Preparation method for battery negative electrode and conductive agent material used for lithium ion battery

A lithium-ion battery and battery negative electrode technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of single pore size distribution, poor conductivity, complex process, etc., achieve low price, improve rate performance, and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

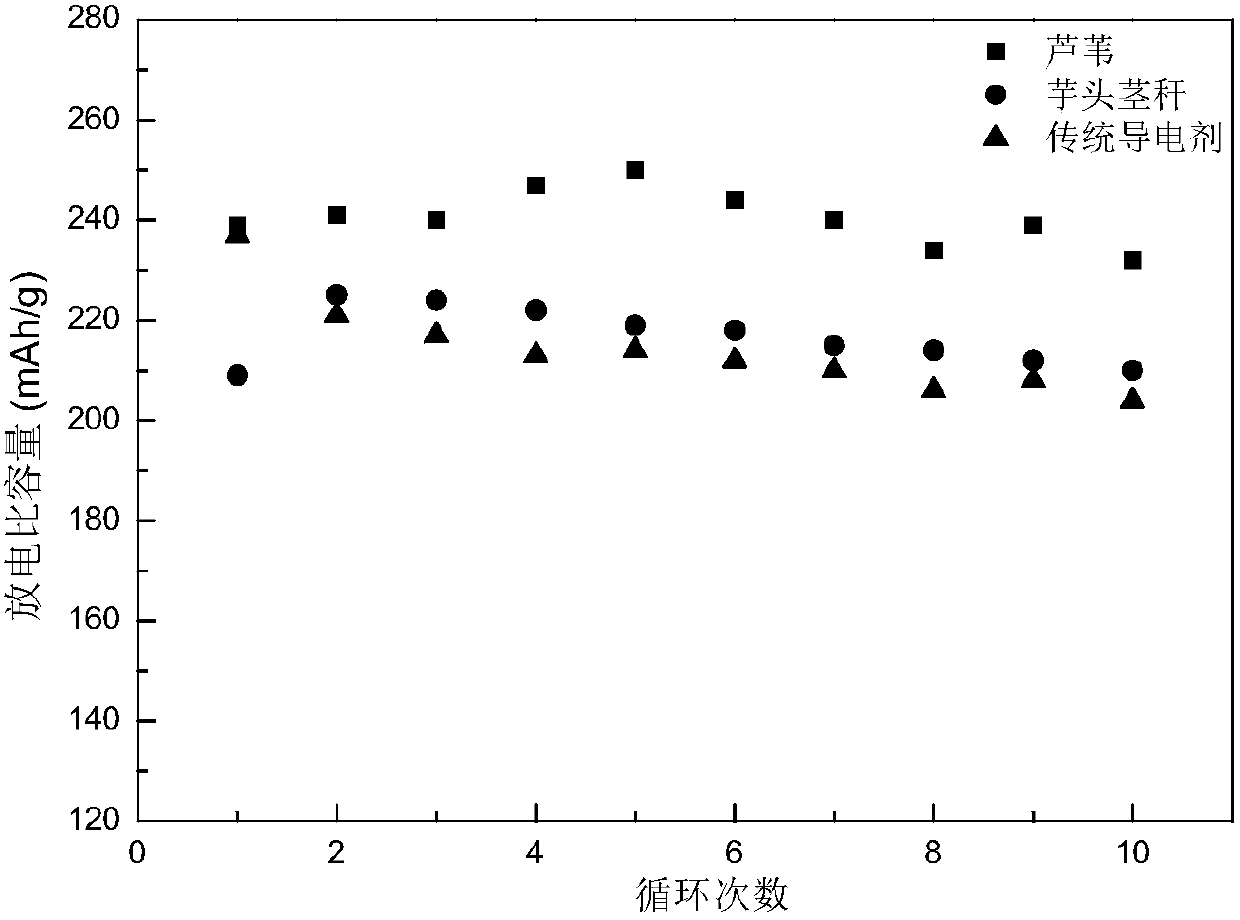

Examples

Embodiment 1

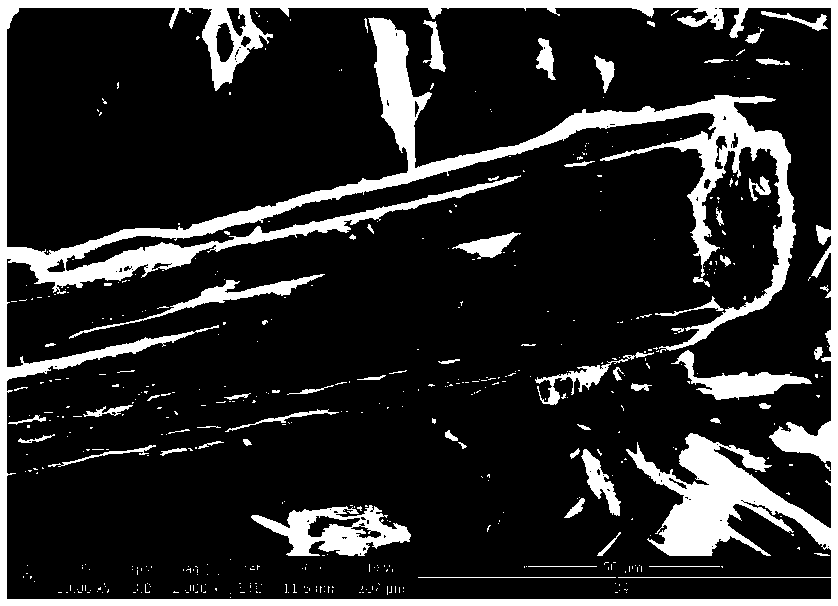

[0033] (1) The collected reeds were ultrasonically cleaned 3 times, each time for 30 minutes to remove impurities, and then dried in a blast drying oven at 60°C for 4 hours, and then placed in a vacuum drying oven and dried at 110°C for 10 hours. Finally, the dried material is pulverized into rods with a length less than 3 cm.

[0034] (2) Under an argon atmosphere, heat to 600° C. for carbonization at a heating rate of 3° C. / min, and hold for 4 hours.

[0035] (3) Add hydrochloric acid to the above-mentioned bio-pyrolytic charcoal, stir at 60°C for 6 hours, wash with deionized water after centrifugation until approximately neutral, and dry overnight at 70°C.

[0036] (4) Add sodium hydroxide solution to the material washed with acid solution, stir at 80°C for 8 hours, wash with deionized water after centrifugation until it is about neutral, and dry at 70°C overnight.

[0037] (5) Add zinc chloride solution, stir at 90°C for 10 hours, wash with deionized water after centrifug...

Embodiment 2

[0046] With the step (1) of embodiment 1.

[0047] (1) Under a nitrogen atmosphere, heat to 800°C at a heating rate of 5°C / min for carbonization, and hold for 4 hours.

[0048] (2) Add nitric acid to the above-mentioned bio-pyrolytic charcoal, stir at 60°C for 6 hours, wash with deionized water after centrifugation until it is about neutral, and dry at 70°C overnight.

[0049] (3) Add potassium hydroxide solution to the material cleaned by acid solution, stir at 80°C for 8 hours, wash with deionized water after centrifugation until it is approximately neutral, and dry overnight at 70°C.

[0050](4) Add potassium carbonate solution, stir at 90° C. for 10 h, wash with deionized water after centrifugation until approximately neutral, and dry at 70° C. overnight.

[0051] (5) Preparation of biochar as an electrode sheet for the negative electrode of the battery: the same as Example 1.

[0052] (6) Preparation of electrode sheet when biochar is used as battery conductive agent: S...

Embodiment 3

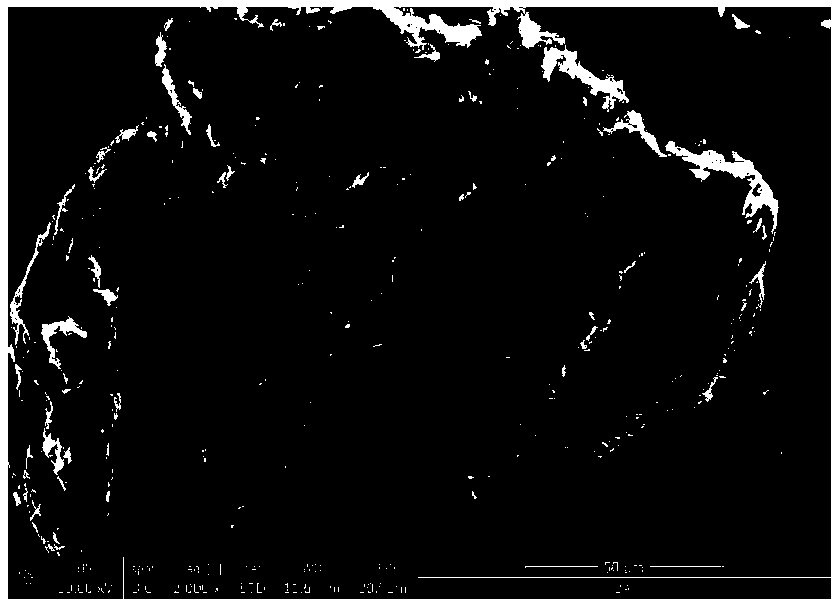

[0055] (1) The collected taro stems were ultrasonically cleaned 5 times, each time for 30 minutes to remove impurities, and then dried in a blast drying oven at 70°C for 5 hours, and then placed in a vacuum drying oven for 12 hours at 110°C. Finally, the dried material is pulverized into rods with a length less than 3 cm.

[0056] (2) Under an argon atmosphere, heat to 600° C. for carbonization at a heating rate of 5° C. / min, and hold for 6 hours.

[0057] (3) Add sulfuric acid to the bio-pyrolytic charcoal, stir at 60°C for 6 hours, wash with deionized water after centrifugation until approximately neutral, and dry overnight at 70°C.

[0058] (4) Add a mixed solution of potassium hydroxide and potassium carbonate to the acid-washed material, stir at 80°C for 12 hours, wash with deionized water after centrifugation until it is approximately neutral, and dry overnight at 70°C.

[0059] (5) Preparation of biochar as an electrode sheet for the negative electrode of the battery: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com