A kind of preparation method of positive pole plate of lead-carbon battery

A lead-carbon battery and positive electrode technology, applied in the direction of lead-acid battery electrodes, etc., can solve the problems of ignoring the mass transfer and diffusion of the plate, and achieve the effects of improving charge and discharge acceptance, prolonging cycle life, and improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

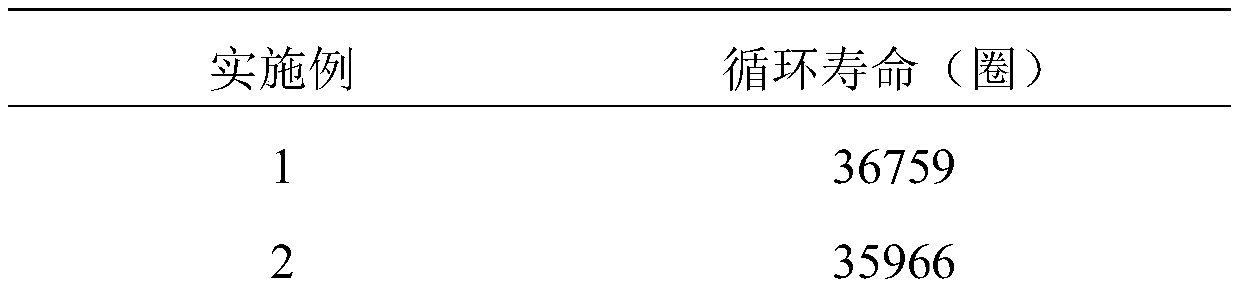

Embodiment 1

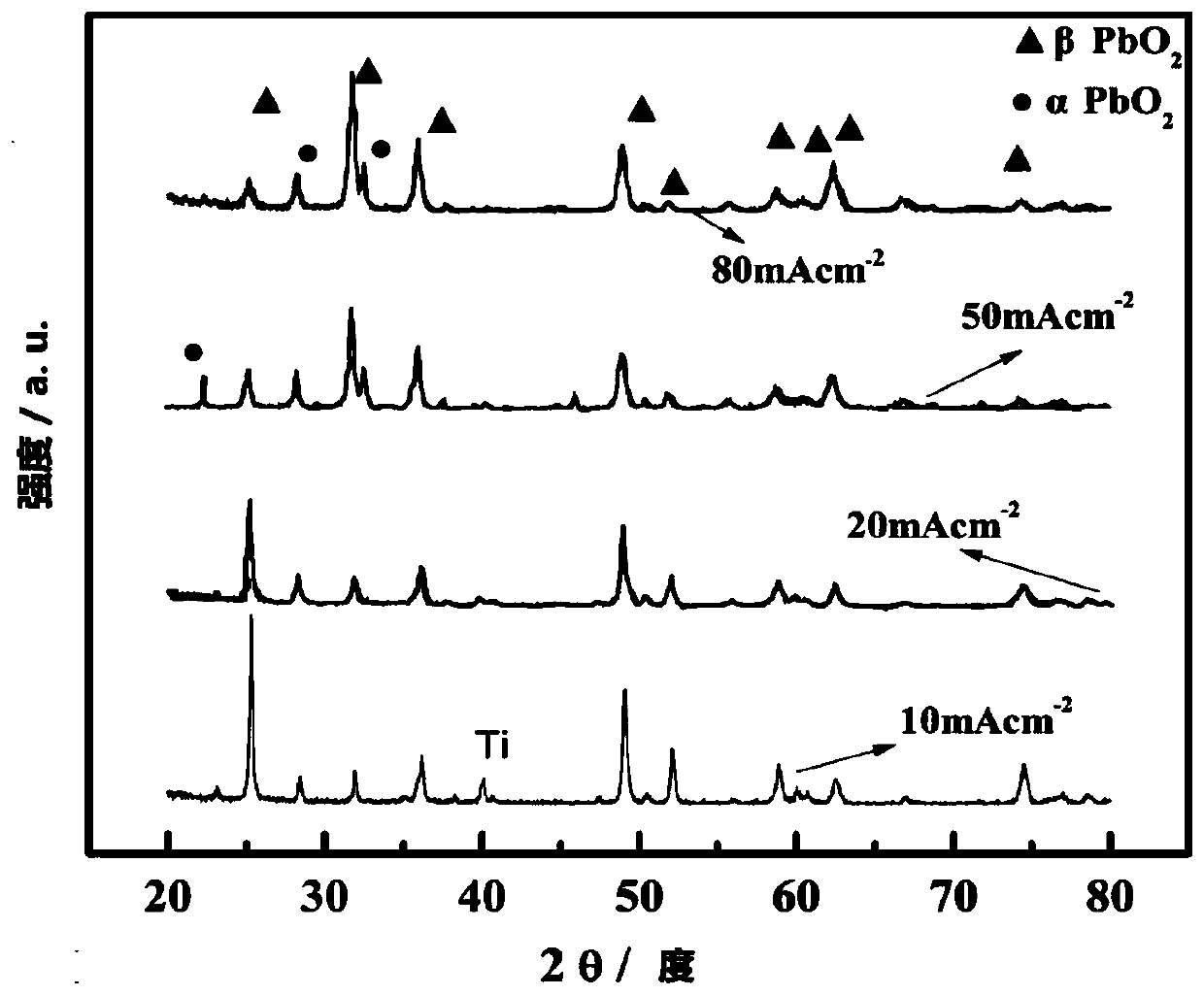

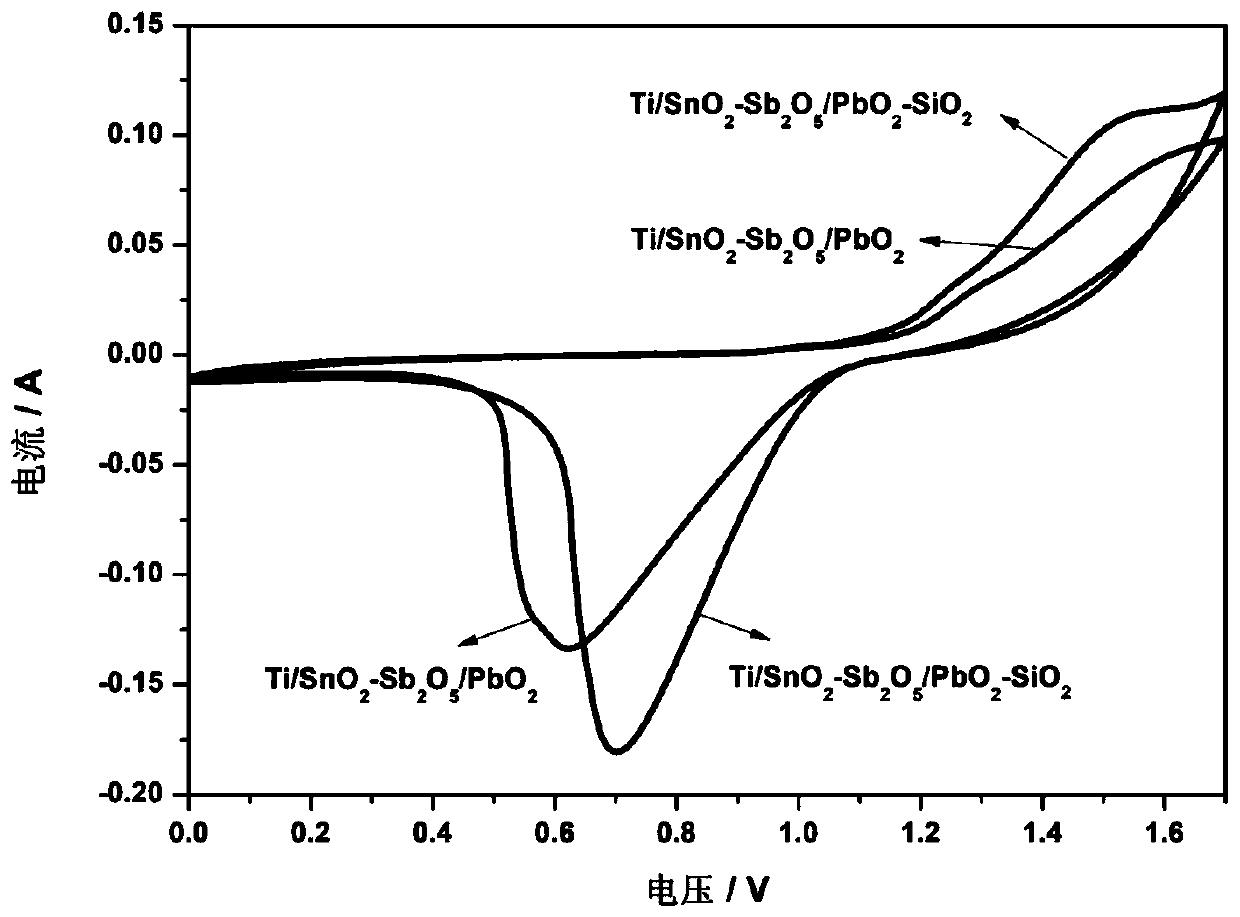

[0032] Using the constant current deposition method, the flat titanium is placed in 1M lead sulfate, 0.1M sulfuric acid, 0.05M nano-SiO 2 , 0.05M triethylhexyl phosphoric acid mixed solution, the counter electrode is a platinum electrode, and the deposition current density is 10mA / cm 2 , the deposition time is 4h, the deposition temperature is 25℃, and the α / β-PbO 2 -SiO 2 Complex.

[0033] 85wt% lead powder, 10wt% α / β-PbO 2 -SiO 2 Compound, 2.5wt% of colloidal graphite, 2.5wt% of 40mm polyester are mixed evenly to make active substance, and the mixed active substance is slowly added with 12wt% of its total weight of water and 8wt% of sulfuric acid of 2mL / s 4.7mol / L stirring evenly to form a lead paste; coating the prepared lead paste on a lead alloy grid, drying and solidifying to prepare a positive electrode plate of a lead-carbon battery. The curing steps are as follows:

[0034] 1) 55°C, air humidity 98%, constant temperature for 2h

[0035] 2) 60℃, air humidity 95%...

Embodiment 2

[0040] Using the constant current deposition method, the flat titanium is placed in 1M lead sulfate, 0.1M sulfuric acid, 0.05M nano-SiO 2 , 0.05M triethylhexyl phosphoric acid mixed solution, the counter electrode is a platinum electrode, and the deposition current density is 20mA / cm 2 , the deposition time is 4h, the deposition temperature is 25℃, and the α / β-PbO 2 -SiO 2 Complex.

[0041] 85wt% lead powder, 10wt% α / β-PbO 2 -SiO 2 Compound, 2.5wt% of colloidal graphite, 2.5wt% of 40mm polyester are mixed evenly to make active substance, and the mixed active substance is slowly added with 12wt% of its total weight of water and 8wt% of sulfuric acid of 2mL / s 4.7mol / L stirring evenly to form a lead paste; coating the prepared lead paste on a lead alloy grid, drying and solidifying to prepare a positive electrode plate of a lead-carbon battery. The curing steps are as follows:

[0042] 1) 55°C, 98% air humidity, constant temperature for 3 hours

[0043] 2) 60°C, air humidity...

Embodiment 3

[0048] Using the constant current deposition method, the flat titanium is placed in 1M lead sulfate, 0.1M sulfuric acid, 0.05M nano-SiO 2 , 0.05M triethylhexyl phosphoric acid mixed solution, the counter electrode is a platinum electrode, and the deposition current density is 50mA / cm 2 , the deposition time is 4h, the deposition temperature is 30℃, and the α / β-PbO 2 -SiO 2 Complex.

[0049] 85wt% lead powder, 10wt% α / β-PbO 2 -SiO 2 Compound, 2.5wt% of colloidal graphite, 2.5wt% of 40mm polyester are mixed evenly to make active substance, and the mixed active substance is slowly added with 12wt% of its total weight of water and 8wt% of sulfuric acid of 2mL / s 4.7mol / L stirring evenly to form a lead paste; coating the prepared lead paste on a lead alloy grid, drying and solidifying to prepare a positive electrode plate of a lead-carbon battery. The curing steps are as follows:

[0050] 1) 55°C, air humidity 98%, constant temperature for 4h

[0051] 2) 60℃, air humidity 98%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com