Production method for high-performance polyphthalamide long-fiber coating reinforcing material

A polyphthalamide, reinforcing material technology, applied in the coating and other directions, can solve the problems of poor flame retardant performance and antistatic performance, PPA toughness and rigidity can not have both, can not be widely used and other problems, to achieve thermal stability. Good stability, low price, excellent antistatic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

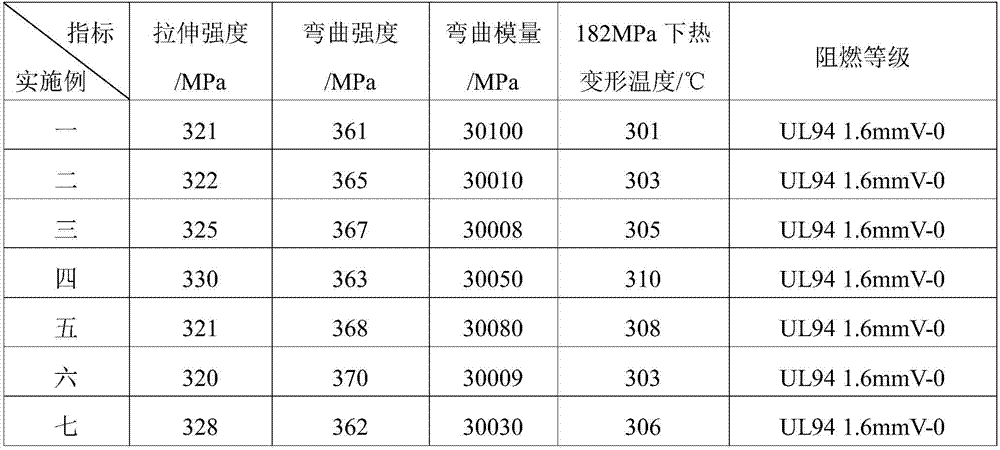

Examples

Embodiment 1

[0027] The invention discloses a production method of a high-performance polyphthalamide filament-coated reinforcing material, which specifically includes the following steps:

[0028] Step 1, in parts by weight, successively weigh 100 parts of polyphthalamide, 80 parts of long fiber, 50 parts of ammonium polyphosphate, 35 parts of PTFE wax micropowder, 15 parts of KH-550, 15 parts of tri(2, 4-di-tert-butylphenyl) phosphite, 9 parts of maleic anhydride grafted polyolefin elastomer and 10 parts of dodecyl dimethyl betaine, and carry out drying treatment; Phthalamide is dried, the dew point temperature is -40°C, the drying temperature is 130°C, and the drying time is 5-6 hours. The drying temperature of the long fiber is 130°C, and the long fiber is ECT5301HP;

[0029] Step 2, the dried ammonium polyphosphate, PTFE wax powder, KH-550, three (2,4-di-tert-butylphenyl) phosphite, maleic anhydride grafted polyolefin elastomer, dodecyl Add dimethyl betaine and polyphthalamide accoun...

Embodiment 2

[0032] The invention discloses a production method of a high-performance polyphthalamide filament-coated reinforcing material, which specifically includes the following steps:

[0033] Step 1, in parts by weight, successively weigh 100 parts of polyphthalamide, 50 parts of long fibers, 30 parts of ammonium polyphosphate, 20 parts of modified molybdenum disulfide, 12 parts of KH-570, 13 parts of four ( 2,4-di-tert-butylphenyl-4,4-biphenyl)bisphosphate, 8 parts of maleic anhydride grafted polyolefin elastomer and 2 parts of polyoxyethylene stearate, and dried; The polyphthalamide is dried using a dehumidification drying method, the dew point temperature is -40°C, the drying temperature is 130-140°C, the drying time is 5-6 hours, and the drying temperature of the long fibers is 120-130°C. ℃, the long fiber is ECT5301HP;

[0034] Step 2, the dried ammonium polyphosphate, modified molybdenum disulfide, KH-570, tetrakis (2,4-di-tert-butylphenyl-4,4-biphenyl) bisphosphate, maleic an...

Embodiment 3

[0037] The invention discloses a production method of a high-performance polyphthalamide filament-coated reinforcing material, which specifically includes the following steps:

[0038] Step 1. According to parts by weight, weigh 100 parts of polyphthalamide, 60 parts of long fiber, 40 parts of ammonium polyphosphate, 35 parts of PTFE wax micropowder, 10 parts of KH-550, 5 parts of N, N' - bis-(3-(3,5-di-tert-butyl-4-hydroxyphenyl) propionyl) hexamethylenediamine, 6 parts of maleic anhydride grafted polyolefin elastomer and 5 parts of dodecyldimethyl Betaine, and drying treatment, the long fiber is ECT5301HP; polyphthalamide is dried by dehumidification drying method, the dew point temperature is -40°C, the drying temperature is 140°C, and the drying time is 5 to 6 hours. The drying temperature of the long fibers was 120°C.

[0039]Step 2, the dried ammonium polyphosphate, PTFE wax powder, KH-550, N, N'-bis-(3-(3,5-di-tert-butyl-4-hydroxyphenyl) propionyl) hexadiene Amine, ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com