Modified phenolic resin, modified phenolic resin product, preparation methods of modified phenolic resin and modified phenolic resin product and application of modified phenolic resin product

A phenolic resin and modification technology, used in the field of modified phenolic resin, modified phenolic resin products and their preparation, can solve problems such as poor flame retardant performance, carbonization, and oxidation, and achieve excellent mechanical properties and improved flame retardant performance. , the effect of improving the flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

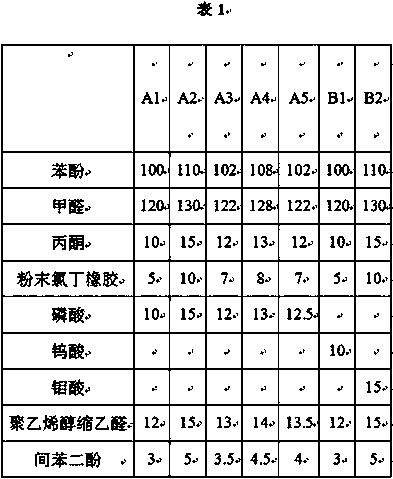

[0064] A1-A5. Preparation of modified phenolic resin:

[0065] a. Dissolve powdered chloroprene rubber in acetone to make liquid A;

[0066] b. Dissolve polyvinyl acetal in formaldehyde to make liquid B;

[0067] c. Dissolve phenol in water at 100°C and add it to the reaction kettle, then add liquid A, formaldehyde and phosphoric acid in sequence, react at a temperature of 60-70°C for 1 hour to generate phosphorus phenolic aldehyde, then lower the temperature by 5°C and add resorcinol Phenol obtains liquid C;

[0068] d. Mix liquid B and liquid C.

[0069] B1. Preparation of modified phenolic resin:

[0070]a. Dissolve powdered chloroprene rubber in acetone to make liquid A;

[0071] b. Dissolve polyvinyl acetal in formaldehyde to make liquid B;

[0072] c. Dissolve phenol in water at 100°C and add it to the reactor, add liquid A, formaldehyde and molybdic acid in sequence, react at a temperature of 60-70°C for 1 hour to form molybdenum phenolic formaldehyde, then lower t...

Embodiment 1-5

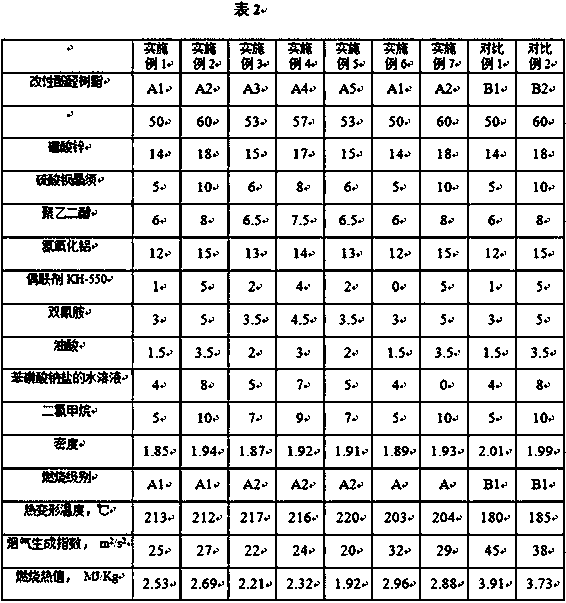

[0081] The preparation of embodiment 1-5 and comparative example 1-2 modified phenolic resin product:

[0082] a. Mix to modified phenolic resin and Polyethylene Glycol, then add oleic acid and methylene dichloride, continue to add the aqueous solution of benzenesulfonic acid sodium salt and coupling agent after stirring and stir to obtain reaction mixture A;

[0083] b. After mixing and dispersing zinc borate, aluminum hydroxide, barium sulfate whiskers and water base, grind into an emulsion mixed solution with a three-roller machine, then add it to the above reaction mixture A and stir to obtain reaction mixture B;

[0084] c. add dicyandiamide to the reaction mixture B, stir into the impregnated phenolic formaldehyde of latex;

[0085] d. The modified phenolic resin product is obtained by pultrusion molding of the impregnated phenolic resin.

[0086] Wherein, the concentration of solute in the aqueous solution of the above-mentioned benzenesulfonic acid sodium salt is 50wt...

Embodiment 6-7

[0088] The preparation of embodiment 6-7 modified phenolic resin products:

[0089] A. the modified phenolic resin and polyethylene glycol are mixed, then add oleic acid and methylene chloride, stir to obtain reaction mixture A;

[0090] b. After mixing and dispersing zinc borate, aluminum hydroxide, barium sulfate whiskers and water base, grind into an emulsion mixed solution with a three-roller machine, then add it to the above reaction mixture A and stir to obtain reaction mixture B;

[0091] c. add dicyandiamide to the reaction mixture B, stir into the impregnated phenolic formaldehyde of latex;

[0092] d. The modified phenolic resin product is obtained by pultrusion molding of the impregnated phenolic resin.

[0093] The various raw materials (in g) and performance data tests in Preparation Examples 1-7 and Comparative Examples 1-2 are shown in Table 2.

[0094]

[0095] From the results in Table 2, it can be seen that the combustion grades in Examples 1-7 of the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat distortion temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap