Spinnable asphalt prepared from coal liquefaction residue, and preparation method thereof, and carbon fiber

A technology of coal liquefaction residue and pitch fiber, which is applied in textiles and papermaking, fiber chemical characteristics, and chemical processing of tar pitch/petroleum pitch/natural pitch, etc., can solve the problems of inappropriate preparation of carbon fiber and inability to inspire carbon fiber, and achieve hydrogen The effect of high content and strong spinnability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

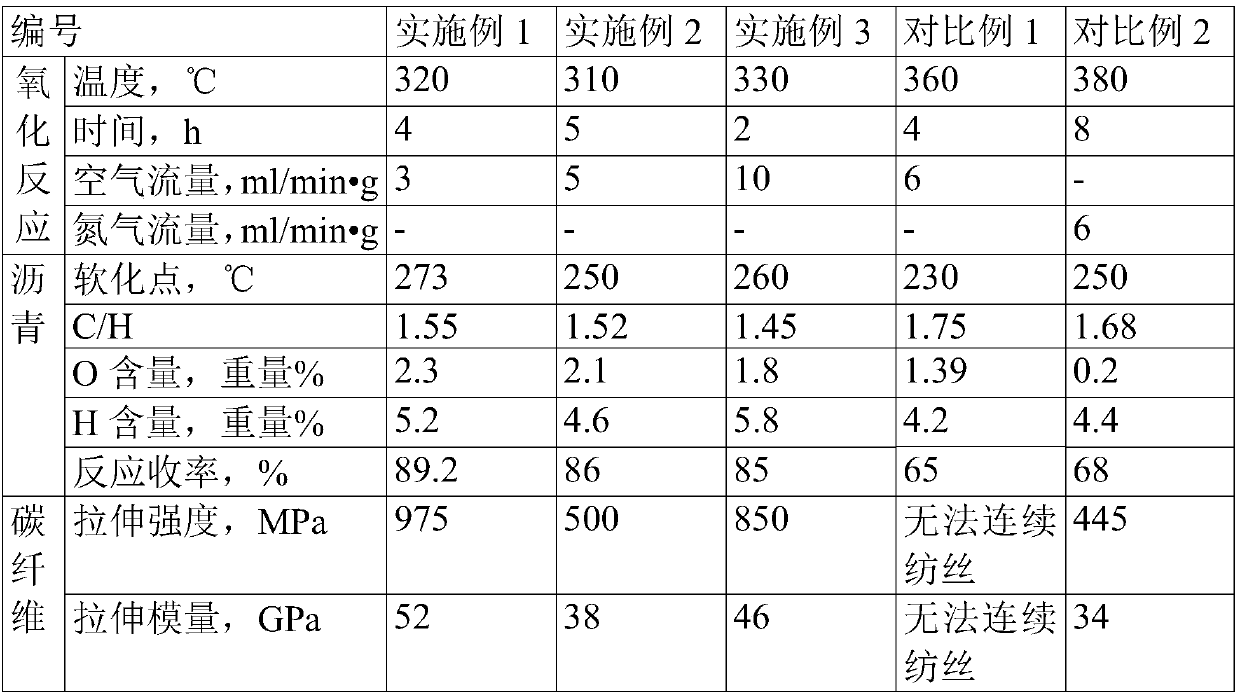

Examples

Embodiment 1

[0064] This example illustrates the preparation of spinnable pitch and carbon fibers from coal liquefaction residue according to the present invention.

[0065] (1) Refined coal liquefaction residue. The coal liquefaction residue (the number average molecular weight is 580, the weight average molecular weight is 700, the softening point is 170°C, the oxygen content is 1% by weight, and the carbon-hydrogen ratio is 1.2:1; Shenhua Coal-to-oil Shanghai Research Institute) and tetrahydrofuran by weight The ratio is 1:2 for mixing, and the mixed product is subjected to hot-melt filtration through a filter. The conditions include: the pore size of the filter element is 50 μm, the filtration temperature is 160 ° C, the pressure is 0.3 MPa, and then the solvent is evaporated to obtain a refined coal liquefaction residue with a softening point of 160 °C, the ash content is 0.01% by weight;

[0066] (2) Spinnable asphalt. Crush 600g of refined coal liquefaction residue into powder, pu...

Embodiment 2

[0074] This example illustrates the preparation of spinnable pitch and carbon fibers from coal liquefaction residue according to the present invention.

[0075] (1) Refined coal liquefaction residue. Coal liquefaction residue (number-average molecular weight 620, weight-average molecular weight 740, softening point 180°C, oxygen content 0% by weight, carbon-hydrogen ratio 1.35:1; Shenhua Coal-to-Liquid Shanghai Research Institute) and coal liquefaction CNPC (Shenhua Coal-to-Oil Shanghai Research Institute) Mixed according to the weight ratio of 1:3, the mixed product is hot-melt filtered through the filter. Evaporated to obtain a refined coal liquefaction residue with a softening point of 175°C and an ash content of 0.03% by weight;

[0076] (2) Spinnable asphalt. Crush 600g of refined coal liquefaction residue into powder, put it into the reaction kettle, and pass air (flow rate: 5ml / min·g), carry out oxidation reaction at 310°C for 5h, heat stirring speed 150r / min, and obt...

Embodiment 3

[0084] This example illustrates the preparation of spinnable pitch and carbon fibers from coal liquefaction residue according to the present invention.

[0085](1) Refined coal liquefaction residue. The coal liquefaction residue (the number average molecular weight is 520, the weight average molecular weight is 640, the softening point is 140°C, the oxygen content is 0.6% by weight, the carbon-hydrogen ratio is 1.15:1; Shenhua Coal-to-oil Shanghai Research Institute) and toluene according to weight The mixture is mixed at a ratio of 1:0.5, and the mixed product is subjected to hot-melt filtration through a filter. The conditions include: the pore size of the filter element is 100 μm, the filtration temperature is 180 ° C, the pressure is 0.6 MPa, and then the solvent is evaporated to obtain a refined coal liquefaction residue with a softening point of 140 °C, the ash content is 0.015% by weight;

[0086] (2) Spinnable asphalt. Crush 600g of refined coal liquefaction residue ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com