solve the problems of harsh conditions, high self-polymerization temperature of alkynyl groups, use of flame retardants, etc. Excellent heat resistance and rigidity, good processability, easy reaction temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

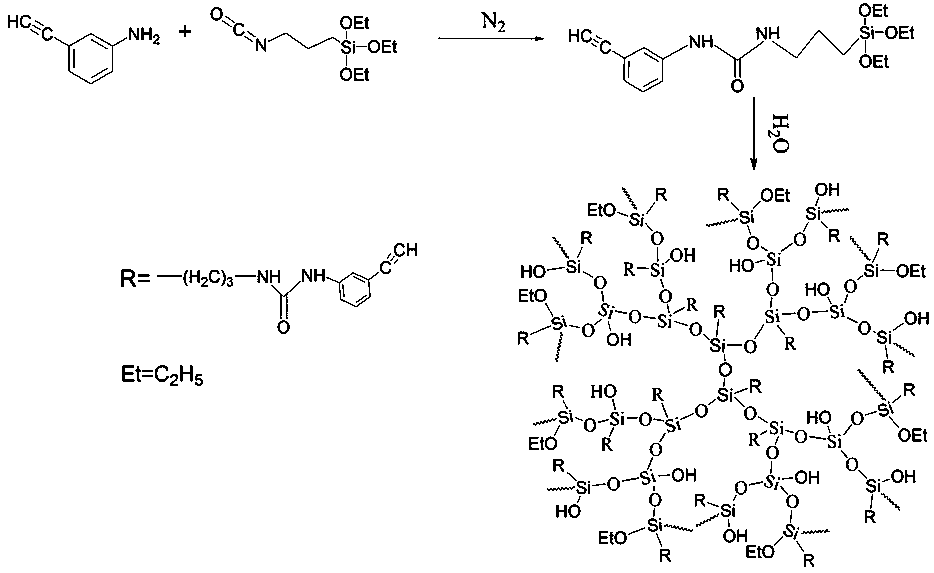

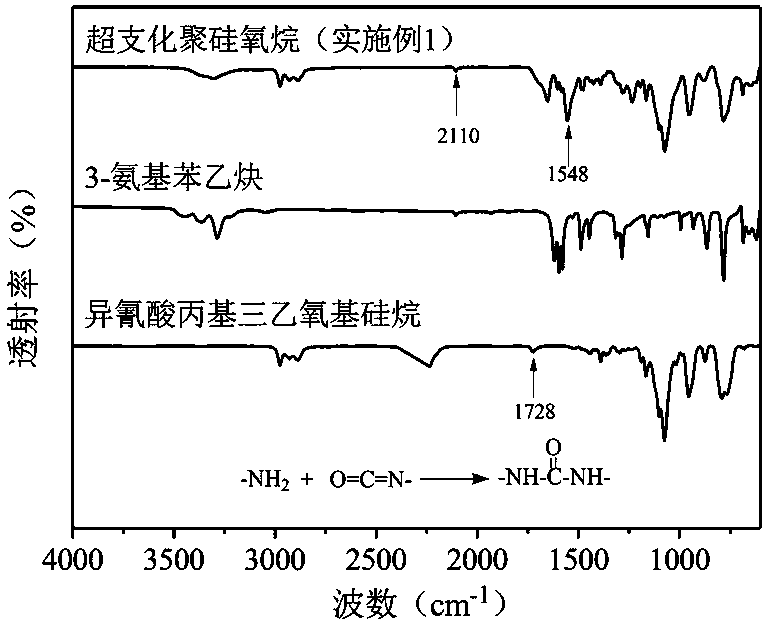

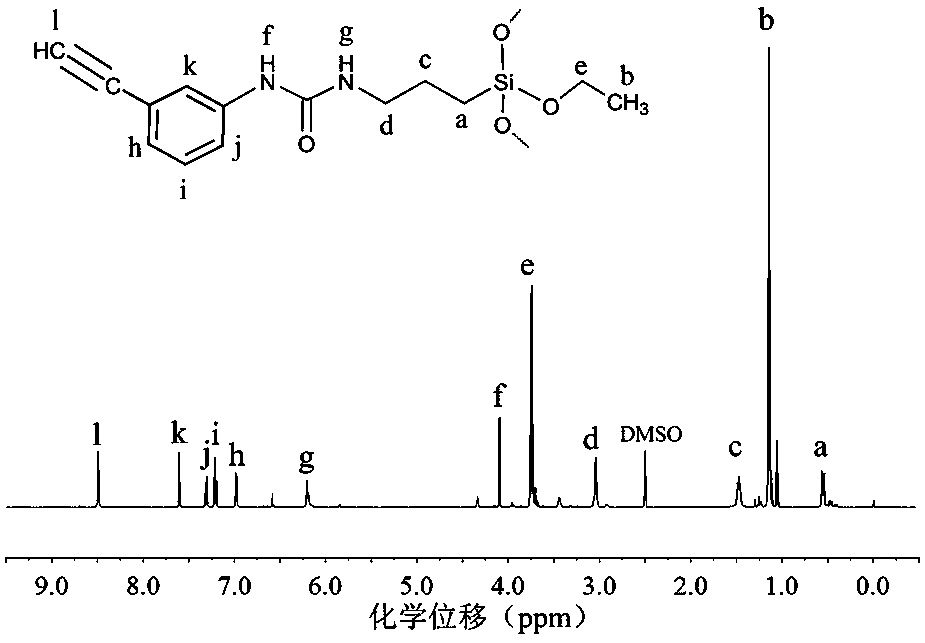

[0038] See attached figure 1 , which is a schematic diagram of the synthesis principle of hyperbranched polysiloxane provided in this example; the synthesis of hyperbranched polysiloxane mainly includes two steps: the first step is isocyanate propyltriethoxysilane and 3-amino Phenylacetylene reaction; the second step is the generation of hyperbranched structure. Concrete process conditions and steps are as follows:

[0039] 1. Add 0.1mol of 3-aminophenylacetylene and 0.1mol of isocyanate propyltriethoxysilane into a flask containing 20mol of toluene; react at 60°C for 12h under nitrogen protection and magnetic stirring; spin Intermediate A was obtained after removal of the solvent by evaporation.

[0040] 2. Dissolve intermediate A in 20 mol of ethanol and put it in a flask, then add 0.102 mol of water into the flask, react at 60°C for 6 hours; then evaporate the solvent at 40°C, wash the product several times with ethanol, Product B is obtained. Product B was vacuum-dried...

Embodiment 2

[0066] Add 0.1mol of 3-aminophenylacetylene and 0.1mol of isocyanatopropyltriethoxysilane into a flask containing 10mol of carbon tetrachloride, and react at 100°C for 24h under nitrogen protection and magnetic stirring; Intermediate A was obtained after pressure distillation to remove the solvent. Dissolve intermediate A in 10 mol of methanol, then add 0.12 mol of water into the flask, react at 80°C for 12h; then remove the solvent at 40°C, wash the product several times with methanol to obtain product B. The product B was vacuum-dried at 80° C. for 12 hours to obtain a yellow liquid, which was hyperbranched polysiloxane.

Embodiment 3

[0068] Add 0.1 mol of 3-aminophenylacetylene and 0.1 mol of isocyanatopropyltriethoxysilane to a flask containing 40 mol of chloroform, and react at 60°C for 8 hours under argon protection and magnetic stirring; rotary evaporation method After removal of the solvent, intermediate A is obtained. Intermediate A was dissolved in 40 mol of propanol, then 0.2 mol of water was added to the flask, and reacted at 40°C for 4 hours; then the solvent was evaporated at 40°C, and the product was washed several times with propanol to obtain product B. The product B was vacuum-dried at 40° C. for 4 hours to obtain a yellow liquid, which was hyperbranched polysiloxane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com