The preparation method of 2-isopropylthioxanthone

A technology of isopropylthioxanthone and isopropylbenzophenone, which is applied in the field of preparation of high-efficiency ultraviolet photoinitiator 2-isopropylthioxanthone, can solve the problem of reducing photoinitiation efficiency and the amount of concentrated sulfuric acid Solve the problems of large waste acid and low product yield, and achieve the effect of convenient and easy solvent recovery, short production cycle and high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

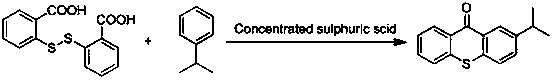

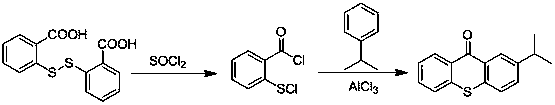

Problems solved by technology

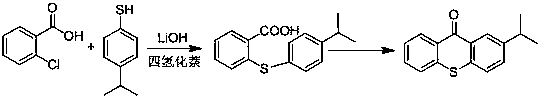

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1: Preparation method of 2-isopropylthioxanthone

[0043] 1) Dissolve 28.9g (0.10mol) 2-chloro-2'-methoxy-5'-isopropylbenzophenone in 80mL toluene, add 0.6g (0.01mol) copper powder, 7.0g (0.22 mol) sulfur powder and 24.4g (0.23mol) sodium carbonate, stir evenly, heat to reflux for reaction, TLC or liquid chromatography to monitor the reaction, after the reaction, start to cool down;

[0044] 2) After step 1) drops to room temperature, first filter the insoluble matter in the system, add 80mL water to the filtrate, wash with water, and recover the solvent from the organic phase, then add 50mL methanol to the residue for recrystallization, and obtain 20.3g light yellow The solid, namely: 2-isopropylthioxanthone, has a content of 99.0% and a melting point of 75-77°C.

Embodiment 2

[0045] Embodiment 2: Preparation of 2-isopropylthioxanthone

[0046] 1) Dissolve 28.9g (0.10mol) 2-chloro-2'-methoxy-5'-isopropylbenzophenone in 90mL chlorobenzene, add 0.6g (0.01mol) copper powder, 7.0g ( 0.22mol) sulfur powder and 24.4g (0.23mol) sodium carbonate, stir evenly, heat to reflux for reaction, TLC or liquid chromatography to monitor the reaction, after the reaction, start to cool down;

[0047] 2) After step 1) is lowered to room temperature, first filter the insoluble matter in the system, add 80 mL of water to the filtrate, wash with water, and recover the solvent from the organic phase, then add 50 mL of methanol to the residue for recrystallization, and obtain 21.0 g of light yellow The solid, namely: 2-isopropylthioxanthone, has a content of 99.0% and a melting point of 75-77°C.

Embodiment 3

[0048] Embodiment 3: Preparation of 2-isopropylthioxanthone

[0049] 1) Dissolve 30.3g (0.10mol) 2-chloro-2'-ethoxy-5'-isopropylbenzophenone in 60mL dichloroethane, add 0.6g (0.01mol) copper powder, 7.0 g (0.22mol) of sulfur powder and 24.4g (0.23mol) of sodium carbonate, stir evenly, heat to reflux for reaction, monitor the reaction by TLC or liquid chromatography, and start to cool down after the reaction;

[0050] 2) After step 1) is lowered to room temperature, first filter the insoluble matter in the system, add 80 mL of water to the filtrate, wash with water, and recover the solvent from the organic phase, then add 50 mL of methanol to the residue for recrystallization, and obtain 20.8 g of light yellow The solid, namely: 2-isopropylthioxanthone, has a content of 99.3% and a melting point of 75-77°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com