High-density grafted acid-based anti-biofilm material for catalyzing bacterial lysis and its preparation method and application

An anti-biological, high-density technology, which is applied in antibacterial, anti-corrosion materials, and super-hydrophilic fields. It can solve the problems of organic quaternary ammonium salts and metal ions with high biological toxicity and unfriendly environment, so as to avoid embedding antibiotics and reduce antibiotic resistance. Medicinal properties and low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] 1. Antibacterial latex catheter

[0027] Step 1, the medical latex guide (1-4 cm length, 1 mm inner diameter) tube is cleaned with ethanol and dried;

[0028] Step 2, the latex catheter is placed in the plasma generator, vacuumized, and then argon gas is introduced into the reaction chamber (less than 400 millitorr, 2.4 cubic meters per hour), and the plasma excitation is started (output power 80 watts, 3 minutes);

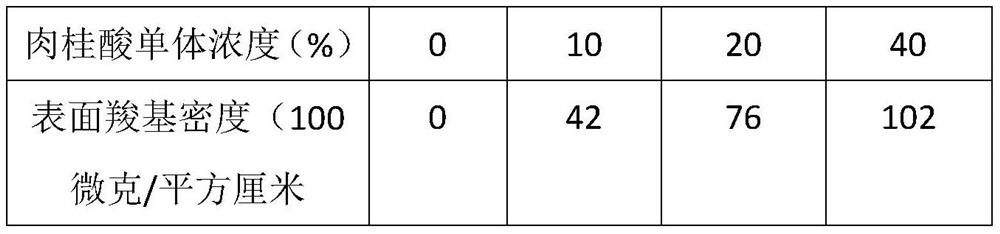

[0029] Step 3, placing the plasma-activated latex catheter in air for 70 minutes to generate active reaction centers, and then placing the latex catheter in a pre-deoxidized container containing 40% acrylic acid solution, and sealing it;

[0030] Step 4, the polymerization reaction is carried out under anaerobic conditions, the temperature is maintained at 70 degrees, and the reaction is carried out for 12 hours;

[0031] Step 5, after the reaction, the latex catheter is washed with water, 30% sodium hydroxide, purified water, and ethanol in an ultrasonic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com